John Franklin

Towards a New Paradigm of UAV Safety

Mar 24, 2018

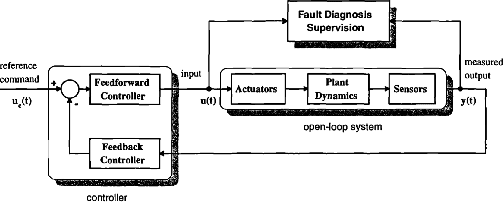

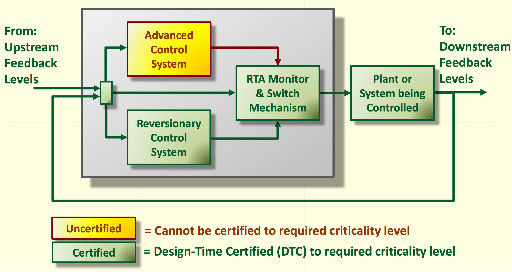

Abstract:With the rising popularity of UAVs in the civilian world, we are currently witnessing and paradim shift in terms of operational safety of flying vehicles. Safe and ubiquitous human-system interaction shall remain the core requirement but those prescribed in general aviation are not adapted for UAVs. Yet we believe it is possible to leverage the specific aspects of unmanned aviation to meet acceptable safety requirements. We start this paper with by discussing the new operational context of civilian UAVs and investigate the meaning of safety in light of this new context. Next, we explore the different approaches to ensuring system safety from an avionics point of view. Subsets of operational requirements such as geofencing or mechanical systems for termination or impact limitation can easily be implemented. These are presented with the goal of limiting the collateral damages of a system failure. We then present some experimental results regarding two of the major problems with UAVs. With actual impacts, we demonstrate how dangerous uncontrolled crashes can be. Furthermore, with the large number of runaway drone experiences during civilian operations, the risk is even higher as they can travel a long way before crashing. We provide data on such a case where the software controller is working, keeping the UAV in the air, but the operator is unable to actually control the system. It should be terminated! Finally, after having analyzed the context and some actual solutions, based on a minimal set of requirement and our own experience, we are proposing a simple mechanical based safety system. It unequivocally terminates the flight in the most efficient way by instantly removing parts of the propellers leaving a minimal lifting surface. It takes advantage of what controllability may remain but with a deterministic ending: a definite landing.

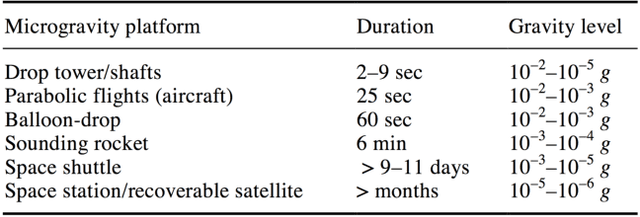

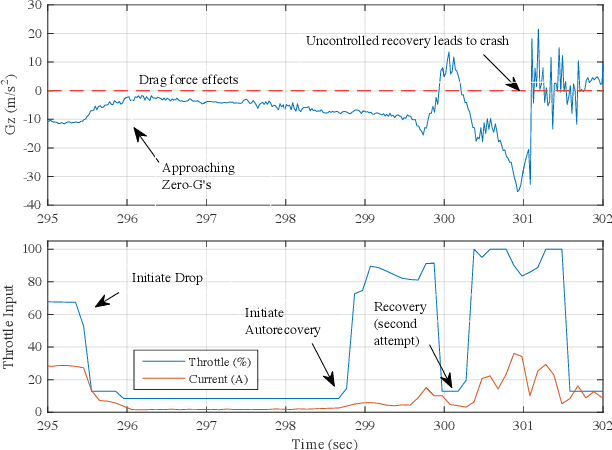

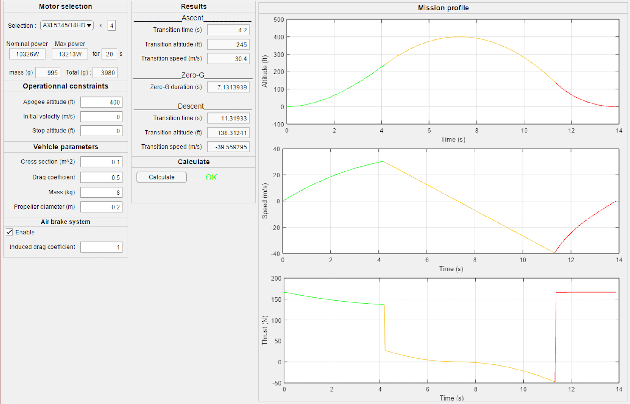

On the Design and Optimization of an Autonomous Microgravity Enabling Aerial Robot

Nov 23, 2016

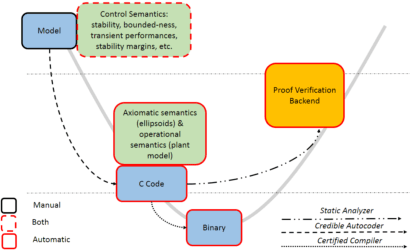

Abstract:This paper describes the process and challenges behind the design and development of a micro-gravity enabling aerial robot. The vehicle, designed to provide at minimum 4 seconds of micro-gravity at an accuracy of .001 g's, is designed with suggestions and constraints from both academia and industry as well a regulatory agency. The feasibility of the flight mission is validated using a simulation environment, where models obtained from system identification of existing hardware are implemented to increase the fidelity of the simulation. The current development of a physical test bed is described. The vehicle employs both control and autonomy logic, which is developed in the Simulink environment and executed in a Pixhawk flight control board.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge