Maarten Witters

Knowledge-Based Support for Adhesive Selection: Will it Stick?

Nov 07, 2023

Abstract:As the popularity of adhesive joints in industry increases, so does the need for tools to support the process of selecting a suitable adhesive. While some such tools already exist, they are either too limited in scope, or offer too little flexibility in use. This work presents a more advanced tool, that was developed together with a team of adhesive experts. We first extract the experts' knowledge about this domain and formalize it in a Knowledge Base (KB). The IDP-Z3 reasoning system can then be used to derive the necessary functionality from this KB. Together with a user-friendly interactive interface, this creates an easy-to-use tool capable of assisting the adhesive experts. To validate our approach, we performed user testing in the form of qualitative interviews. The experts are very positive about the tool, stating that, among others, it will help save time and find more suitable adhesives. Under consideration in Theory and Practice of Logic Programming (TPLP).

Constrained multi-objective optimization of process design parameters in settings with scarce data: an application to adhesive bonding

Dec 16, 2021

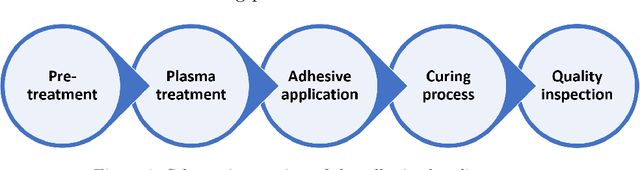

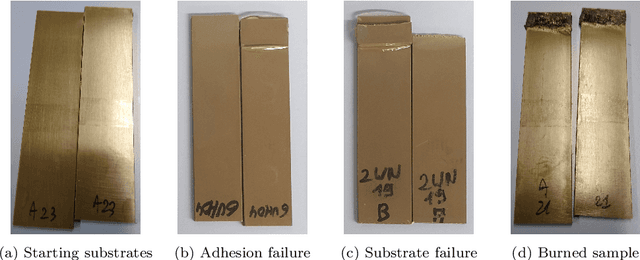

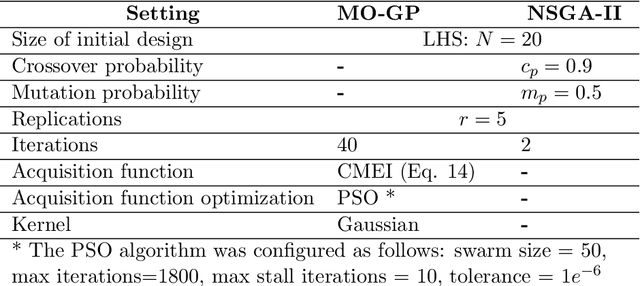

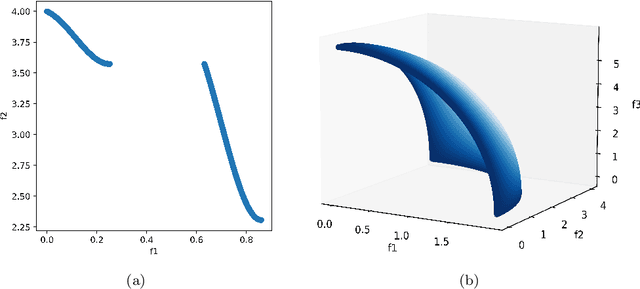

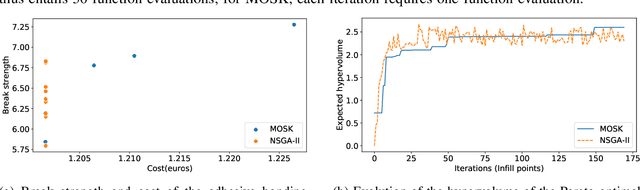

Abstract:Adhesive joints are increasingly used in industry for a wide variety of applications because of their favorable characteristics such as high strength-to-weight ratio, design flexibility, limited stress concentrations, planar force transfer, good damage tolerance and fatigue resistance. Finding the optimal process parameters for an adhesive bonding process is challenging: the optimization is inherently multi-objective (aiming to maximize break strength while minimizing cost) and constrained (the process should not result in any visual damage to the materials, and stress tests should not result in failures that are adhesion-related). Real life physical experiments in the lab are expensive to perform; traditional evolutionary approaches (such as genetic algorithms) are then ill-suited to solve the problem, due to the prohibitive amount of experiments required for evaluation. In this research, we successfully applied specific machine learning techniques (Gaussian Process Regression and Logistic Regression) to emulate the objective and constraint functions based on a limited amount of experimental data. The techniques are embedded in a Bayesian optimization algorithm, which succeeds in detecting Pareto-optimal process settings in a highly efficient way (i.e., requiring a limited number of extra experiments).

Multi-objective simulation optimization of the adhesive bonding process of materials

Dec 09, 2021

Abstract:Automotive companies are increasingly looking for ways to make their products lighter, using novel materials and novel bonding processes to join these materials together. Finding the optimal process parameters for such adhesive bonding process is challenging. In this research, we successfully applied Bayesian optimization using Gaussian Process Regression and Logistic Regression, to efficiently (i.e., requiring few experiments) guide the design of experiments to the Pareto-optimal process parameter settings.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge