Amir Dahari

Prediction of microstructural representativity from a single image

Oct 25, 2024

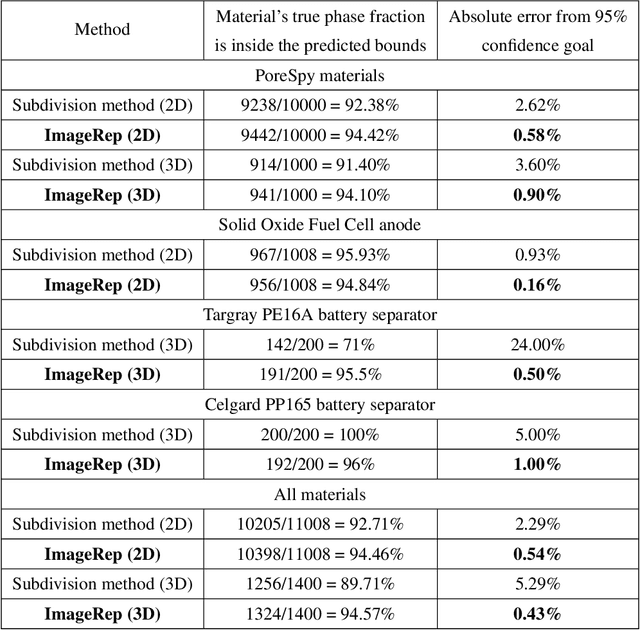

Abstract:In this study, we present a method for predicting the representativity of the phase fraction observed in a single image (2D or 3D) of a material. Traditional approaches often require large datasets and extensive statistical analysis to estimate the Integral Range, a key factor in determining the variance of microstructural properties. Our method leverages the Two-Point Correlation function to directly estimate the variance from a single image (2D or 3D), thereby enabling phase fraction prediction with associated confidence levels. We validate our approach using open-source datasets, demonstrating its efficacy across diverse microstructures. This technique significantly reduces the data requirements for representativity analysis, providing a practical tool for material scientists and engineers working with limited microstructural data. To make the method easily accessible, we have created a web-application, \url{www.imagerep.io}, for quick, simple and informative use of the method.

Two approaches to inpainting microstructure with deep convolutional generative adversarial networks

Oct 13, 2022

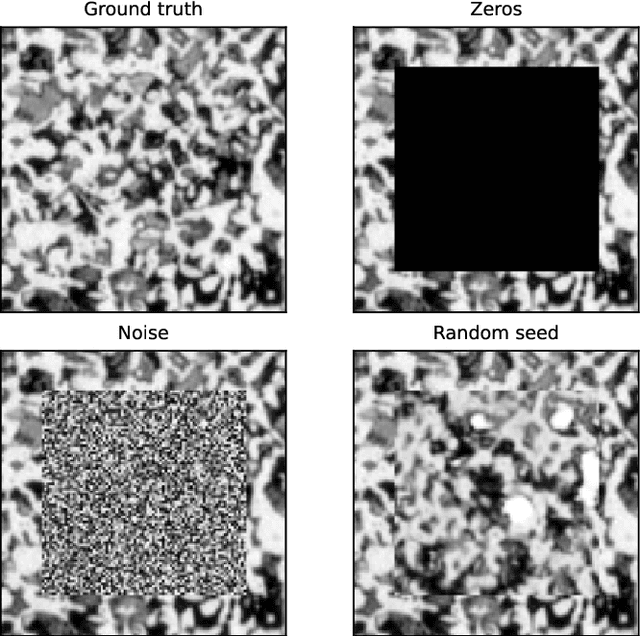

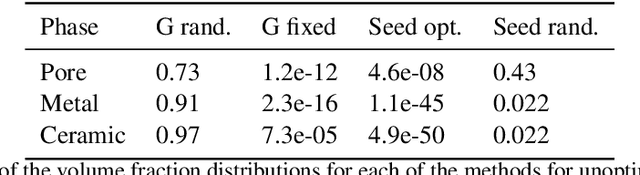

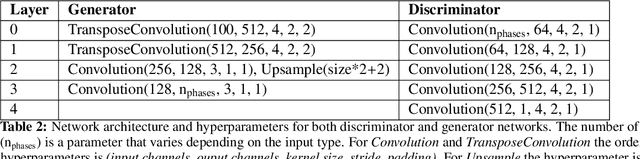

Abstract:Imaging is critical to the characterisation of materials. However, even with careful sample preparation and microscope calibration, imaging techniques are often prone to defects and unwanted artefacts. This is particularly problematic for applications where the micrograph is to be used for simulation or feature analysis, as defects are likely to lead to inaccurate results. Microstructural inpainting is a method to alleviate this problem by replacing occluded regions with synthetic microstructure with matching boundaries. In this paper we introduce two methods that use generative adversarial networks to generate contiguous inpainted regions of arbitrary shape and size by learning the microstructural distribution from the unoccluded data. We find that one benefits from high speed and simplicity, whilst the other gives smoother boundaries at the inpainting border. We also outline the development of a graphical user interface that allows users to utilise these machine learning methods in a 'no-code' environment.

MicroLib: A library of 3D microstructures generated from 2D micrographs using SliceGAN

Oct 12, 2022

Abstract:3D microstructural datasets are commonly used to define the geometrical domains used in finite element modelling. This has proven a useful tool for understanding how complex material systems behave under applied stresses, temperatures and chemical conditions. However, 3D imaging of materials is challenging for a number of reasons, including limited field of view, low resolution and difficult sample preparation. Recently, a machine learning method, SliceGAN, was developed to statistically generate 3D microstructural datasets of arbitrary size using a single 2D input slice as training data. In this paper, we present the results from applying SliceGAN to 87 different microstructures, ranging from biological materials to high-strength steels. To demonstrate the accuracy of the synthetic volumes created by SliceGAN, we compare three microstructural properties between the 2D training data and 3D generations, which show good agreement. This new microstructure library both provides valuable 3D microstructures that can be used in models, and also demonstrates the broad applicability of the SliceGAN algorithm.

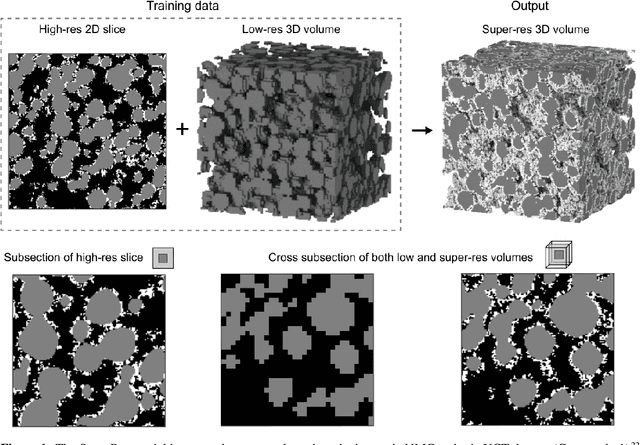

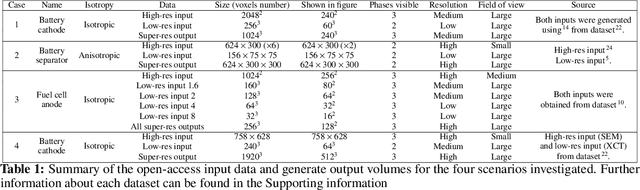

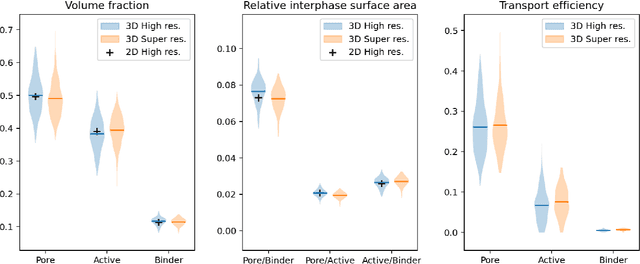

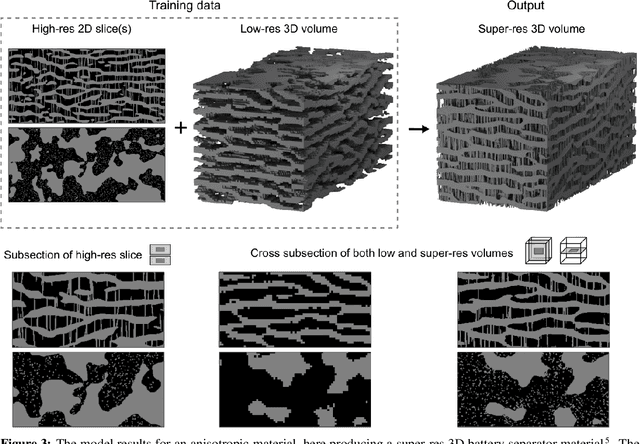

Super-resolution of multiphase materials by combining complementary 2D and 3D image data using generative adversarial networks

Oct 22, 2021

Abstract:Modelling the impact of a material's mesostructure on device level performance typically requires access to 3D image data containing all the relevant information to define the geometry of the simulation domain. This image data must include sufficient contrast between phases to distinguish each material, be of high enough resolution to capture the key details, but also have a large enough field-of-view to be representative of the material in general. It is rarely possible to obtain data with all of these properties from a single imaging technique. In this paper, we present a method for combining information from pairs of distinct but complementary imaging techniques in order to accurately reconstruct the desired multi-phase, high resolution, representative, 3D images. Specifically, we use deep convolutional generative adversarial networks to implement super-resolution, style transfer and dimensionality expansion. To demonstrate the widespread applicability of this tool, two pairs of datasets are used to validate the quality of the volumes generated by fusing the information from paired imaging techniques. Three key mesostructural metrics are calculated in each case to show the accuracy of this method. Having confidence in the accuracy of our method, we then demonstrate its power by applying to a real data pair from a lithium ion battery electrode, where the required 3D high resolution image data is not available anywhere in the literature. We believe this approach is superior to previously reported statistical material reconstruction methods both in terms of its fidelity and ease of use. Furthermore, much of the data required to train this algorithm already exists in the literature, waiting to be combined. As such, our open-access code could precipitate a step change by generating the hard to obtain high quality image volumes necessary to simulate behaviour at the mesoscale.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge