Mobile 3D Printing Robot Simulation with Viscoelastic Fluids

Paper and Code

Oct 08, 2021

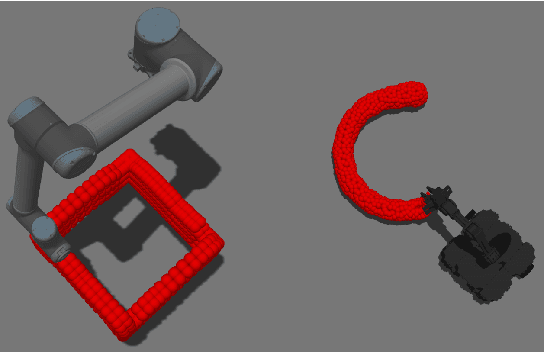

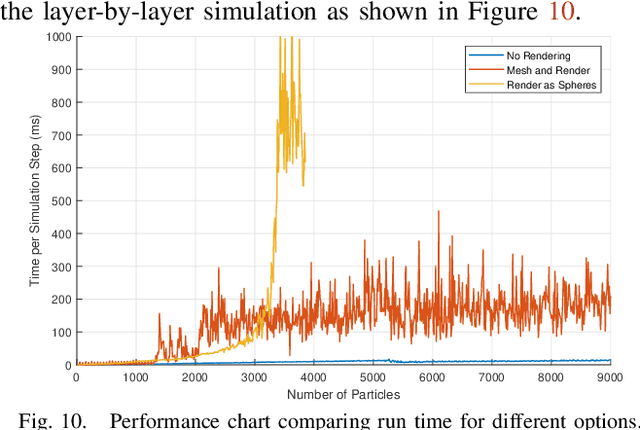

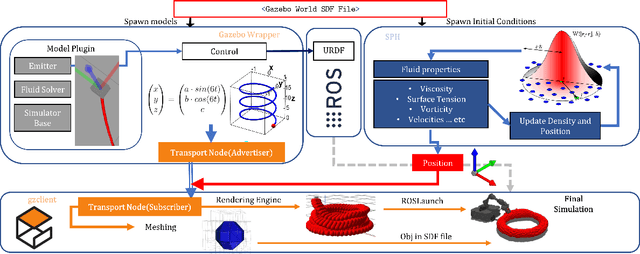

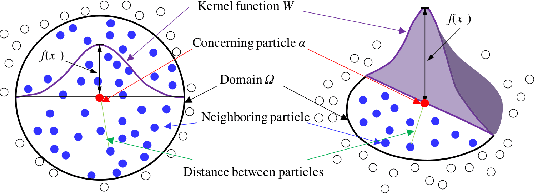

The system design and algorithm development of mobile 3D printing robots need a realistic simulation. They require a mobile robot simulation platform to interoperate with a physics-based material simulation for handling interactions between the time-variant deformable 3D printing materials and other simulated rigid bodies in the environment, which is not available for roboticists yet. To bridge this gap and enable the real-time simulation of mobile 3D printing processes, we develop a simulation framework that includes particle-based viscoelastic fluid simulation and particle-to-mesh conversion in the widely adopted Gazebo robotics simulator, avoiding the bottlenecks of traditional additive manufacturing simulation approaches. This framework is the first of its kind that enables the simulation of robot arms or mobile manipulators together with viscoelastic fluids. The method is tested using various material properties and multiple collaborating robots to demonstrate its simulation ability for the robots to plan and control the printhead trajectories and to visually sense at the same time the printed fluid materials as a free-form mesh. The scalability as a function of available material particles in the simulation was also studied. A simulation with an average of 5 FPS was achieved on a regular desktop computer.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge