Two-Stage Deep Anomaly Detection with Heterogeneous Time Series Data

Paper and Code

Feb 10, 2022

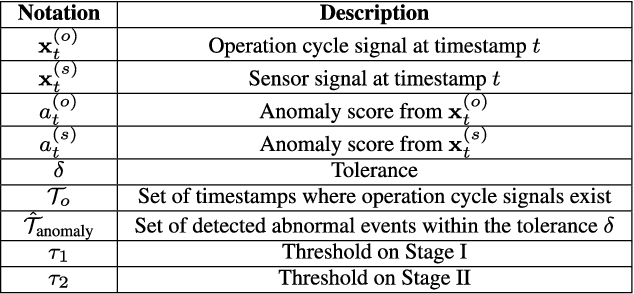

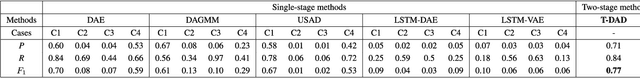

We introduce a data-driven anomaly detection framework using a manufacturing dataset collected from a factory assembly line. Given heterogeneous time series data consisting of operation cycle signals and sensor signals, we aim at discovering abnormal events. Motivated by our empirical findings that conventional single-stage benchmark approaches may not exhibit satisfactory performance under our challenging circumstances, we propose a two-stage deep anomaly detection (TDAD) framework in which two different unsupervised learning models are adopted depending on types of signals. In Stage I, we select anomaly candidates by using a model trained by operation cycle signals; in Stage II, we finally detect abnormal events out of the candidates by using another model, which is suitable for taking advantage of temporal continuity, trained by sensor signals. A distinguishable feature of our framework is that operation cycle signals are exploited first to find likely anomalous points, whereas sensor signals are leveraged to filter out unlikely anomalous points afterward. Our experiments comprehensively demonstrate the superiority over single-stage benchmark approaches, the model-agnostic property, and the robustness to difficult situations.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge