Scalable and Probabilistically Complete Planning for Robotic Spatial Extrusion

Paper and Code

Feb 06, 2020

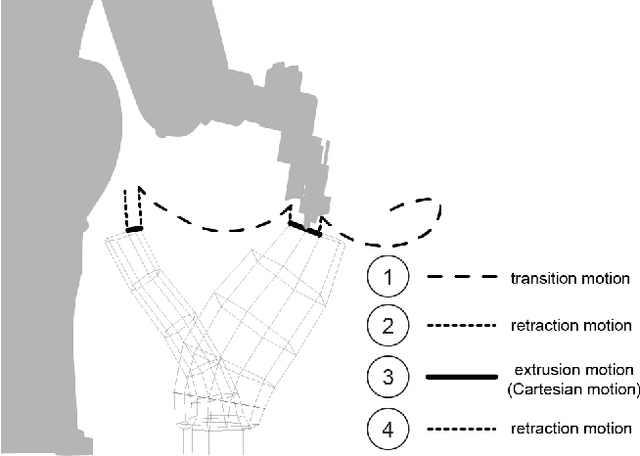

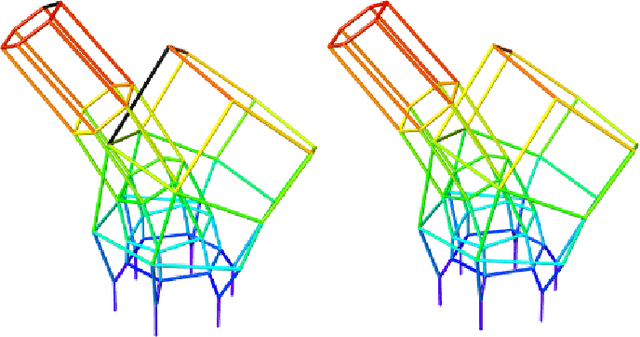

There is increasing demand for automated systems that can fabricate 3D structures. Robotic spatial extrusion has become an attractive alternative to traditional layer-based 3D printing due to a manipulator's flexibility to print large, directionally-dependent structures. However, existing extrusion planning algorithms require a substantial amount of human input, do not scale to large instances, and lack theoretical guarantees. In this work, we present a rigorous formalization of robotic spatial extrusion planning and provide several efficient and probabilistically complete planning algorithms. The key planning challenge is, throughout the printing process, satisfying both stiffness constraints that limit the deformation of the structure and geometric constraints that ensure the robot does not collide with the structure. We show that, although these constraints often conflict with each other, a greedy backward state-space search guided by a stiffness-aware heuristic is able to successfully balance both constraints. We empirically compare our methods on a benchmark of over 40 simulated extrusion problems. Finally, we apply our approach to 3 real-world extrusion problems.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge