Massimo Bergamasco

Design and Kinematic Optimization of a Novel Underactuated Robotic Hand Exoskeleton

May 07, 2020

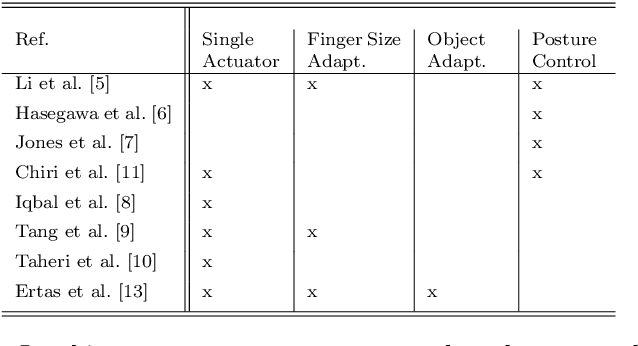

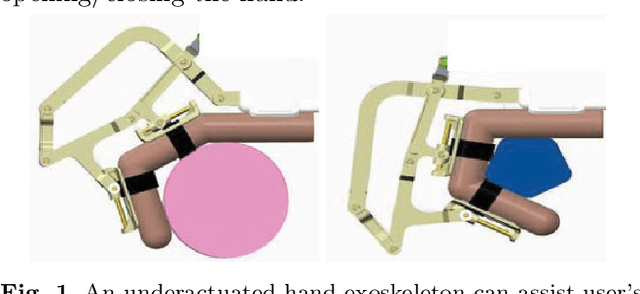

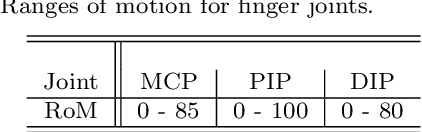

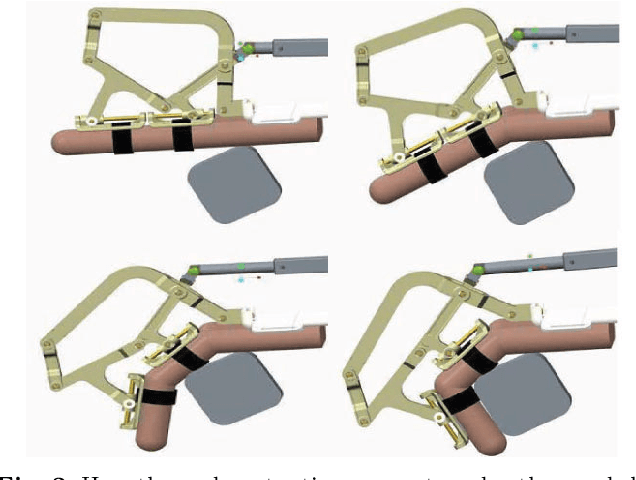

Abstract:This study presents the design and the kinematic optimization of a novel, underactuated, linkage-based robotic hand exoskeleton to assist users in performing grasping tasks. The device has been designed to apply only normal forces to the finger phalanges during flexion/extension of the fingers, while providing automatic adaptability for different finger sizes. Thus, the easiness of the attachment to the user's fingers and better comfort have been ensured. The analyses of the device kinematic pose, statics, and stability of grasp have been performed. These analyses have been used to optimize the link lengths of the mechanism, ensuring that a reasonable range of motion is satisfied while maximizing the force transmission on the finger joints. Finally, the usability of a prototype with multiple fingers has been tested during grasping tasks with different objects.

* 12 pages

A 6-DOF haptic manipulation system to verify assembly procedures on CAD models

Sep 27, 2019

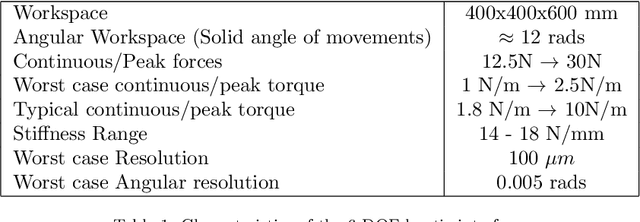

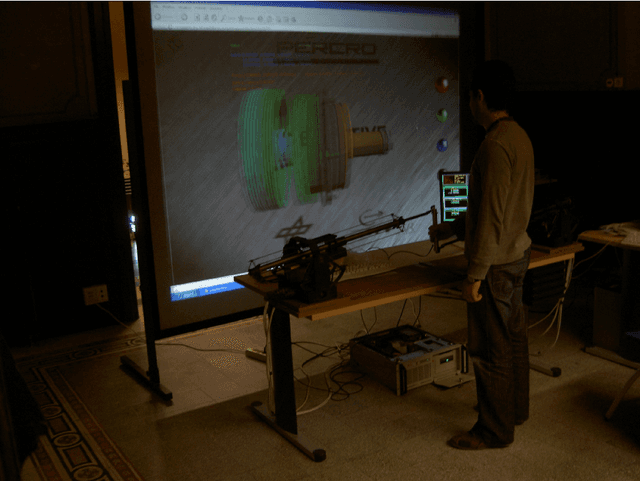

Abstract:During the design phase of products and before going into production, it is necessary to verify the presence of mechanical plays, tolerances, and encumbrances on production mockups. This work introduces a multi-modal system that allows verifying assembly procedures of products in Virtual Reality starting directly from CAD models. Thus leveraging the costs and speeding up the assessment phase in product design. For this purpose, the design of a novel 6-DOF Haptic device is presented. The achieved performance of the system has been validated in a demonstration scenario employing state-of-the-art volumetric rendering of interaction forces together with a stereoscopic visualization setup.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge