Manaswin Oddiraju

Physics-Informed Machine Learning Towards A Real-Time Spacecraft Thermal Simulator

Jul 08, 2024

Abstract:Modeling thermal states for complex space missions, such as the surface exploration of airless bodies, requires high computation, whether used in ground-based analysis for spacecraft design or during onboard reasoning for autonomous operations. For example, a finite-element thermal model with hundreds of elements can take significant time to simulate, which makes it unsuitable for onboard reasoning during time-sensitive scenarios such as descent and landing, proximity operations, or in-space assembly. Further, the lack of fast and accurate thermal modeling drives thermal designs to be more conservative and leads to spacecraft with larger mass and higher power budgets. The emerging paradigm of physics-informed machine learning (PIML) presents a class of hybrid modeling architectures that address this challenge by combining simplified physics models with machine learning (ML) models resulting in models which maintain both interpretability and robustness. Such techniques enable designs with reduced mass and power through onboard thermal-state estimation and control and may lead to improved onboard handling of off-nominal states, including unplanned down-time. The PIML model or hybrid model presented here consists of a neural network which predicts reduced nodalizations (distribution and size of coarse mesh) given on-orbit thermal load conditions, and subsequently a (relatively coarse) finite-difference model operates on this mesh to predict thermal states. We compare the computational performance and accuracy of the hybrid model to a data-driven neural net model, and a high-fidelity finite-difference model of a prototype Earth-orbiting small spacecraft. The PIML based active nodalization approach provides significantly better generalization than the neural net model and coarse mesh model, while reducing computing cost by up to 1.7x compared to the high-fidelity model.

Metamodel Based Forward and Inverse Design for Passive Vibration Suppression

Jul 29, 2020

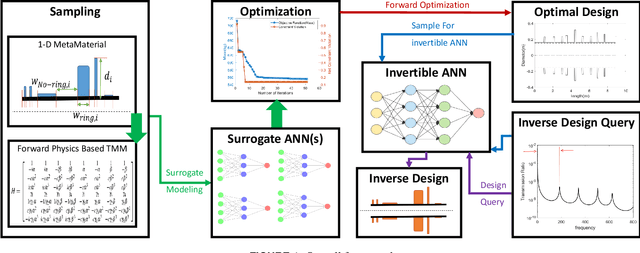

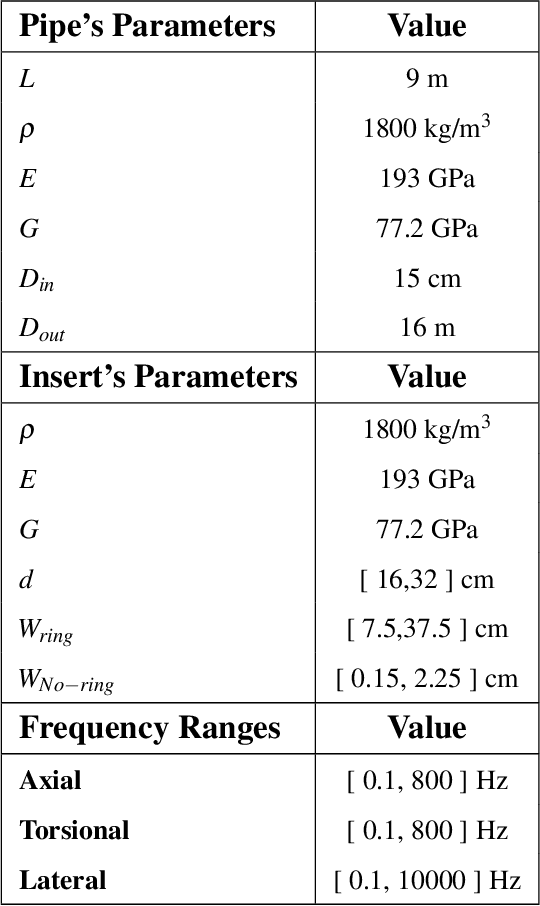

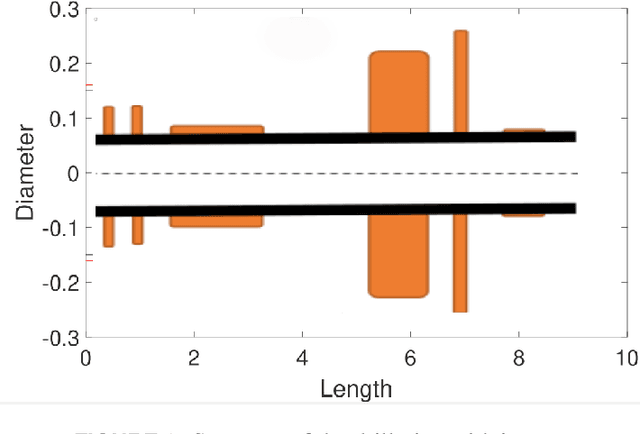

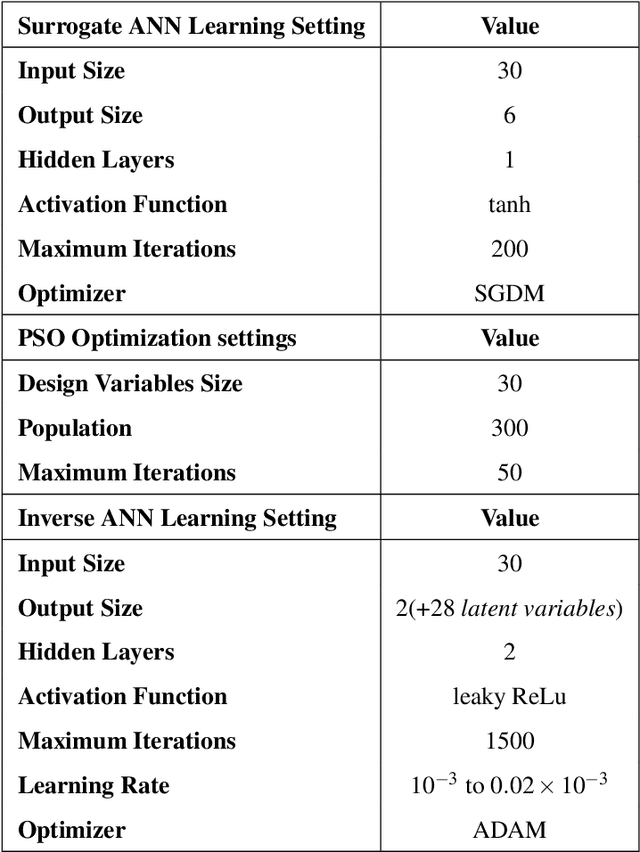

Abstract:Aperiodic metamaterials represent a class of structural systems that are composed of different building blocks (cells), instead of a self-repeating chain of the same unit cells. Optimizing aperiodic cellular structural systems thus presents high-dimensional problems that are challenging to solve using purely high-fidelity structural optimization approaches. Specialized analytical modeling along with metamodel based optimization can provide a more tractable alternative solution approach. To this end, this paper presents a design automation framework applied to a 1D metamaterial system, namely a drill string, where vibration suppression is of utmost importance. The drill string comprises a set of nonuniform rings attached to the outer surface of a longitudinal rod. As such, the resultant system can now be perceived as an aperiodic 1D metamaterial with each ring/gap representing a cell. Despite being a 1D system, the simultaneous consideration of multiple DoF (i.e., torsional, axial, and lateral motions) poses significant computational challenges. Therefore, a transfer matrix method (TMM) is employed to analytically determine the frequency response of the drill string. A suite of neural networks (ANN) is trained on TMM samples (which present minute-scale computing costs per evaluation), to model the frequency response. ANN-based optimization is then performed to minimize mass subject to constraints on the gap between consecutive resonance peaks in one case, and minimizing this gap in the second case, leading to crucial improvements over baselines. Further novel contribution occurs through the development of an inverse modeling approach that can instantaneously produce the 1D metamaterial design with minimum mass for a given desired non-resonant frequency range. This is accomplished by using invertible neural networks, and results show promising alignment with forward solutions.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge