Bo Nørregaard Jørgensen

DataPro -- A Standardized Data Understanding and Processing Procedure: A Case Study of an Eco-Driving Project

Jan 21, 2025Abstract:A systematic pipeline for data processing and knowledge discovery is essential to extracting knowledge from big data and making recommendations for operational decision-making. The CRISP-DM model is the de-facto standard for developing data-mining projects in practice. However, advancements in data processing technologies require enhancements to this framework. This paper presents the DataPro (a standardized data understanding and processing procedure) model, which extends CRISP-DM and emphasizes the link between data scientists and stakeholders by adding the "technical understanding" and "implementation" phases. Firstly, the "technical understanding" phase aligns business demands with technical requirements, ensuring the technical team's accurate comprehension of business goals. Next, the "implementation" phase focuses on the practical application of developed data science models, ensuring theoretical models are effectively applied in business contexts. Furthermore, clearly defining roles and responsibilities in each phase enhances management and communication among all participants. Afterward, a case study on an eco-driving data science project for fuel efficiency analysis in the Danish public transportation sector illustrates the application of the DataPro model. By following the proposed framework, the project identified key business objectives, translated them into technical requirements, and developed models that provided actionable insights for reducing fuel consumption. Finally, the model is evaluated qualitatively, demonstrating its superiority over other data science procedures.

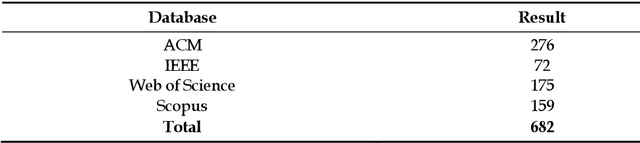

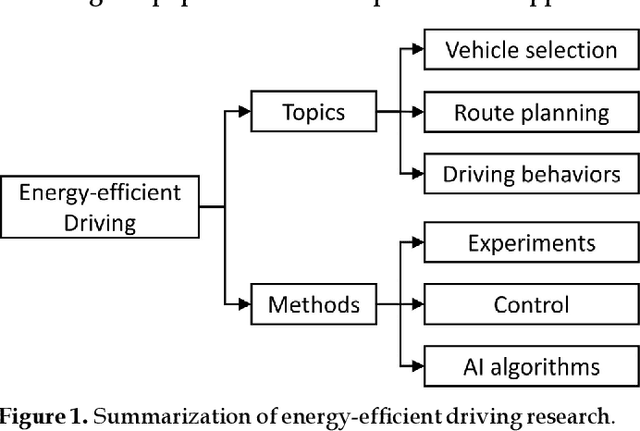

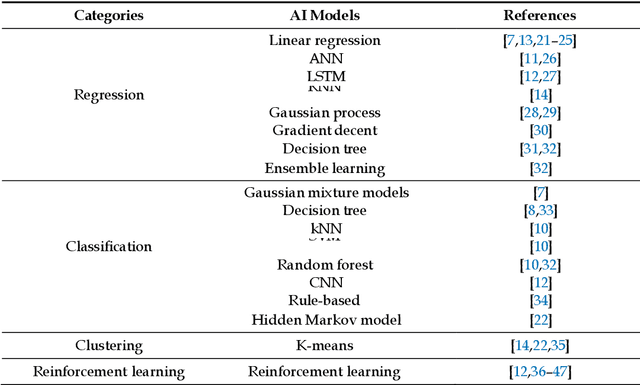

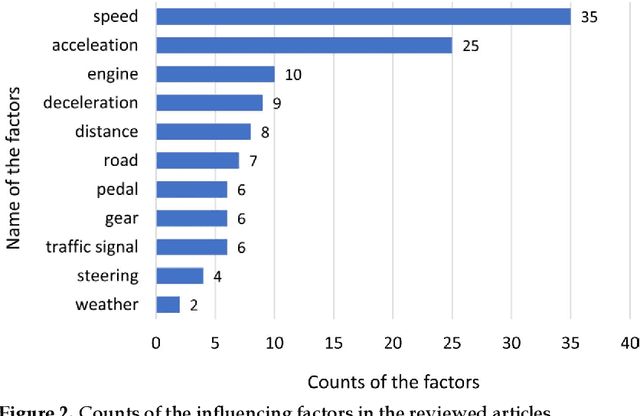

A Scoping Review of Energy-Efficient Driving Behaviors and Applied State-of-the-Art AI Methods

Mar 04, 2024

Abstract:The transportation sector remains a major contributor to greenhouse gas emissions. The understanding of energy-efficient driving behaviors and utilization of energy-efficient driving strategies are essential to reduce vehicles' fuel consumption. However, there is no comprehensive investigation into energy-efficient driving behaviors and strategies. Furthermore, many state-of-the-art AI models have been applied for the analysis of eco-friendly driving styles, but no overview is available. To fill the gap, this paper conducts a thorough literature review on ecological driving behaviors and styles and analyzes the driving factors influencing energy consumption and state-of-the-art methodologies. With a thorough scoping review process, the methodological and related data are compared. The results show that the factors that impact driving behaviors can be summarized into eleven features including speed, acceleration, deceleration, pedal, and so on. This paper finds that supervised/unsupervised learning algorithms and reinforcement learning frameworks have been popularly used to model the vehicle's energy consumption with multi-dimensional data. Furthermore, the literature shows that the driving data are collected from either simulators or real-world experiments, and the real-world data are mainly stored and transmitted by meters, controller area networks, onboard data services, smartphones, and additional sensors installed in the vehicle. Based on driving behavior factors, driver characteristics, and safety rules, this paper recommends nine energy-efficient driving styles including four guidelines for the drivers' selection and adjustment of the vehicle parameters, three recommendations for the energy-efficient driving styles in different driving scenarios, and two subjective suggestions for different types of drivers and employers.

A Novel Hybrid Feature Importance and Feature Interaction Detection Framework for Predictive Optimization in Industry 4.0 Applications

Mar 04, 2024Abstract:Advanced machine learning algorithms are increasingly utilized to provide data-based prediction and decision-making support in Industry 4.0. However, the prediction accuracy achieved by the existing models is insufficient to warrant practical implementation in real-world applications. This is because not all features present in real-world datasets possess a direct relevance to the predictive analysis being conducted. Consequently, the careful incorporation of select features has the potential to yield a substantial positive impact on the outcome. To address the research gap, this paper proposes a novel hybrid framework that combines the feature importance detector - local interpretable model-agnostic explanations (LIME) and the feature interaction detector - neural interaction detection (NID), to improve prediction accuracy. By applying the proposed framework, unnecessary features can be eliminated, and interactions are encoded to generate a more conducive dataset for predictive purposes. Subsequently, the proposed model is deployed to refine the prediction of electricity consumption in foundry processing. The experimental outcomes reveal an augmentation of up to 9.56% in the R2 score, and a diminution of up to 24.05% in the root mean square error.

Identifying Best Practice Melting Patterns in Induction Furnaces: A Data-Driven Approach Using Time Series KMeans Clustering and Multi-Criteria Decision Making

Jan 09, 2024Abstract:Improving energy efficiency in industrial production processes is crucial for competitiveness, and compliance with climate policies. This paper introduces a data-driven approach to identify optimal melting patterns in induction furnaces. Through time-series K-means clustering the melting patterns could be classified into distinct clusters based on temperature profiles. Using the elbow method, 12 clusters were identified, representing the range of melting patterns. Performance parameters such as melting time, energy-specific performance, and carbon cost were established for each cluster, indicating furnace efficiency and environmental impact. Multiple criteria decision-making methods including Simple Additive Weighting, Multiplicative Exponential Weighting, Technique for Order of Preference by Similarity to Ideal Solution, modified TOPSIS, and VlseKriterijumska Optimizacija I Kompromisno Resenje were utilized to determine the best-practice cluster. The study successfully identified the cluster with the best performance. Implementing the best practice operation resulted in an 8.6 % reduction in electricity costs, highlighting the potential energy savings in the foundry.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge