Toward Process Controlled Medical Robotic System

Paper and Code

Aug 10, 2023

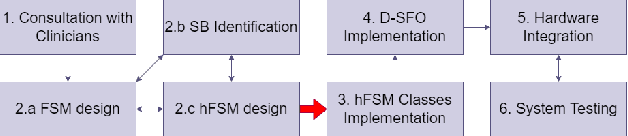

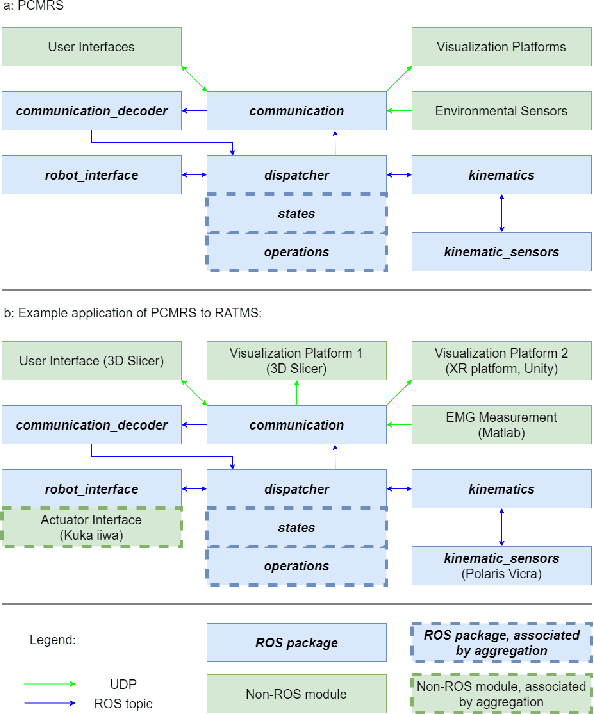

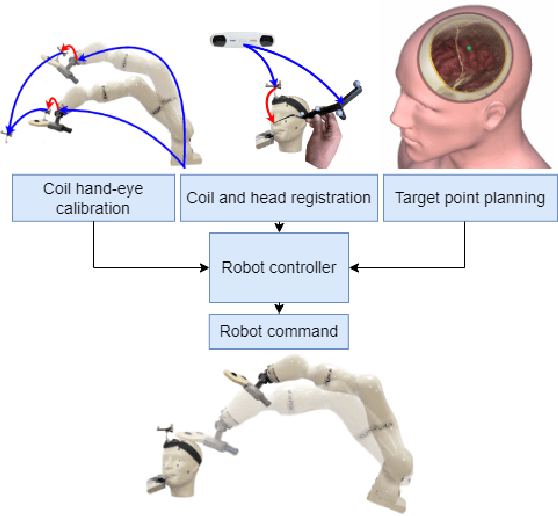

Medical errors, defined as unintended acts either of omission or commission that cause the failure of medical actions, are the third leading cause of death in the United States. The application of autonomy and robotics can alleviate some causes of medical errors by improving accuracy and providing means to preciously follow planned procedures. However, for the robotic applications to improve safety, they must maintain constant operating conditions in the presence of disturbances, and provide reliable measurements, evaluation, and control for each state of the procedure. This article addresses the need for process control in medical robotic systems, and proposes a standardized design cycle toward its automation. Monitoring and controlling the changing conditions in a medical or surgical environment necessitates a clear definition of workflows and their procedural dependencies. We propose integrating process control into medical robotic workflows to identify change in states of the system and environment, possible operations, and transitions to new states. Therefore, the system translates clinician experiences and procedure workflows into machine-interpretable languages. The design cycle using hFSM formulation can be a deterministic process, which opens up possibilities for higher-level automation in medical robotics. Shown in our work, with a standardized design cycle and software paradigm, we pave the way toward controlled workflows that can be automatically generated. Additionally, a modular design for a robotic system architecture that integrates hFSM can provide easy software and hardware integration. This article discusses the system design, software implementation, and example application to Robot-Assisted Transcranial Magnetic Stimulation and robot-assisted femoroplasty. We also provide assessments of these two system examples by testing their robotic tool placement.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge