Sparse Attention-driven Quality Prediction for Production Process Optimization in Digital Twins

Paper and Code

May 20, 2024

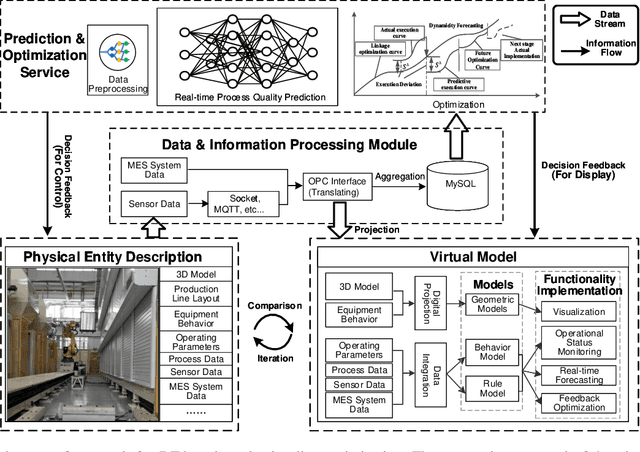

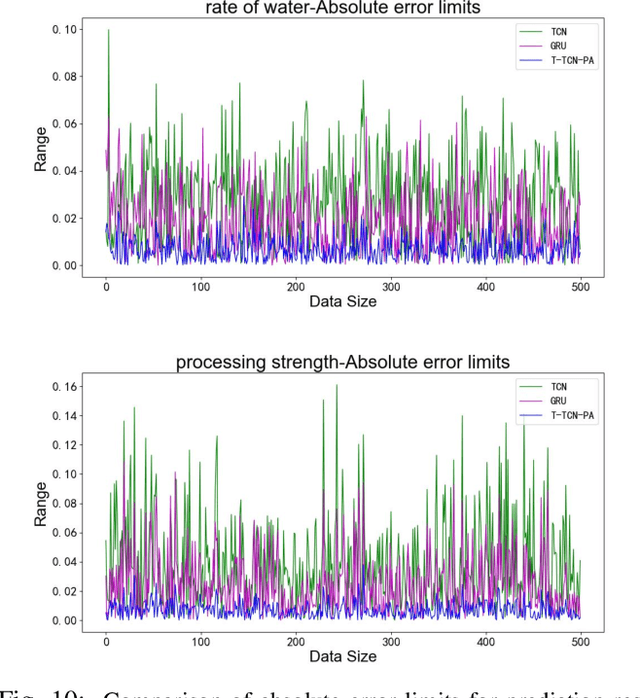

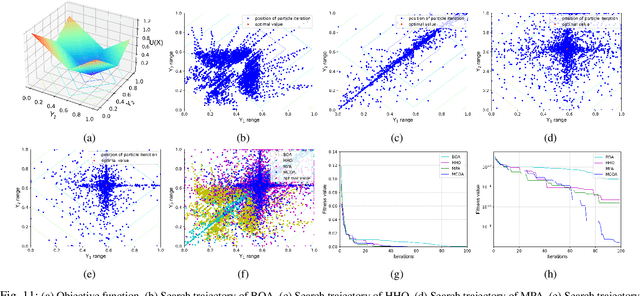

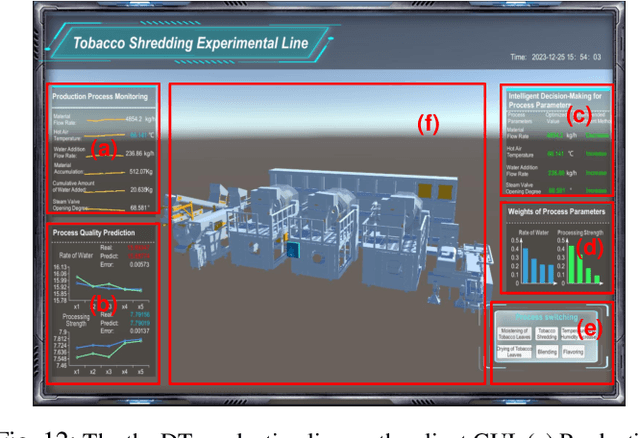

In the process industry, optimizing production lines for long-term efficiency requires real-time monitoring and analysis of operation states to fine-tune production line parameters. However, the complexity in operational logic and the intricate coupling of production process parameters make it difficult to develop an accurate mathematical model for the entire process, thus hindering the deployment of efficient optimization mechanisms. In view of these difficulties, we propose to deploy a digital twin of the production line by digitally abstracting its physical layout and operational logic. By iteratively mapping the real-world data reflecting equipment operation status and product quality inspection in the digital twin, we adopt a quality prediction model for production process based on self-attention-enabled temporal convolutional neural networks. This model enables the data-driven state evolution of the digital twin. The digital twin takes a role of aggregating the information of actual operating conditions and the results of quality-sensitive analysis, which facilitates the optimization of process production quality with virtual-reality evolution under multi-dimensional constraints. Leveraging the digital twin model as an information-flow carrier, we extract temporal features from key process indicators and establish a production process quality prediction model based on the proposed composite neural network. Our operation experiments on a specific tobacco shredding line demonstrate that the proposed digital twin-based production process optimization method fosters seamless integration between virtual and real production lines. This integration achieves an average operating status prediction accuracy of over 98\% and near-optimal production process control.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge