Warranty Cost Estimation Using Bayesian Network

Paper and Code

Nov 11, 2014

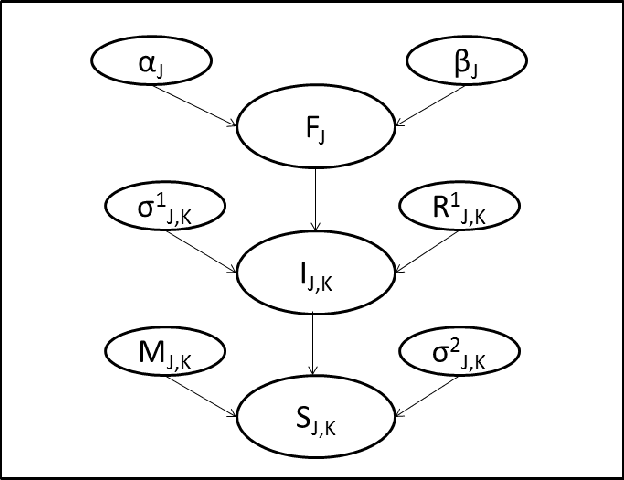

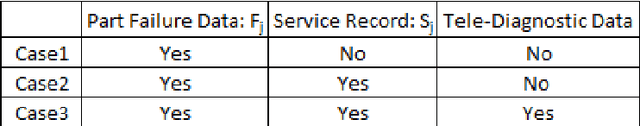

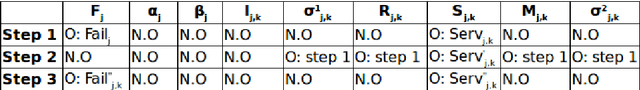

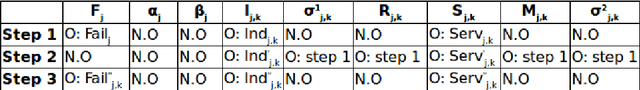

All multi-component product manufacturing companies face the problem of warranty cost estimation. Failure rate analysis of components plays a key role in this problem. Data source used for failure rate analysis has traditionally been past failure data of components. However, failure rate analysis can be improved by means of fusion of additional information, such as symptoms observed during after-sale service of the product, geographical information (hilly or plains areas), and information from tele-diagnostic analytics. In this paper, we propose an approach, which learns dependency between part-failures and symptoms gleaned from such diverse sources of information, to predict expected number of failures with better accuracy. We also indicate how the optimum warranty period can be computed. We demonstrate, through empirical results, that our method can improve the warranty cost estimates significantly.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge