Amin Fakhari

Motion Planning for Object Manipulation by Edge-Rolling

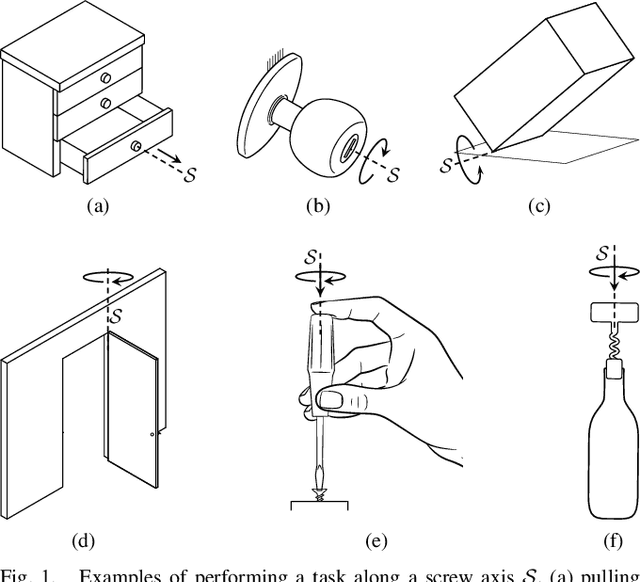

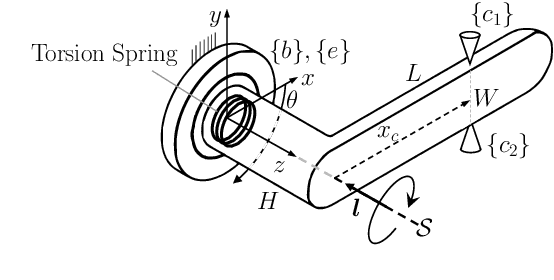

Oct 11, 2024Abstract:A common way to manipulate heavy objects is to maintain at least one point of the object in contact with the environment during the manipulation. When the object has a cylindrical shape or, in general, a curved edge, not only sliding and pivoting motions but also rolling the object along the edge can effectively satisfy this condition. Edge-rolling offers several advantages in terms of efficiency and maneuverability. This paper aims to develop a novel approach for approximating the prehensile edge-rolling motion on any path by a sequence of constant screw displacements, leveraging the principles of screw theory. Based on this approach, we proposed an algorithmic method for task-space-based path generation of object manipulation between two given configurations using a sequence of rolling and pivoting motions. The method is based on an optimization algorithm that takes into account the joint limitations of the robot. To validate our approach, we conducted experiments to manipulate a cylinder along linear and curved paths using the Franka Emika Panda manipulator.

Computing a Task-Dependent Grasp Metric Using Second Order Cone Programs

Apr 25, 2021

Abstract:Evaluating a grasp generated by a set of hand-object contact locations is a key component of many grasp planning algorithms. In this paper, we present a novel second order cone program (SOCP) based optimization formulation for evaluating a grasps' ability to apply wrenches to generate a linear motion along a given direction and/or an angular motion about the given direction. Our quality measure can be computed efficiently, since the SOCP is a convex optimization problem, which can be solved optimally with interior point methods. A key feature of our approach is that we can consider the effect of contact wrenches from any contact of the object with the environment. This is different from the extant literature where only the effect of finger-object contacts is considered. Exploiting the environmental contact is useful in many manipulation scenarios either to enhance the dexterity of simple hands or improve the payload capability of the manipulator. In contrast to most existing approaches, our approach also takes into account the practical constraint that the maximum contact force that can be applied at a finger-object contact can be different for each contact. We can also include the effect of external forces like gravity, as well as the joint torque constraints of the fingers/manipulators. Furthermore, for a given motion path as a constant screw motion or a sequence of constant screw motions, we can discretize the path and compute a global grasp metric to accomplish the whole task with a chosen set of finger-object contact locations.

Motion and Force Planning for Manipulating Heavy Objects by Pivoting

Dec 10, 2020

Abstract:Manipulation of objects by exploiting their contact with the environment can enhance both the dexterity and payload capability of robotic manipulators. A common way to manipulate heavy objects beyond the payload capability of a robot is to use a sequence of pivoting motions, wherein, an object is moved while some contact points between the object and a support surface are kept fixed. The goal of this paper is to develop an algorithmic approach for automated plan generation for object manipulation with a sequence of pivoting motions. A plan for manipulating a heavy object consists of a sequence of joint angles of the manipulator, the corresponding object poses, as well as the joint torques required to move the object. The constraint of maintaining object contact with the ground during manipulation results in nonlinear constraints in the configuration space of the robot, which is challenging for motion planning algorithms. Exploiting the fact that pivoting motion corresponds to movements in a subgroup of the group of rigid body motions, SE(3), we present a novel task-space based planning approach for computing a motion plan for both the manipulator and the object while satisfying contact constraints. We also combine our motion planning algorithm with a grasping force synthesis algorithm to ensure that friction constraints at the contacts and actuator torque constraints are satisfied. We present simulation results with a dual-armed Baxter robot to demonstrate our approach.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge