Ayush Mohanty

Federated Granger Causality Learning for Interdependent Clients with State Space Representation

Jan 27, 2025

Abstract:Advanced sensors and IoT devices have improved the monitoring and control of complex industrial enterprises. They have also created an interdependent fabric of geographically distributed process operations (clients) across these enterprises. Granger causality is an effective approach to detect and quantify interdependencies by examining how one client's state affects others over time. Understanding these interdependencies captures how localized events, such as faults and disruptions, can propagate throughout the system, possibly causing widespread operational impacts. However, the large volume and complexity of industrial data pose challenges in modeling these interdependencies. This paper develops a federated approach to learning Granger causality. We utilize a linear state space system framework that leverages low-dimensional state estimates to analyze interdependencies. This addresses bandwidth limitations and the computational burden commonly associated with centralized data processing. We propose augmenting the client models with the Granger causality information learned by the server through a Machine Learning (ML) function. We examine the co-dependence between the augmented client and server models and reformulate the framework as a standalone ML algorithm providing conditions for its sublinear and linear convergence rates. We also study the convergence of the framework to a centralized oracle model. Moreover, we include a differential privacy analysis to ensure data security while preserving causal insights. Using synthetic data, we conduct comprehensive experiments to demonstrate the robustness of our approach to perturbations in causality, the scalability to the size of communication, number of clients, and the dimensions of raw data. We also evaluate the performance on two real-world industrial control system datasets by reporting the volume of data saved by decentralization.

Prognostic Framework for Robotic Manipulators Operating Under Dynamic Task Severities

Nov 30, 2024

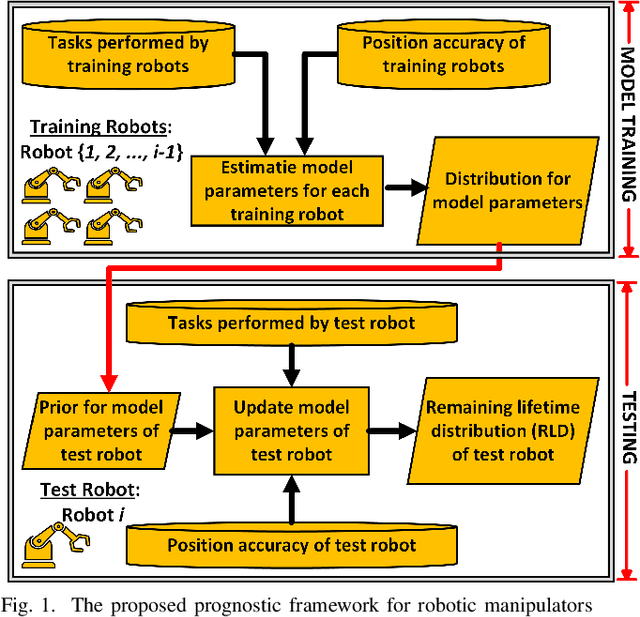

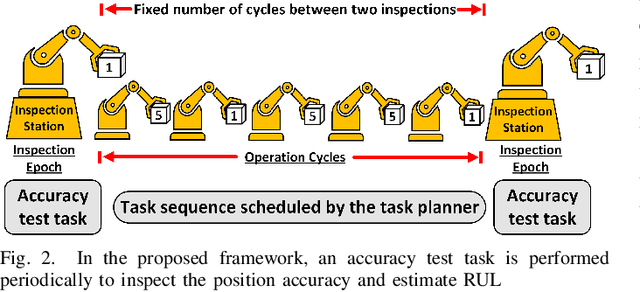

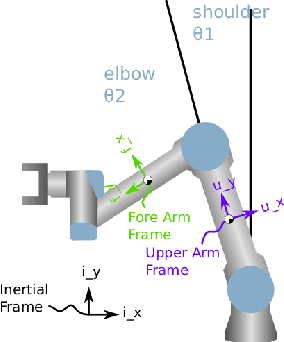

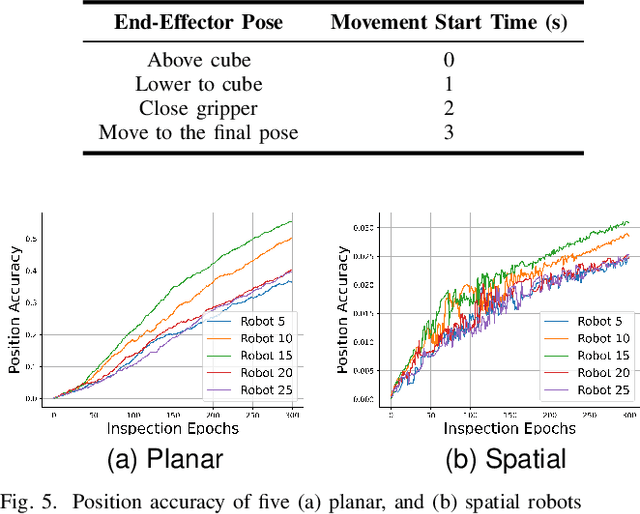

Abstract:Robotic manipulators are critical in many applications but are known to degrade over time. This degradation is influenced by the nature of the tasks performed by the robot. Tasks with higher severity, such as handling heavy payloads, can accelerate the degradation process. One way this degradation is reflected is in the position accuracy of the robot's end-effector. In this paper, we present a prognostic modeling framework that predicts a robotic manipulator's Remaining Useful Life (RUL) while accounting for the effects of task severity. Our framework represents the robot's position accuracy as a Brownian motion process with a random drift parameter that is influenced by task severity. The dynamic nature of task severity is modeled using a continuous-time Markov chain (CTMC). To evaluate RUL, we discuss two approaches -- (1) a novel closed-form expression for Remaining Lifetime Distribution (RLD), and (2) Monte Carlo simulations, commonly used in prognostics literature. Theoretical results establish the equivalence between these RUL computation approaches. We validate our framework through experiments using two distinct physics-based simulators for planar and spatial robot fleets. Our findings show that robots in both fleets experience shorter RUL when handling a higher proportion of high-severity tasks.

Sensor-fusion based Prognostics Framework for Complex Engineering Systems Exhibiting Multiple Failure Modes

Nov 19, 2024Abstract:Complex engineering systems are often subject to multiple failure modes. Developing a remaining useful life (RUL) prediction model that does not consider the failure mode causing degradation is likely to result in inaccurate predictions. However, distinguishing between causes of failure without manually inspecting the system is nontrivial. This challenge is increased when the causes of historically observed failures are unknown. Sensors, which are useful for monitoring the state-of-health of systems, can also be used for distinguishing between multiple failure modes as the presence of multiple failure modes results in discriminatory behavior of the sensor signals. When systems are equipped with multiple sensors, some sensors may exhibit behavior correlated with degradation, while other sensors do not. Furthermore, which sensors exhibit this behavior may differ for each failure mode. In this paper, we present a simultaneous clustering and sensor selection approach for unlabeled training datasets of systems exhibiting multiple failure modes. The cluster assignments and the selected sensors are then utilized in real-time to first diagnose the active failure mode and then to predict the system RUL. We validate the complete pipeline of the methodology using a simulated dataset of systems exhibiting two failure modes and on a turbofan degradation dataset from NASA.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge