Julius Schöning

Compliance of AI Systems

Mar 07, 2025Abstract:The increasing integration of artificial intelligence (AI) systems in various fields requires solid concepts to ensure compliance with upcoming legislation. This paper systematically examines the compliance of AI systems with relevant legislation, focusing on the EU's AI Act and the compliance of data sets. The analysis highlighted many challenges associated with edge devices, which are increasingly being used to deploy AI applications closer and closer to the data sources. Such devices often face unique issues due to their decentralized nature and limited computing resources for implementing sophisticated compliance mechanisms. By analyzing AI implementations, the paper identifies challenges and proposes the first best practices for legal compliance when developing, deploying, and running AI. The importance of data set compliance is highlighted as a cornerstone for ensuring the trustworthiness, transparency, and explainability of AI systems, which must be aligned with ethical standards set forth in regulatory frameworks such as the AI Act. The insights gained should contribute to the ongoing discourse on the responsible development and deployment of embedded AI systems.

Agricultural Industry Initiatives on Autonomy: How collaborative initiatives of VDMA and AEF can facilitate complexity in domain crossing harmonization needs

Jan 29, 2025Abstract:The agricultural industry is undergoing a significant transformation with the increasing adoption of autonomous technologies. Addressing complex challenges related to safety and security, components and validation procedures, and liability distribution is essential to facilitate the adoption of autonomous technologies. This paper explores the collaborative groups and initiatives undertaken to address these challenges. These groups investigate inter alia three focal topics: 1) describe the functional architecture of the operational range, 2) define the work context, i.e., the realistic scenarios that emerge in various agricultural applications, and 3) the static and dynamic detection cases that need to be detected by sensor sets. Linked by the Agricultural Operational Design Domain (Agri-ODD), use case descriptions, risk analysis, and questions of liability can be handled. By providing an overview of these collaborative initiatives, this paper aims to highlight the joint development of autonomous agricultural systems that enhance the overall efficiency of farming operations.

Keep Calm and Relax -- HMI for Autonomous Vehicles

Aug 16, 2024Abstract:The growing popularity of self-driving, so-called autonomous vehicles has increased the need for human-machine interfaces~(HMI) and user interaction~(UI) to enhance passenger trust and comfort. While fallback drivers significantly influence the perceived trustfulness of self-driving vehicles, fallback drivers are an expensive solution that may not even improve vehicle safety in emergency situations. Based on a comprehensive literature review, this work delves into the potential of HMI and UI in enhancing trustfulness and emotion regulation in driverless vehicles. By analyzing the impact of various HMI and UI on passenger emotions, innovative and cost-effective concepts for improving human-vehicle interaction are conceptualized. To enable a trustful, highly comfortable, and safe ride, this work concludes by discussing whether HMI and UI are suitable for calming passengers down in emergencies, leading to smarter mobility for all.

AI-Supported Assessment of Load Safety

Jun 06, 2023

Abstract:Load safety assessment and compliance is an essential step in the corporate process of every logistics service provider. In 2020, a total of 11,371 police checks of trucks were carried out, during which 9.6% (1091) violations against the load safety regulations were detected. For a logistic service provider, every load safety violation results in height fines and damage to reputation. An assessment of load safety supported by artificial intelligence (AI) will reduce the risk of accidents by unsecured loads and fines during safety assessments. This work shows how photos of the load, taken by the truck driver or the loadmaster after the loading process, can be used to assess load safety. By a trained two-stage artificial neural network (ANN), these photos are classified into three different classes I) cargo loaded safely, II) cargo loaded unsafely, and III) unusable image. By applying several architectures of convolutional neural networks (CNN), it can be shown that it is possible to distinguish between unusable and usable images for cargo safety assessment. This distinction is quite crucial since the truck driver and the loadmaster sometimes provide photos without the essential image features like the case structure of the truck and the whole cargo. A human operator or another ANN will then assess the load safety within the second stage.

AI-in-the-Loop -- The impact of HMI in AI-based Application

Mar 21, 2023

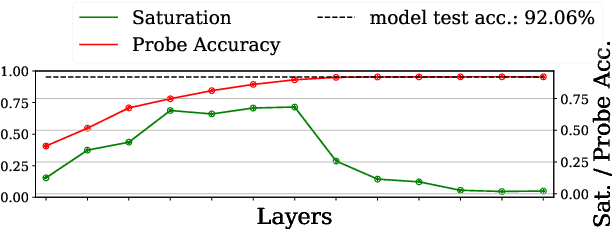

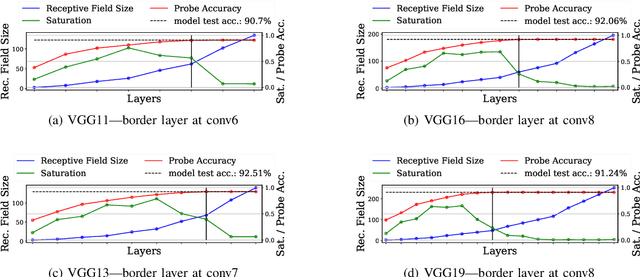

Abstract:Artificial intelligence (AI) and human-machine interaction (HMI) are two keywords that usually do not fit embedded applications. Within the steps needed before applying AI to solve a specific task, HMI is usually missing during the AI architecture design and the training of an AI model. The human-in-the-loop concept is prevalent in all other steps of developing AI, from data analysis via data selection and cleaning to performance evaluation. During AI architecture design, HMI can immediately highlight unproductive layers of the architecture so that lightweight network architecture for embedded applications can be created easily. We show that by using this HMI, users can instantly distinguish which AI architecture should be trained and evaluated first since a high accuracy on the task could be expected. This approach reduces the resources needed for AI development by avoiding training and evaluating AI architectures with unproductive layers and leads to lightweight AI architectures. These resulting lightweight AI architectures will enable HMI while running the AI on an edge device. By enabling HMI during an AI uses inference, we will introduce the AI-in-the-loop concept that combines AI's and humans' strengths. In our AI-in-the-loop approach, the AI remains the working horse and primarily solves the task. If the AI is unsure whether its inference solves the task correctly, it asks the user to use an appropriate HMI. Consequently, AI will become available in many applications soon since HMI will make AI more reliable and explainable.

AI for Closed-Loop Control Systems --- New Opportunities for Modeling, Designing, and Tuning Control Systems

Jan 18, 2022

Abstract:Control Systems, particularly closed-loop control systems (CLCS), are frequently used in production machines, vehicles, and robots nowadays. CLCS are needed to actively align actual values of a process to a given reference or set values in real-time with a very high precession. Yet, artificial intelligence (AI) is not used to model, design, optimize, and tune CLCS. This paper will highlight potential AI-empowered and -based control system designs and designing procedures, gathering new opportunities and research direction in the field of control system engineering. Therefore, this paper illustrates which building blocks within the standard block diagram of CLCS can be replaced by AI, i.e., artificial neuronal networks (ANN). Having processes with real-time contains and functional safety in mind, it is discussed if AI-based controller blocks can cope with these demands. By concluding the paper, the pros and cons of AI-empowered as well as -based CLCS designs are discussed, and possible research directions for introducing AI in the domain of control system engineering are given.

Should You Go Deeper? Optimizing Convolutional Neural Network Architectures without Training by Receptive Field Analysis

Jun 23, 2021

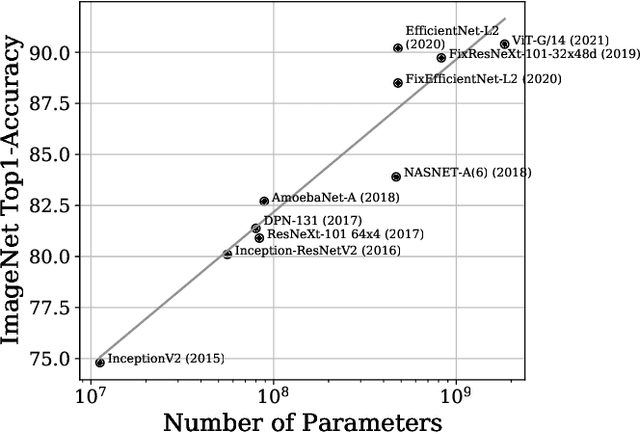

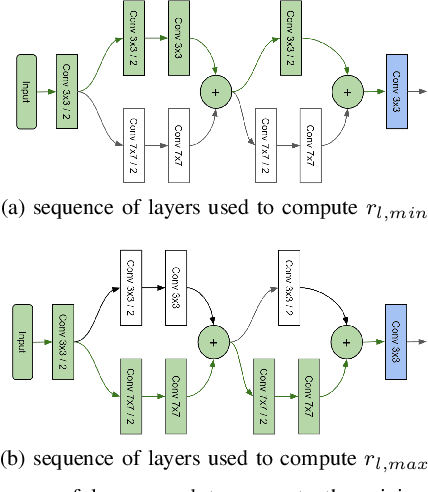

Abstract:Applying artificial neural networks (ANN) to specific tasks, researchers, programmers, and other specialists usually overshot the number of convolutional layers in their designs. By implication, these ANNs hold too many parameters, which needed unnecessarily trained without impacting the result. The features, a convolutional layer can process, are strictly limited by its receptive field. By layer-wise analyzing the expansion of the receptive fields, we can reliably predict sequences of layers that will not contribute qualitatively to the inference in thegiven ANN architecture. Based on these analyses, we propose design strategies to resolve these inefficiencies, optimizing the explainability and the computational performance of ANNs. Since neither the strategies nor the analysis requires training of the actual model, these insights allow for a very efficient design process of ANNs architectures which might be automated in the future.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge