Justinas Miseikis

Lio -- A Personal Robot Assistant for Human-Robot Interaction and Care Applications

Jun 16, 2020

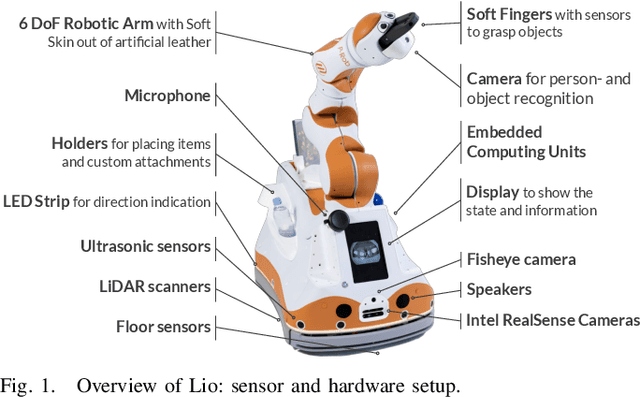

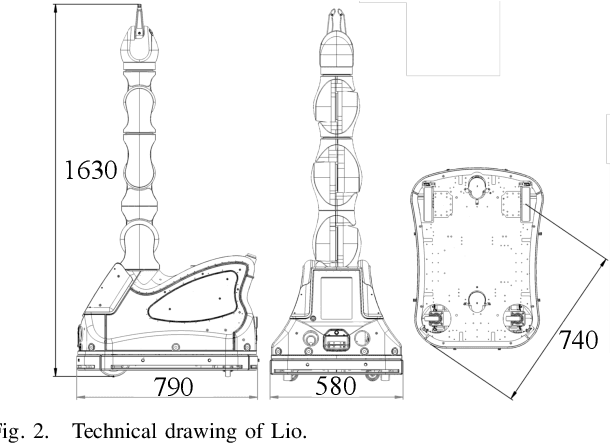

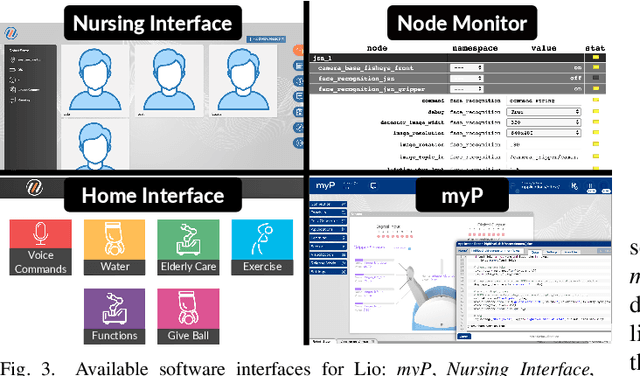

Abstract:Lio is a mobile robot platform with a multi-functional arm explicitly designed for human-robot interaction and personal care assistant tasks. The robot has already been deployed in several health care facilities, where it is functioning autonomously, assisting staff and patients on an everyday basis. Lio is intrinsically safe by having full coverage in soft artificial-leather material as well as having collision detection, limited speed and forces. Furthermore, the robot has a compliant motion controller. A combination of visual, audio, laser, ultrasound and mechanical sensors are used for safe navigation and environment understanding. The ROS-enabled setup allows researchers to access raw sensor data as well as have direct control of the robot. The friendly appearance of Lio has resulted in the robot being well accepted by health care staff and patients. Fully autonomous operation is made possible by a flexible decision engine, autonomous navigation and automatic recharging. Combined with time-scheduled task triggers, this allows Lio to operate throughout the day, with a battery life of up to 8 hours and recharging during idle times. A combination of powerful on-board computing units provides enough processing power to deploy artificial intelligence and deep learning-based solutions on-board the robot without the need to send any sensitive data to cloud services, guaranteeing compliance with privacy requirements. During the COVID-19 pandemic, Lio was rapidly adjusted to perform additional functionality like disinfection and remote elevated body temperature detection. It complies with ISO13482 - Safety requirements for personal care robots, meaning it can be directly tested and deployed in care facilities.

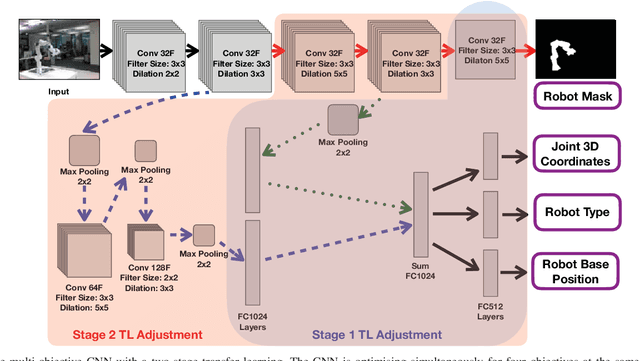

Two-Stage Transfer Learning for Heterogeneous Robot Detection and 3D Joint Position Estimation in a 2D Camera Image using CNN

Feb 15, 2019

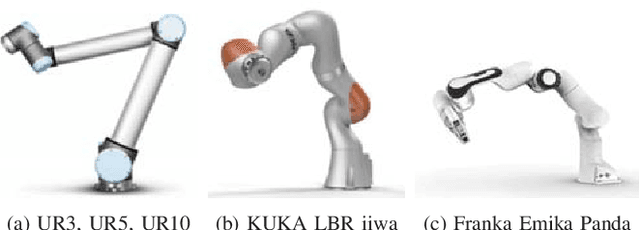

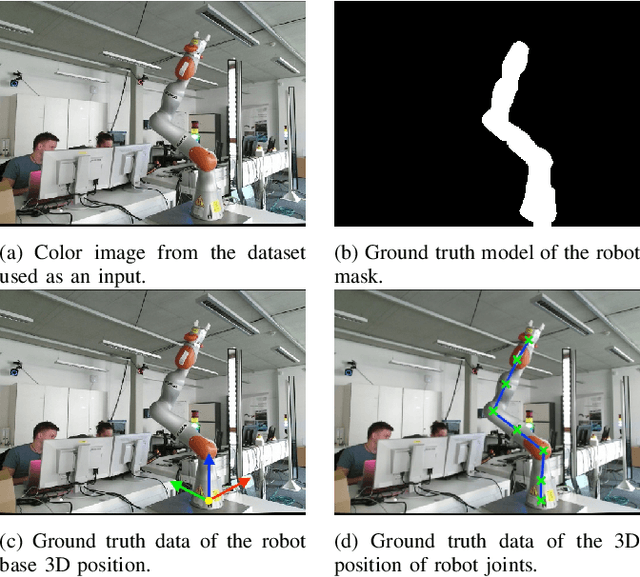

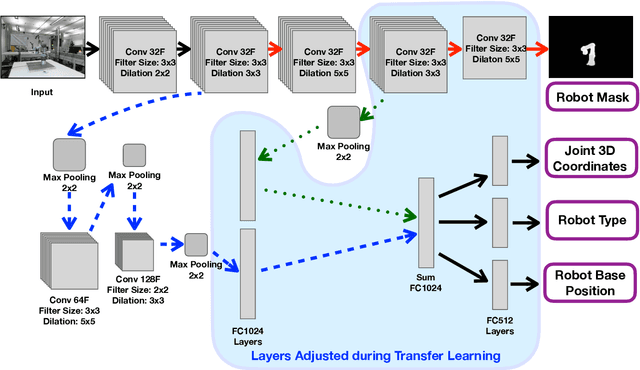

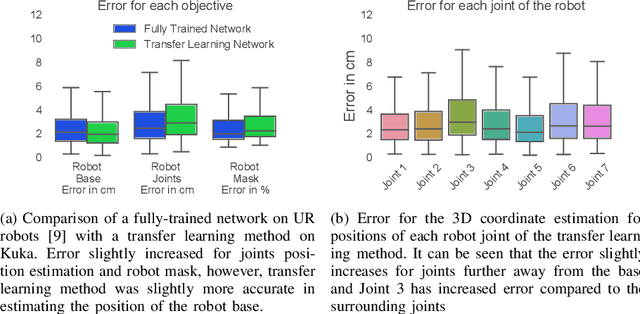

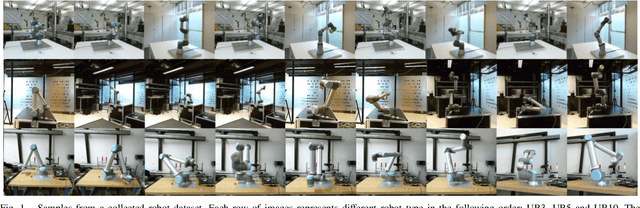

Abstract:Collaborative robots are becoming more common on factory floors as well as regular environments, however, their safety still is not a fully solved issue. Collision detection does not always perform as expected and collision avoidance is still an active research area. Collision avoidance works well for fixed robot-camera setups, however, if they are shifted around, Eye-to-Hand calibration becomes invalid making it difficult to accurately run many of the existing collision avoidance algorithms. We approach the problem by presenting a stand-alone system capable of detecting the robot and estimating its position, including individual joints, by using a simple 2D colour image as an input, where no Eye-to-Hand calibration is needed. As an extension of previous work, a two-stage transfer learning approach is used to re-train a multi-objective convolutional neural network (CNN) to allow it to be used with heterogeneous robot arms. Our method is capable of detecting the robot in real-time and new robot types can be added by having significantly smaller training datasets compared to the requirements of a fully trained network. We present data collection approach, the structure of the multi-objective CNN, the two-stage transfer learning training and test results by using real robots from Universal Robots, Kuka, and Franka Emika. Eventually, we analyse possible application areas of our method together with the possible improvements.

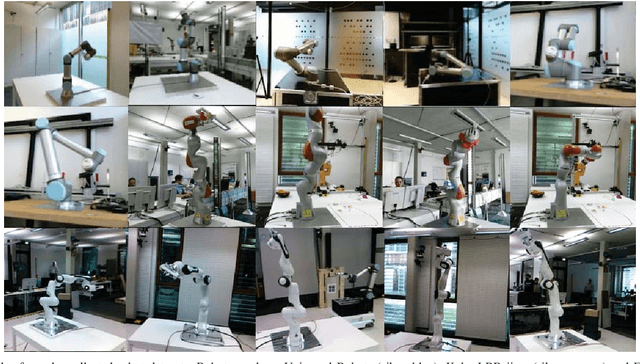

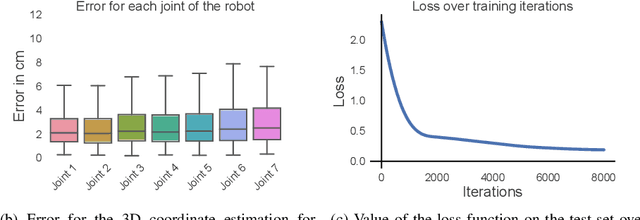

Transfer Learning for Unseen Robot Detection and Joint Estimation on a Multi-Objective Convolutional Neural Network

Jun 11, 2018

Abstract:A significant problem of using deep learning techniques is the limited amount of data available for training. There are some datasets available for the popular problems like item recognition and classification or self-driving cars, however, it is very limited for the industrial robotics field. In previous work, we have trained a multi-objective Convolutional Neural Network (CNN) to identify the robot body in the image and estimate 3D positions of the joints by using just a 2D image, but it was limited to a range of robots produced by Universal Robots (UR). In this work, we extend our method to work with a new robot arm - Kuka LBR iiwa, which has a significantly different appearance and an additional joint. However, instead of collecting large datasets once again, we collect a number of smaller datasets containing a few hundred frames each and use transfer learning techniques on the CNN trained on UR robots to adapt it to a new robot having different shapes and visual features. We have proven that transfer learning is not only applicable in this field, but it requires smaller well-prepared training datasets, trains significantly faster and reaches similar accuracy compared to the original method, even improving it on some aspects.

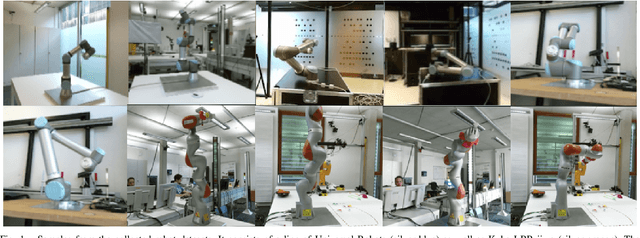

Robot Localisation and 3D Position Estimation Using a Free-Moving Camera and Cascaded Convolutional Neural Networks

May 30, 2018

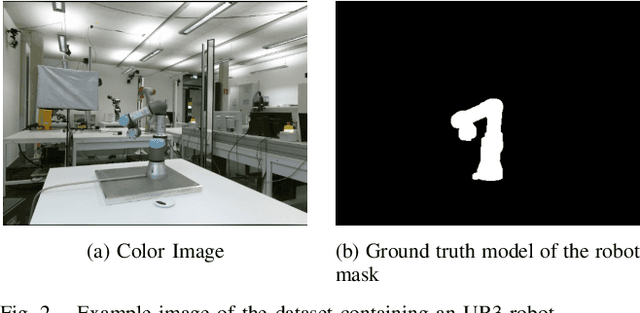

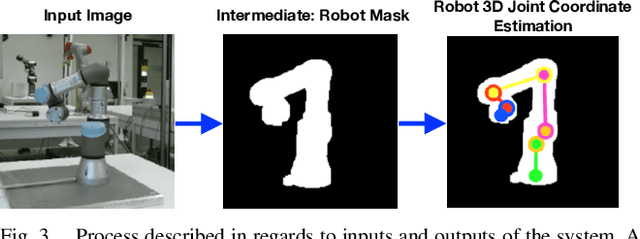

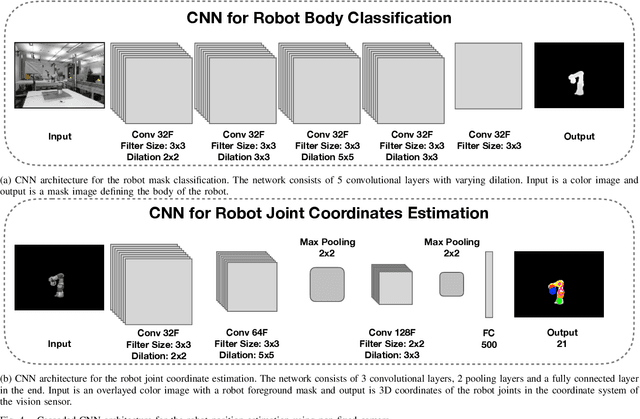

Abstract:Many works in collaborative robotics and human-robot interaction focuses on identifying and predicting human behaviour while considering the information about the robot itself as given. This can be the case when sensors and the robot are calibrated in relation to each other and often the reconfiguration of the system is not possible, or extra manual work is required. We present a deep learning based approach to remove the constraint of having the need for the robot and the vision sensor to be fixed and calibrated in relation to each other. The system learns the visual cues of the robot body and is able to localise it, as well as estimate the position of robot joints in 3D space by just using a 2D color image. The method uses a cascaded convolutional neural network, and we present the structure of the network, describe our own collected dataset, explain the network training and achieved results. A fully trained system shows promising results in providing an accurate mask of where the robot is located and a good estimate of its joints positions in 3D. The accuracy is not good enough for visual servoing applications yet, however, it can be sufficient for general safety and some collaborative tasks not requiring very high precision. The main benefit of our method is the possibility of the vision sensor to move freely. This allows it to be mounted on moving objects, for example, a body of the person or a mobile robot working in the same environment as the robots are operating in.

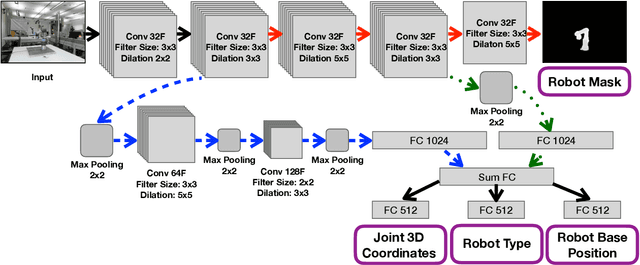

Multi-Objective Convolutional Neural Networks for Robot Localisation and 3D Position Estimation in 2D Camera Images

May 30, 2018

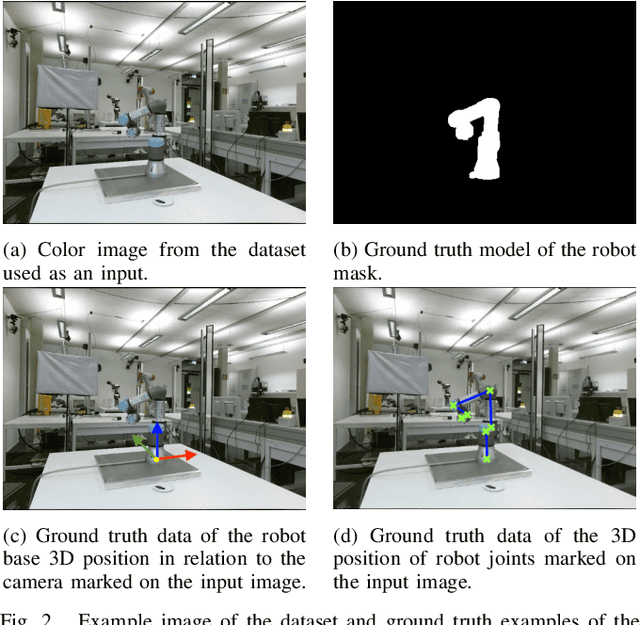

Abstract:The field of collaborative robotics and human-robot interaction often focuses on the prediction of human behaviour, while assuming the information about the robot setup and configuration being known. This is often the case with fixed setups, which have all the sensors fixed and calibrated in relation to the rest of the system. However, it becomes a limiting factor when the system needs to be reconfigured or moved. We present a deep learning approach, which aims to solve this issue. Our method learns to identify and precisely localise the robot in 2D camera images, so having a fixed setup is no longer a requirement and a camera can be moved. In addition, our approach identifies the robot type and estimates the 3D position of the robot base in the camera image as well as 3D positions of each of the robot joints. Learning is done by using a multi-objective convolutional neural network with four previously mentioned objectives simultaneously using a combined loss function. The multi-objective approach makes the system more flexible and efficient by reusing some of the same features and diversifying for each objective in lower layers. A fully trained system shows promising results in providing an accurate mask of where the robot is located and an estimate of its base and joint positions in 3D. We compare the results to our previous approach of using cascaded convolutional neural networks.

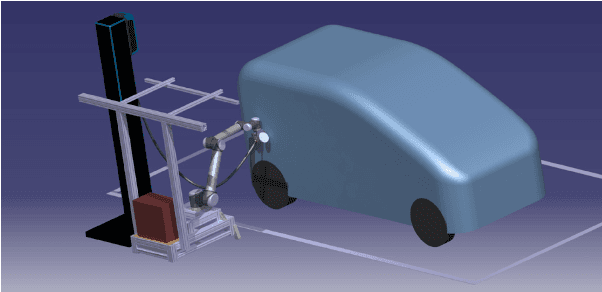

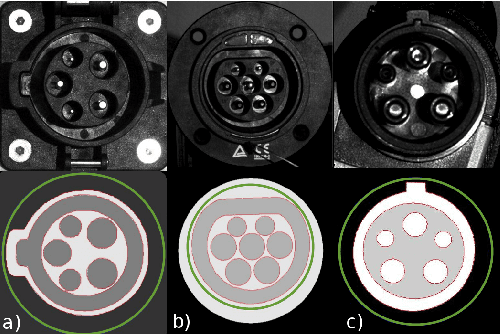

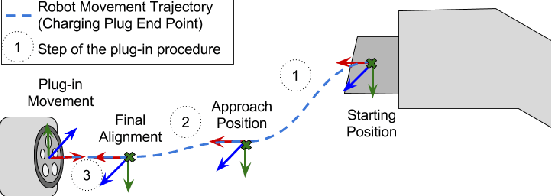

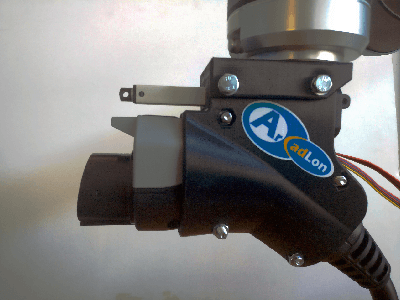

3D Vision Guided Robotic Charging Station for Electric and Plug-in Hybrid Vehicles

Mar 15, 2017

Abstract:Electric vehicles (EVs) and plug-in hybrid vehicles (PHEVs) are rapidly gaining popularity on our roads. Besides a comparatively high purchasing price, the main two problems limiting their use are the short driving range and inconvenient charging process. In this paper we address the following by presenting an automatic robot-based charging station with 3D vision guidance for plugging and unplugging the charger. First of all, the whole system concept consisting of a 3D vision system, an UR10 robot and a charging station is presented. Then we show the shape-based matching methods used to successfully identify and get the exact pose of the charging port. The same approach is used to calibrate the camera-robot system by using just known structure of the connector plug and no additional markers. Finally, a three-step robot motion planning procedure for plug-in is presented and functionality is demonstrated in a series of successful experiments.

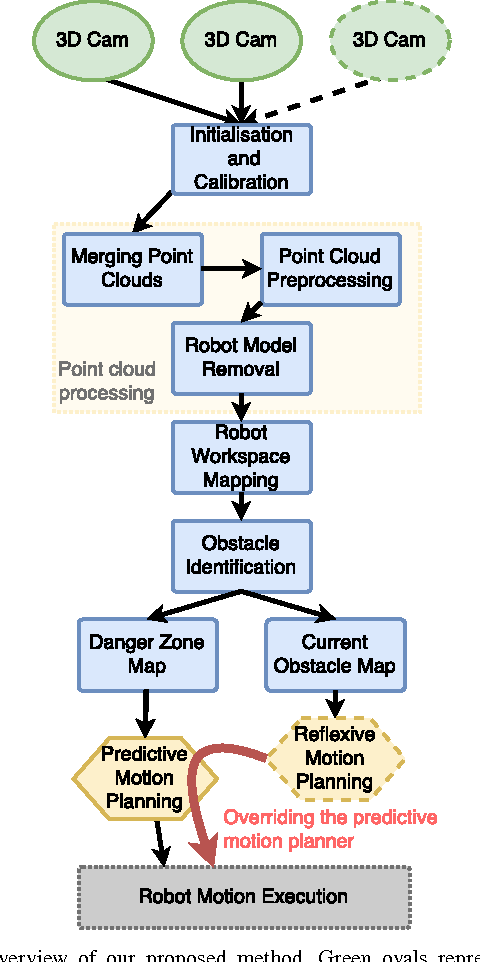

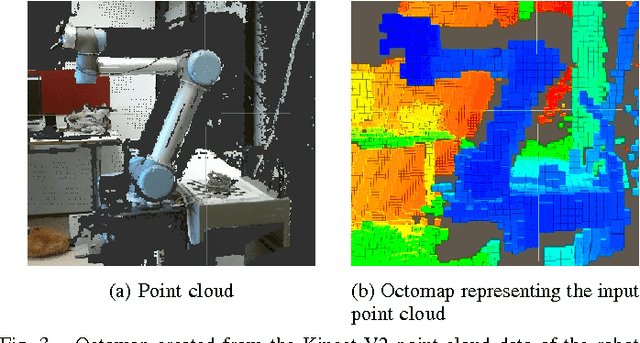

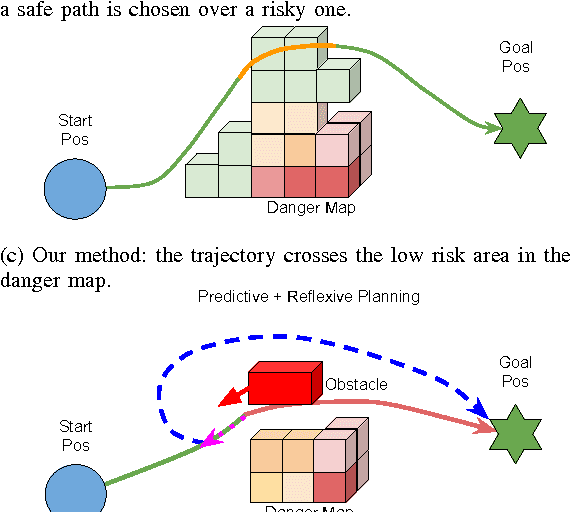

Multi 3D Camera Mapping for Predictive and Reflexive Robot Manipulator Trajectory Estimation

Oct 12, 2016

Abstract:With advancing technologies, robotic manipulators and visual environment sensors are becoming cheaper and more widespread. However, robot control can be still a limiting factor for better adaptation of these technologies. Robotic manipulators are performing very well in structured workspaces, but do not adapt well to unexpected changes, like people entering the workspace. We present a method combining 3D Camera based workspace mapping, and a predictive and reflexive robot manipulator trajectory estimation to allow more efficient and safer operation in dynamic workspaces. In experiments on a real UR5 robot our method has proven to provide shorter and smoother trajectories compared to a reactive trajectory planner in the same conditions. Furthermore, the robot has successfully avoided any contact by initialising the reflexive movement even when an obstacle got unexpectedly close to the robot. The main goal of our work is to make the operation more flexible in unstructured dynamic workspaces and not just avoid obstacles, but also adapt when performing collaborative tasks with humans in the near future.

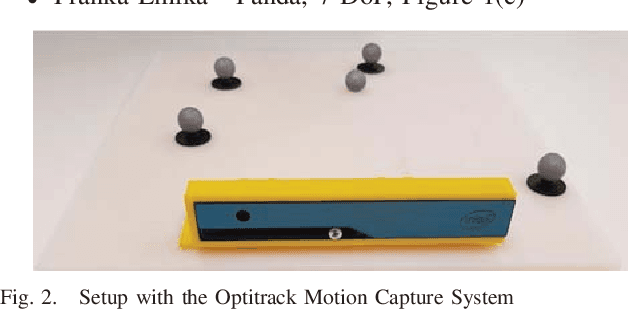

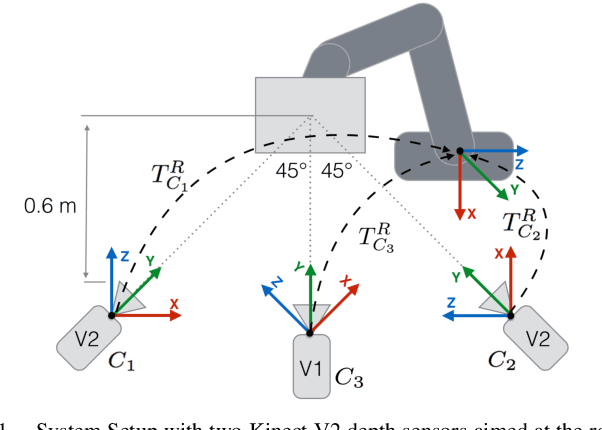

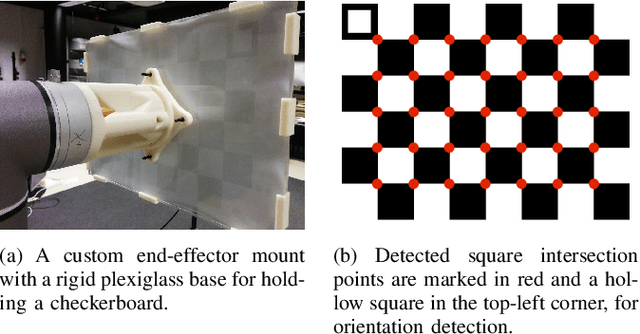

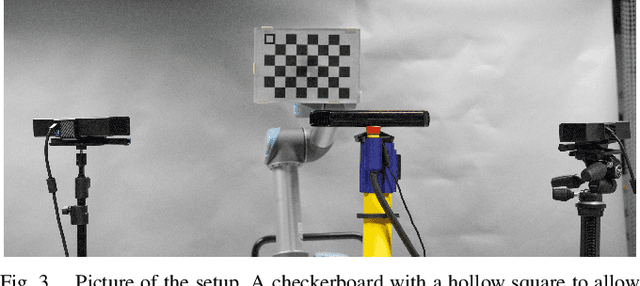

Automatic Calibration of a Robot Manipulator and Multi 3D Camera System

Oct 12, 2016

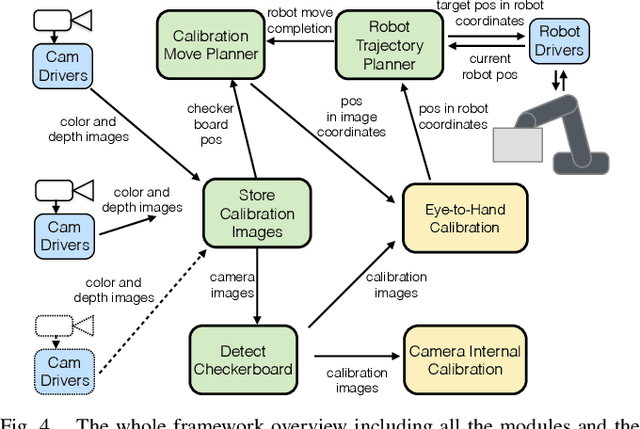

Abstract:With 3D sensing becoming cheaper, environment-aware and visually-guided robot arms capable of safely working in collaboration with humans will become common. However, a reliable calibration is needed, both for camera internal calibration, as well as Eye-to-Hand calibration, to make sure the whole system functions correctly. We present a framework, using a novel combination of well proven methods, allowing a quick automatic calibration for the integration of systems consisting of the robot and a varying number of 3D cameras by using a standard checkerboard calibration grid. Our approach allows a quick camera-to-robot recalibration after any changes to the setup, for example when cameras or robot have been repositioned. Modular design of the system ensures flexibility regarding a number of sensors used as well as different hardware choices. The framework has been proven to work by practical experiments to analyze the quality of the calibration versus the number of positions of the checkerboard used for each of the calibration procedures.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge