Optimizing Container Loading and Unloading through Dual-Cycling and Dockyard Rehandle Reduction Using a Hybrid Genetic Algorithm

Paper and Code

Jun 12, 2024

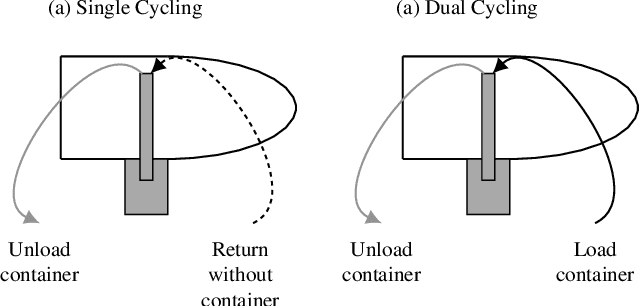

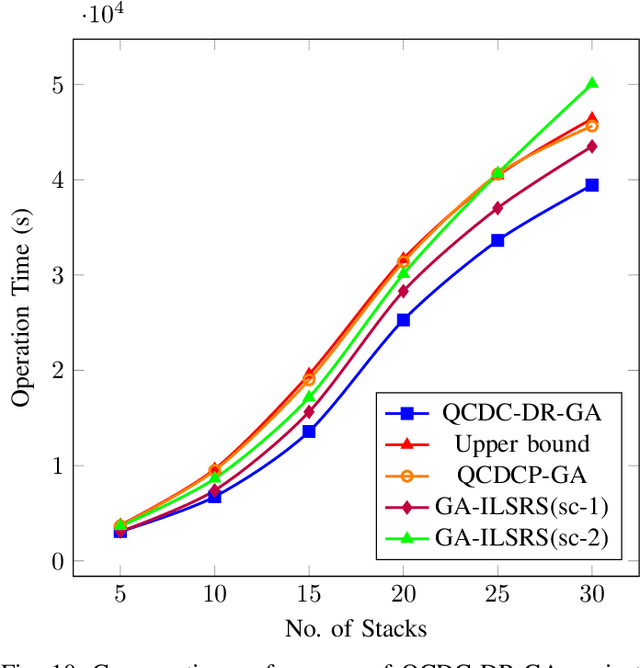

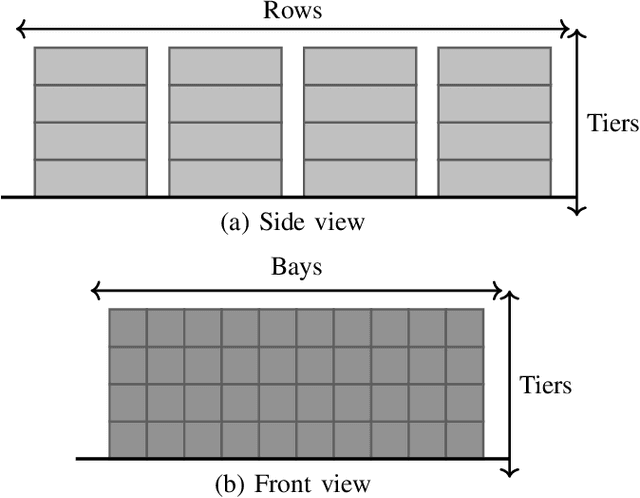

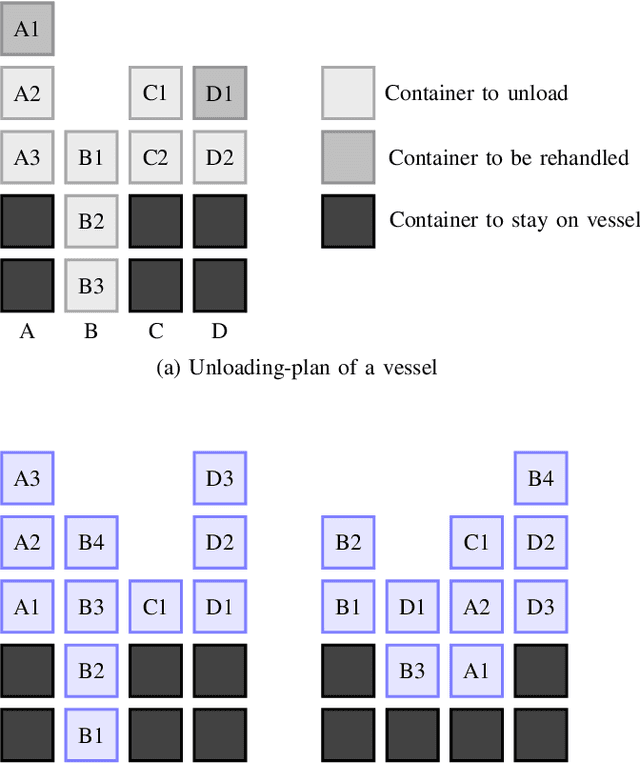

This paper addresses the optimization of container unloading and loading operations at ports, integrating quay-crane dual-cycling with dockyard rehandle minimization. We present a unified model encompassing both operations: ship container unloading and loading by quay crane, and the other is reducing dockyard rehandles while loading the ship. We recognize that optimizing one aspect in isolation can lead to suboptimal outcomes due to interdependencies. Specifically, optimizing unloading sequences for minimal operation time may inadvertently increase dockyard rehandles during loading and vice versa. To address this NP-hard problem, we propose a hybrid genetic algorithm (GA) QCDC-DR-GA comprising one-dimensional and two-dimensional GA components. Our model, QCDC-DR-GA, consistently outperforms four state-of-the-art methods in maximizing dual cycles and minimizing dockyard rehandles. Compared to those methods, it reduced 15-20% of total operation time for large vessels. Statistical validation through a two-tailed paired t-test confirms the superiority of QCDC-DR-GA at a 5% significance level. The approach effectively combines QCDC optimization with dockyard rehandle minimization, optimizing the total unloading-loading time. Results underscore the inefficiency of separately optimizing QCDC and dockyard rehandles. Fragmented approaches, such as QCDC Scheduling Optimized by bi-level GA and GA-ILSRS (Scenario 2), show limited improvement compared to QCDC-DR-GA. As in GA-ILSRS (Scenario 1), neglecting dual-cycle optimization leads to inferior performance than QCDC-DR-GA. This emphasizes the necessity of simultaneously considering both aspects for optimal resource utilization and overall operational efficiency.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge