Junhyoung Ha

Incorporating General Contact Surfaces in the Kinematics of Tendon-Driven Rolling-Contact Joint Mechanisms

Sep 01, 2024Abstract:This paper presents the first kinematic modeling of tendon-driven rolling-contact joint mechanisms with general contact surfaces subject to external loads. We derived the kinematics as a set of recursive equations and developed efficient iterative algorithms to solve for both tendon force actuation and tendon displacement actuation. The configuration predictions of the kinematics were experimentally validated using a prototype mechanism. Our MATLAB implementation of the proposed kinematic is available at https://github.com/hjhdog1/RollingJoint.

Generative Adversarial Networks for Solving Hand-Eye Calibration without Data Correspondence

Aug 10, 2024

Abstract:In this study, we rediscovered the framework of generative adversarial networks (GANs) as a solver for calibration problems without data correspondence. When data correspondence is not present or loosely established, the calibration problem becomes a parameter estimation problem that aligns the two data distributions. This procedure is conceptually identical to the underlying principle of GAN training in which networks are trained to match the generative distribution to the real data distribution. As a primary application, this idea is applied to the hand-eye calibration problem, demonstrating the proposed method's applicability and benefits in complicated calibration problems.

Development of Tendon-Driven Compliant Snake Robot with Global Bending and Twisting Actuation

Jul 22, 2024

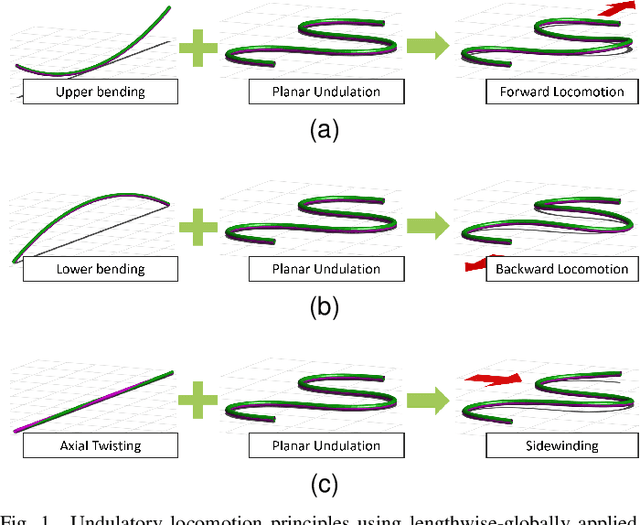

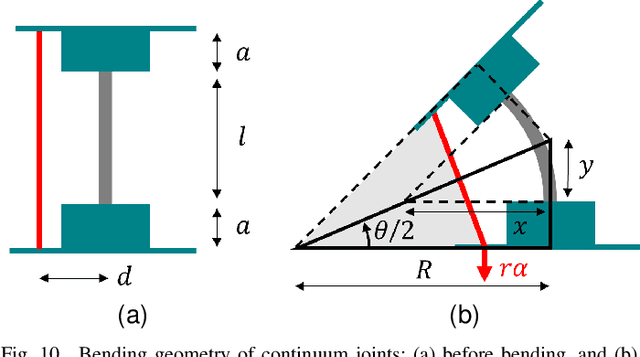

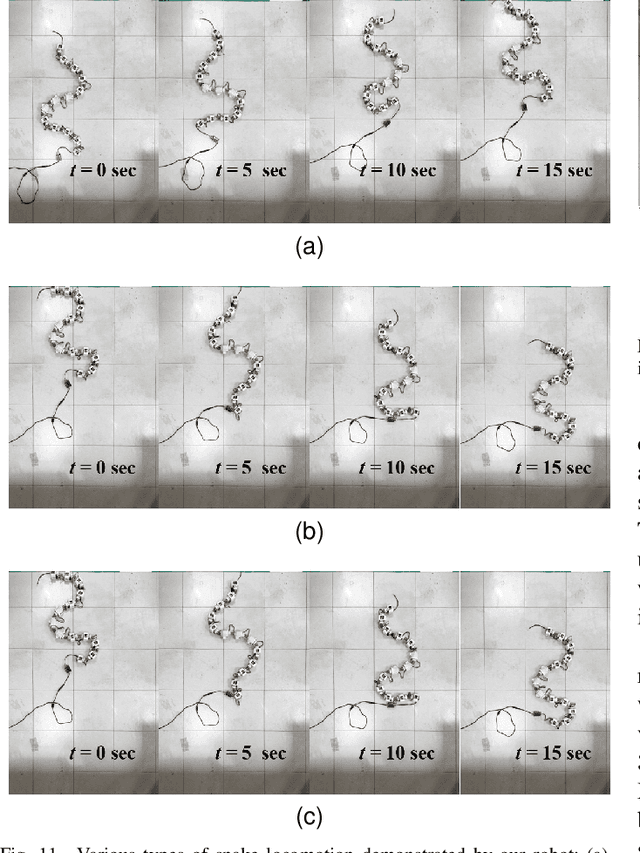

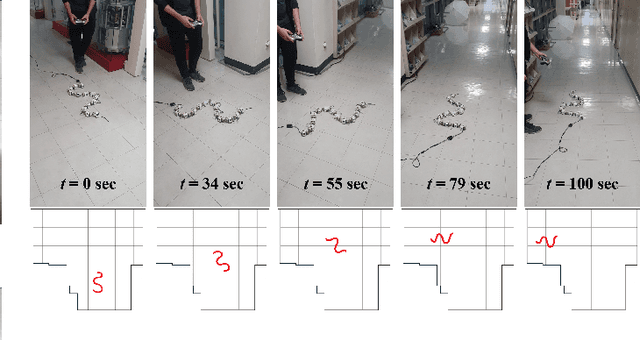

Abstract:Snake robots have been studied for decades with the aim of achieving biological snakes' fluent locomotion. Yet, as of today, their locomotion remains far from that of the biological snakes. Our recent study suggested that snake locomotion utilizing partial ground contacts can be achieved with robots by using body compliance and lengthwise-globally applied body tensions. In this paper, we present the first hardware implementation of this locomotion principle. Our snake robot comprises serial tendon-driven continuum sections and is bent and twisted globally using tendons. We demonstrate how the tendons are actuated to achieve the ground contacts for forward and backward locomotion and sidewinding. The robot's capability to generate snake locomotion in various directions and its steerability were validated in a series of indoor experiments.

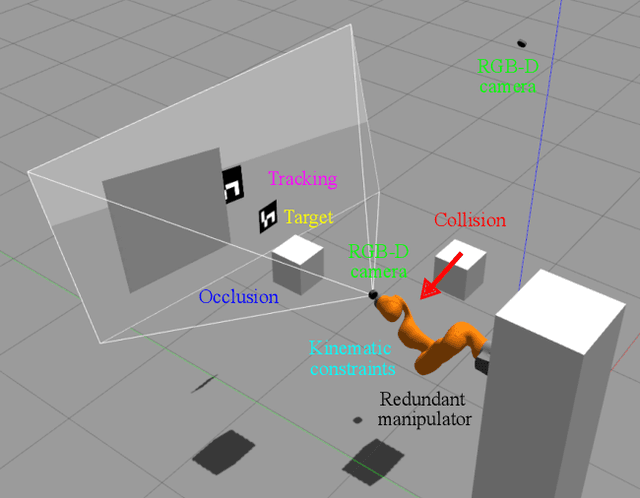

Obstacle- and Occlusion-Responsive Visual Tracking Control for Redundant Manipulators using Reachability Measure

Nov 06, 2023

Abstract:A vision system attached to a manipulator excels at tracing a moving target object while effectively handling obstacles, overcoming limitations arising from the camera's confined field of view and occluded line of sight. Meanwhile, the manipulator may encounter certain challenges, including restricted motion due to kinematic constraints and the risk of colliding with external obstacles. These challenges are typically addressed by assigning multiple task objectives to the manipulator. However, doing so can cause an increased risk of driving the manipulator to its kinematic limits, leading to failures in object tracking or obstacle avoidance. To address this issue, we propose a novel visual tracking control method for a redundant manipulator that takes the kinematic constraints into account via a reachability measure. Our method employs an optimization-based controller that considers object tracking, occlusion avoidance, collision avoidance, and the kinematic constraints represented by the reachability measure. Subsequently, it determines a suitable joint configuration through real-time inverse kinematics, accounting for dynamic obstacle avoidance and the continuity of joint configurations. To validate our approach, we conducted simulations and hardware experiments involving a moving target and dynamic obstacles. The results of our evaluations highlight the significance of incorporating the reachability measure.

Toward Extending Concentric Tube Robot Kinematics for Large Clearance and Impulse Curvature

Aug 21, 2023

Abstract:Concentric Tube Robots (CTRs) have been proposed to operate within the unstructured environment for minimally invasive surgeries. In this letter, we consider the operation scenario where the tubes travel inside the channels with a large clearance or large curvature, such as aortas or industrial pipes. Accurate kinematic modeling of CTRs is required for the development of advanced control and sensing algorithms. To this end, we extended the conventional CTR kinematics model to a more general case with large tube-to-tube clearance and large centerline curvature. Numerical simulations and experimental validations are conducted to compare our model with respect to the conventional CTR kinematic model. In the physical experiments, our proposed model achieved a tip position error of 1.53 mm in the 2D planer case and 4.36 mm in 3D case, outperforming the state-of-the-art model by 71% and 66%, respectively.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge