Bryan Keating

Data Driven Chiller Plant Energy Optimization with Domain Knowledge

Dec 03, 2018

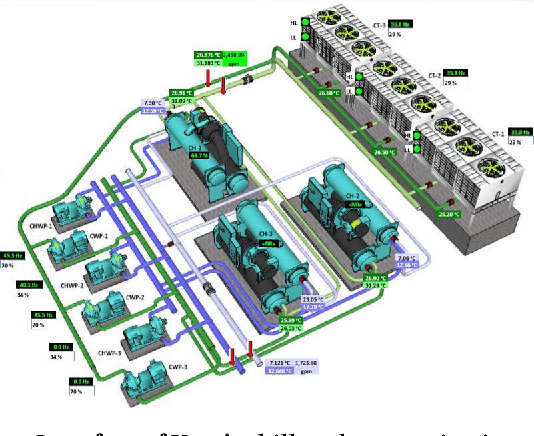

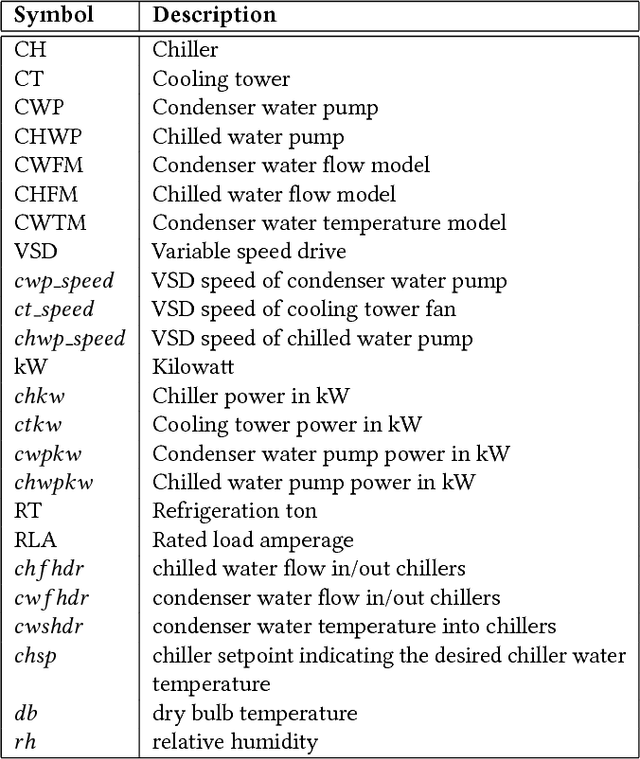

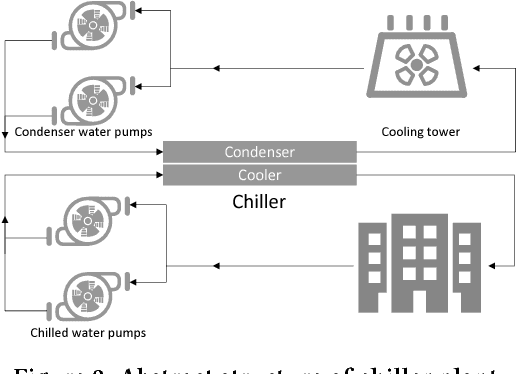

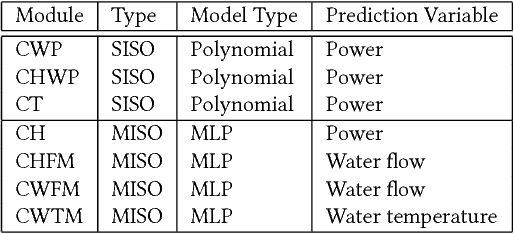

Abstract:Refrigeration and chiller optimization is an important and well studied topic in mechanical engineering, mostly taking advantage of physical models, designed on top of over-simplified assumptions, over the equipments. Conventional optimization techniques using physical models make decisions of online parameter tuning, based on very limited information of hardware specifications and external conditions, e.g., outdoor weather. In recent years, new generation of sensors is becoming essential part of new chiller plants, for the first time allowing the system administrators to continuously monitor the running status of all equipments in a timely and accurate way. The explosive growth of data flowing to databases, driven by the increasing analytical power by machine learning and data mining, unveils new possibilities of data-driven approaches for real-time chiller plant optimization. This paper presents our research and industrial experience on the adoption of data models and optimizations on chiller plant and discusses the lessons learnt from our practice on real world plants. Instead of employing complex machine learning models, we emphasize the incorporation of appropriate domain knowledge into data analysis tools, which turns out to be the key performance improver over state-of-the-art deep learning techniques by a significant margin. Our empirical evaluation on a real world chiller plant achieves savings by more than 7% on daily power consumption.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge