Lina María Amaya-Mejía

Visual Servoing for Robotic On-Orbit Servicing: A Survey

Sep 03, 2024Abstract:On-orbit servicing (OOS) activities will power the next big step for sustainable exploration and commercialization of space. Developing robotic capabilities for autonomous OOS operations is a priority for the space industry. Visual Servoing (VS) enables robots to achieve the precise manoeuvres needed for critical OOS missions by utilizing visual information for motion control. This article presents an overview of existing VS approaches for autonomous OOS operations with space manipulator systems (SMS). We divide the approaches according to their contribution to the typical phases of a robotic OOS mission: a) Recognition, b) Approach, and c) Contact. We also present a discussion on the reviewed VS approaches, identifying current trends. Finally, we highlight the challenges and areas for future research on VS techniques for robotic OOS.

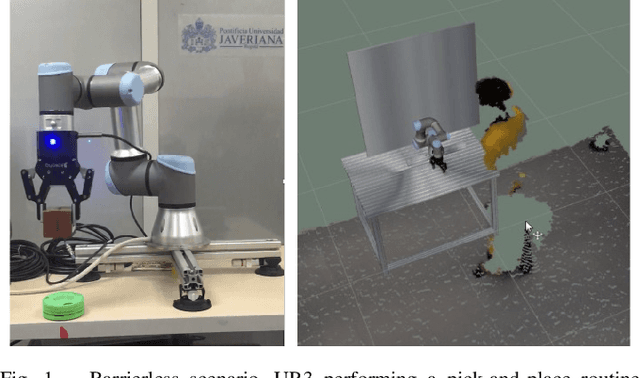

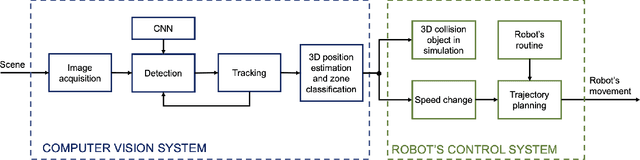

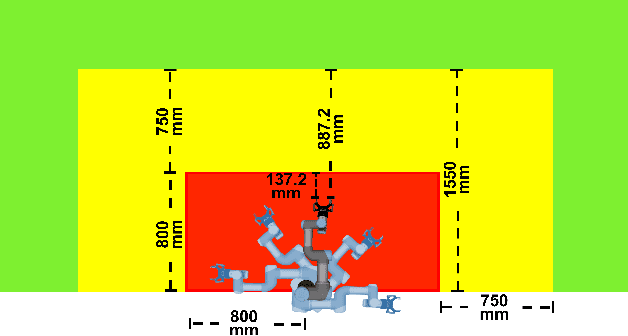

Vision-Based Safety System for Barrierless Human-Robot Collaboration

Aug 03, 2022

Abstract:Human safety has always been the main priority when working near an industrial robot. With the rise of Human-Robot Collaborative environments, physical barriers to avoiding collisions have been disappearing, increasing the risk of accidents and the need for solutions that ensure a safe Human-Robot Collaboration. This paper proposes a safety system that implements Speed and Separation Monitoring (SSM) type of operation. For this, safety zones are defined in the robot's workspace following current standards for industrial collaborative robots. A deep learning-based computer vision system detects, tracks, and estimates the 3D position of operators close to the robot. The robot control system receives the operator's 3D position and generates 3D representations of them in a simulation environment. Depending on the zone where the closest operator was detected, the robot stops or changes its operating speed. Three different operation modes in which the human and robot interact are presented. Results show that the vision-based system can correctly detect and classify in which safety zone an operator is located and that the different proposed operation modes ensure that the robot's reaction and stop time are within the required time limits to guarantee safety.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge