Erik Verreycken

Tool Wear Prediction in CNC Turning Operations using Ultrasonic Microphone Arrays and CNNs

Jun 13, 2024Abstract:This paper introduces a novel method for predicting tool wear in CNC turning operations, combining ultrasonic microphone arrays and convolutional neural networks (CNNs). High-frequency acoustic emissions between 0 kHz and 60 kHz are enhanced using beamforming techniques to improve the signal- to-noise ratio. The processed acoustic data is then analyzed by a CNN, which predicts the Remaining Useful Life (RUL) of cutting tools. Trained on data from 350 workpieces machined with a single carbide insert, the model can accurately predict the RUL of the carbide insert. Our results demonstrate the potential gained by integrating advanced ultrasonic sensors with deep learning for accurate predictive maintenance tasks in CNC machining.

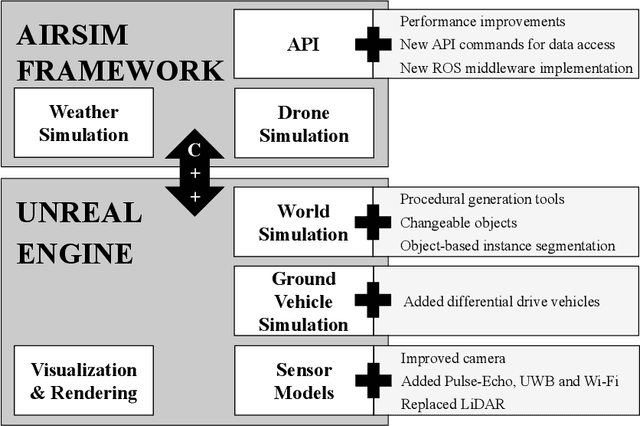

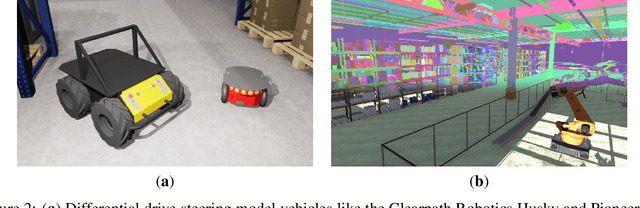

Cosys-AirSim: A Real-Time Simulation Framework Expanded for Complex Industrial Applications

Mar 28, 2023

Abstract:Within academia and industry, there has been a need for expansive simulation frameworks that include model-based simulation of sensors, mobile vehicles, and the environment around them. To this end, the modular, real-time, and open-source AirSim framework has been a popular community-built system that fulfills some of those needs. However, the framework required adding systems to serve some complex industrial applications, including designing and testing new sensor modalities, Simultaneous Localization And Mapping (SLAM), autonomous navigation algorithms, and transfer learning with machine learning models. In this work, we discuss the modification and additions to our open-source version of the AirSim simulation framework, including new sensor modalities, vehicle types, and methods to generate realistic environments with changeable objects procedurally. Furthermore, we show the various applications and use cases the framework can serve.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge