Temporal data mining for root-cause analysis of machine faults in automotive assembly lines

Paper and Code

Apr 30, 2009

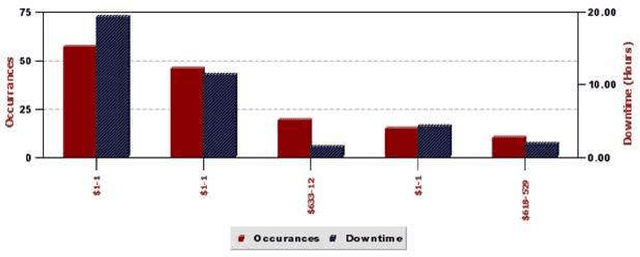

Engine assembly is a complex and heavily automated distributed-control process, with large amounts of faults data logged everyday. We describe an application of temporal data mining for analyzing fault logs in an engine assembly plant. Frequent episode discovery framework is a model-free method that can be used to deduce (temporal) correlations among events from the logs in an efficient manner. In addition to being theoretically elegant and computationally efficient, frequent episodes are also easy to interpret in the form actionable recommendations. Incorporation of domain-specific information is critical to successful application of the method for analyzing fault logs in the manufacturing domain. We show how domain-specific knowledge can be incorporated using heuristic rules that act as pre-filters and post-filters to frequent episode discovery. The system described here is currently being used in one of the engine assembly plants of General Motors and is planned for adaptation in other plants. To the best of our knowledge, this paper presents the first real, large-scale application of temporal data mining in the manufacturing domain. We believe that the ideas presented in this paper can help practitioners engineer tools for analysis in other similar or related application domains as well.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge