Temporal Convolutional Memory Networks for Remaining Useful Life Estimation of Industrial Machinery

Paper and Code

Oct 12, 2018

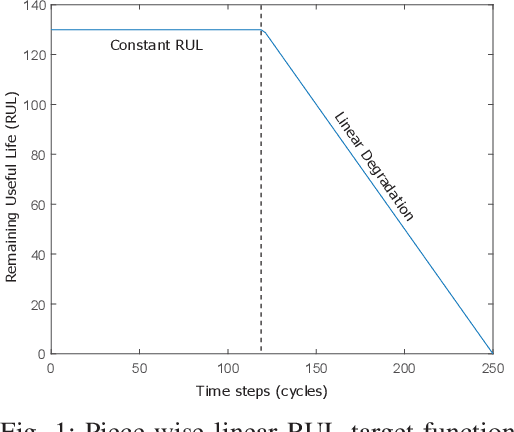

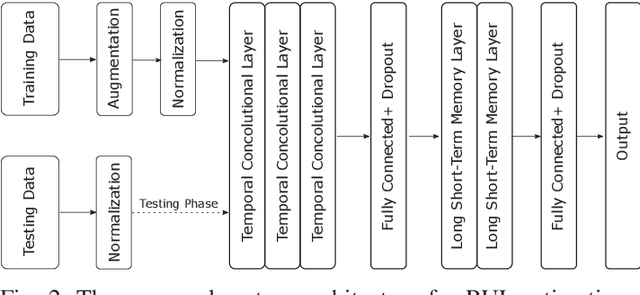

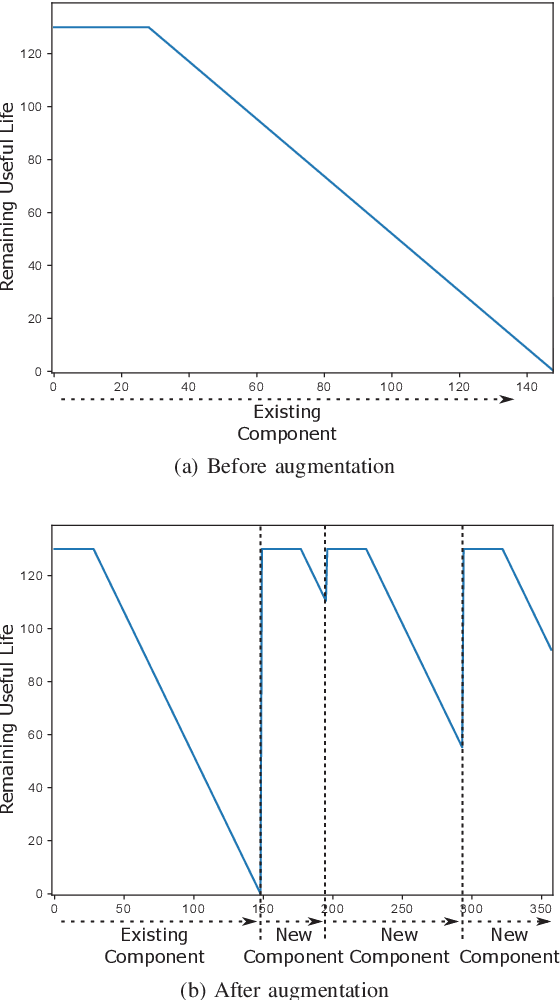

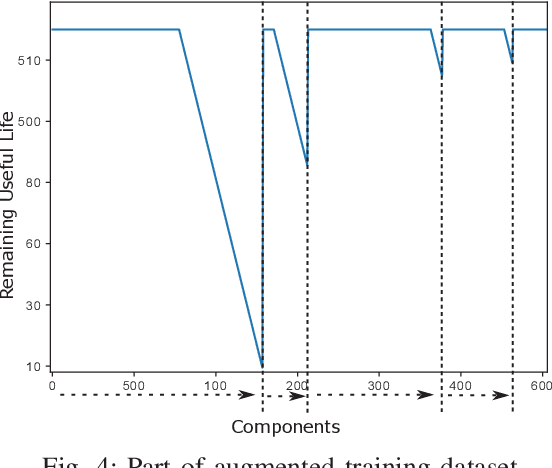

Accurately estimating the remaining useful life (RUL) of industrial machinery is beneficial in many real-world applications. Estimation techniques have mainly utilized linear models or neural network based approaches with a focus on short term time dependencies. This paper introduces a system model that incorporates temporal convolutions with both long term and short term time dependencies. The proposed network learns salient features and complex temporal variations in sensor values, and predicts the RUL. A data augmentation method is used for increased accuracy. The proposed method is compared with several state-of-the-art algorithms on publicly available datasets. It demonstrates promising results, with superior results for datasets obtained from complex environments.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge