Elena Trajkova

Active Learning and Approximate Model Calibration for Automated Visual Inspection in Manufacturing

Sep 12, 2022

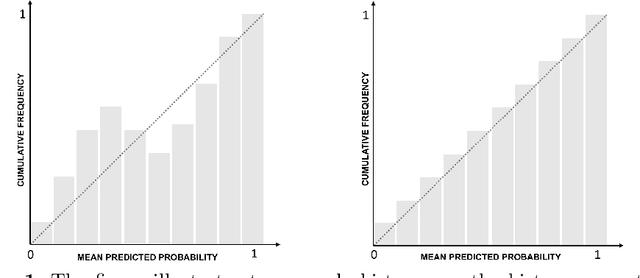

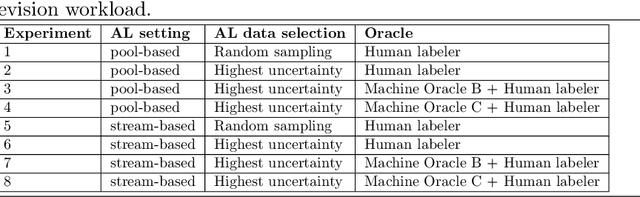

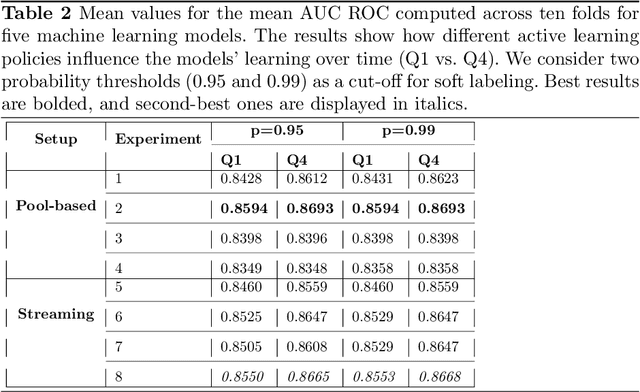

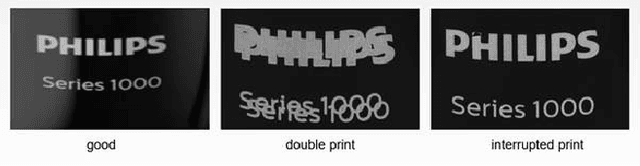

Abstract:Quality control is a crucial activity performed by manufacturing enterprises to ensure that their products meet quality standards and avoid potential damage to the brand's reputation. The decreased cost of sensors and connectivity enabled increasing digitalization of manufacturing. In addition, artificial intelligence enables higher degrees of automation, reducing overall costs and time required for defect inspection. This research compares three active learning approaches (with single and multiple oracles) to visual inspection. We propose a novel approach to probabilities calibration of classification models and two new metrics to assess the performance of the calibration without the need for ground truth. We performed experiments on real-world data provided by Philips Consumer Lifestyle BV. Our results show that explored active learning settings can reduce the data labeling effort by between three and four percent without detriment to the overall quality goals, considering a threshold of p=0.95. Furthermore, we show that the proposed metrics successfully capture relevant information otherwise available to metrics used up to date only through ground truth data. Therefore, the proposed metrics can be used to estimate the quality of models' probability calibration without committing to a labeling effort to obtain ground truth data.

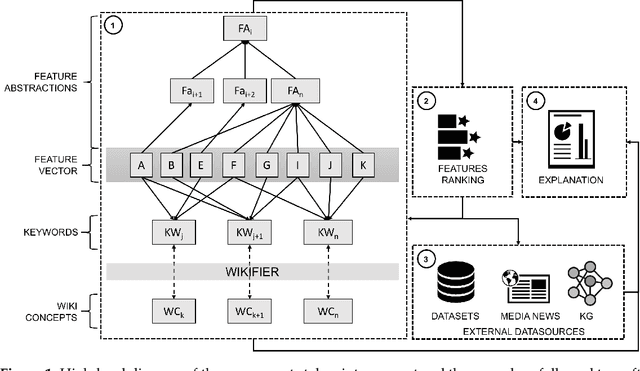

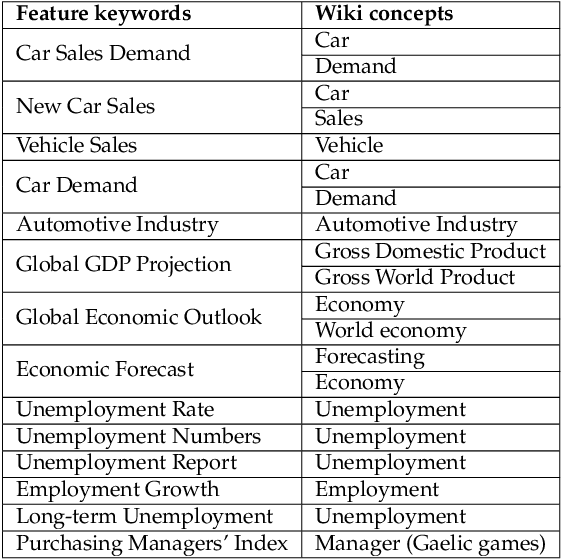

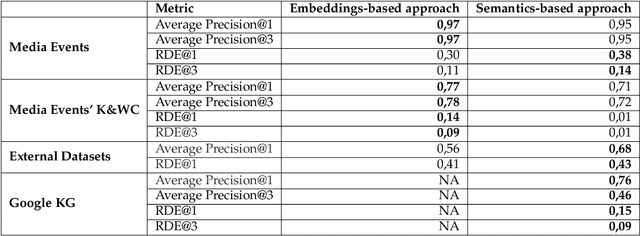

Enriching Artificial Intelligence Explanations with Knowledge Fragments

Apr 12, 2022

Abstract:Artificial Intelligence models are increasingly used in manufacturing to inform decision-making. Responsible decision-making requires accurate forecasts and an understanding of the models' behavior. Furthermore, the insights into models' rationale can be enriched with domain knowledge. This research builds explanations considering feature rankings for a particular forecast, enriching them with media news entries, datasets' metadata, and entries from the Google Knowledge Graph. We compare two approaches (embeddings-based and semantic-based) on a real-world use case regarding demand forecasting.

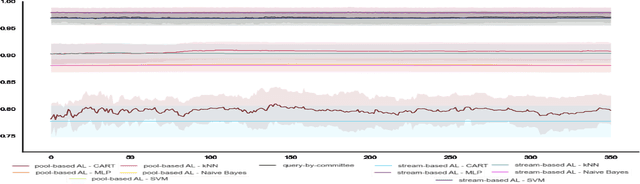

Streaming Machine Learning and Online Active Learning for Automated Visual Inspection

Oct 15, 2021

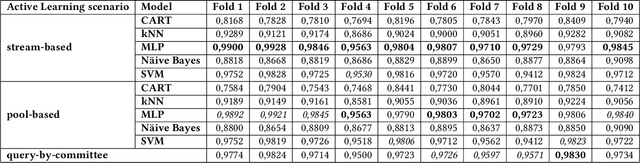

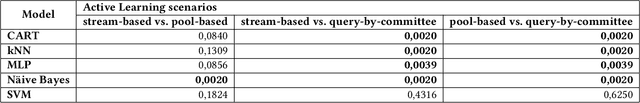

Abstract:Quality control is a key activity performed by manufacturing companies to verify product conformance to the requirements and specifications. Standardized quality control ensures that all the products are evaluated under the same criteria. The decreased cost of sensors and connectivity enabled an increasing digitalization of manufacturing and provided greater data availability. Such data availability has spurred the development of artificial intelligence models, which allow higher degrees of automation and reduced bias when inspecting the products. Furthermore, the increased speed of inspection reduces overall costs and time required for defect inspection. In this research, we compare five streaming machine learning algorithms applied to visual defect inspection with real-world data provided by Philips Consumer Lifestyle BV. Furthermore, we compare them in a streaming active learning context, which reduces the data labeling effort in a real-world context. Our results show that active learning reduces the data labeling effort by almost 15% on average for the worst case, while keeping an acceptable classification performance. The use of machine learning models for automated visual inspection are expected to speed up the quality inspection up to 40%.

Active Learning for Automated Visual Inspection of Manufactured Products

Sep 06, 2021

Abstract:Quality control is a key activity performed by manufacturing enterprises to ensure products meet quality standards and avoid potential damage to the brand's reputation. The decreased cost of sensors and connectivity enabled an increasing digitalization of manufacturing. In addition, artificial intelligence enables higher degrees of automation, reducing overall costs and time required for defect inspection. In this research, we compare three active learning approaches and five machine learning algorithms applied to visual defect inspection with real-world data provided by Philips Consumer Lifestyle BV. Our results show that active learning reduces the data labeling effort without detriment to the models' performance.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge