Mario Hirz

Root Cause Analysis in Lithium-Ion Battery Production with FMEA-Based Large-Scale Bayesian Network

Jun 15, 2020

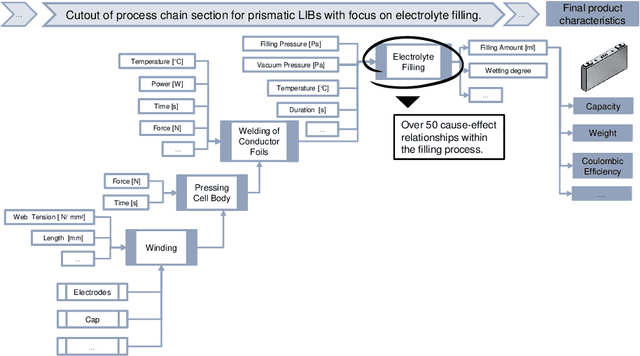

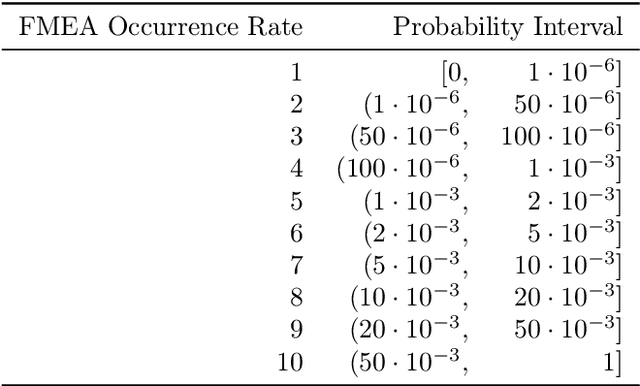

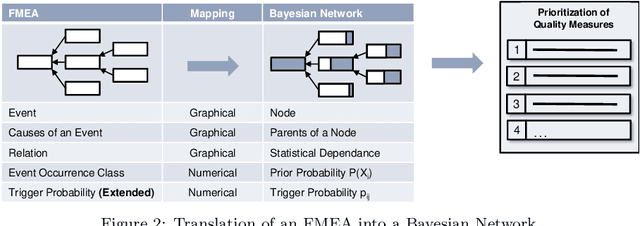

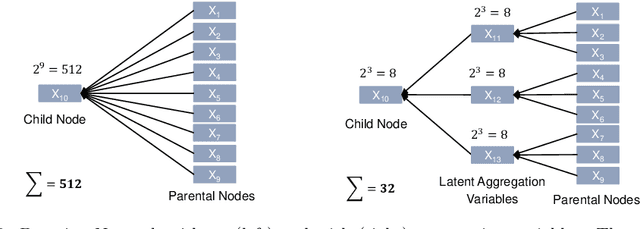

Abstract:The production of lithium-ion battery cells is characterized by a high degree of complexity due to numerous cause-effect relationships between process characteristics. Knowledge about the multi-stage production is spread among several experts, rendering tasks as failure analysis challenging. In this paper, a new method is presented that includes expert knowledge acquisition in production ramp-up by combining Failure Mode and Effects Analysis (FMEA) with a Bayesian Network. Special algorithms are presented that help detect and resolve inconsistencies between the expert-provided parameters which are bound to occur when collecting knowledge from several process experts. We show the effectiveness of this holistic method by building up a large scale, cross-process Bayesian Failure Network in lithium-ion battery production and its application for root cause analysis.

3D Vision Guided Robotic Charging Station for Electric and Plug-in Hybrid Vehicles

Mar 15, 2017

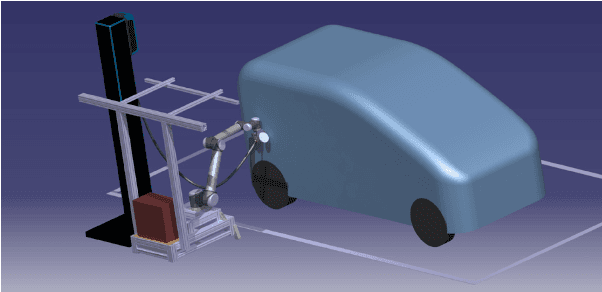

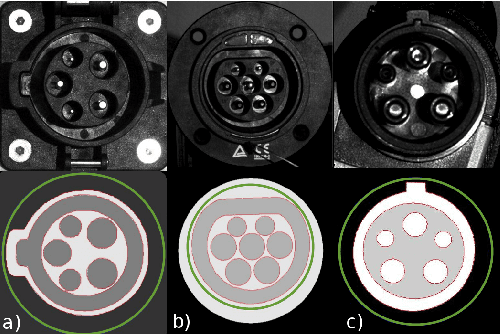

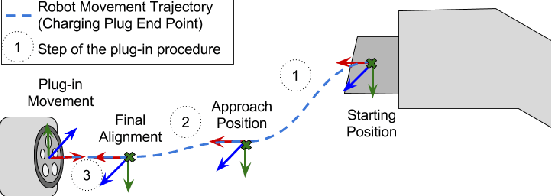

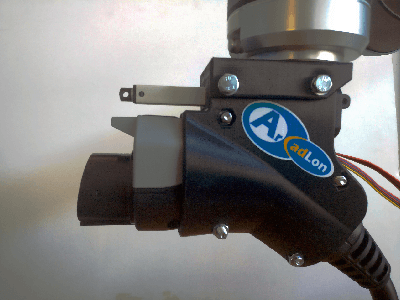

Abstract:Electric vehicles (EVs) and plug-in hybrid vehicles (PHEVs) are rapidly gaining popularity on our roads. Besides a comparatively high purchasing price, the main two problems limiting their use are the short driving range and inconvenient charging process. In this paper we address the following by presenting an automatic robot-based charging station with 3D vision guidance for plugging and unplugging the charger. First of all, the whole system concept consisting of a 3D vision system, an UR10 robot and a charging station is presented. Then we show the shape-based matching methods used to successfully identify and get the exact pose of the charging port. The same approach is used to calibrate the camera-robot system by using just known structure of the connector plug and no additional markers. Finally, a three-step robot motion planning procedure for plug-in is presented and functionality is demonstrated in a series of successful experiments.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge