LightDefectNet: A Highly Compact Deep Anti-Aliased Attention Condenser Neural Network Architecture for Light Guide Plate Surface Defect Detection

Paper and Code

Apr 25, 2022

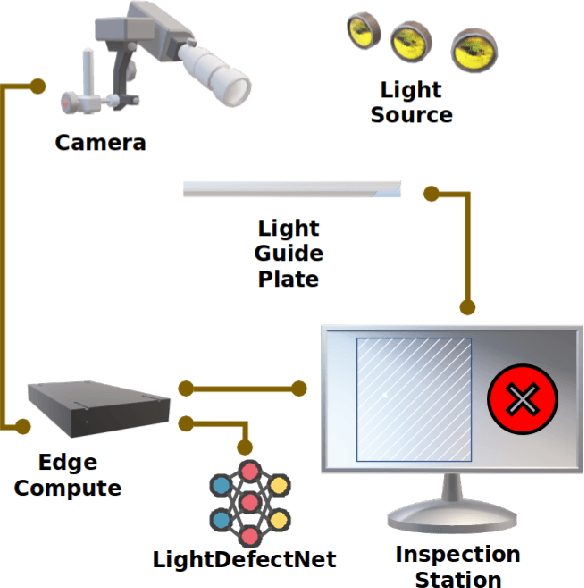

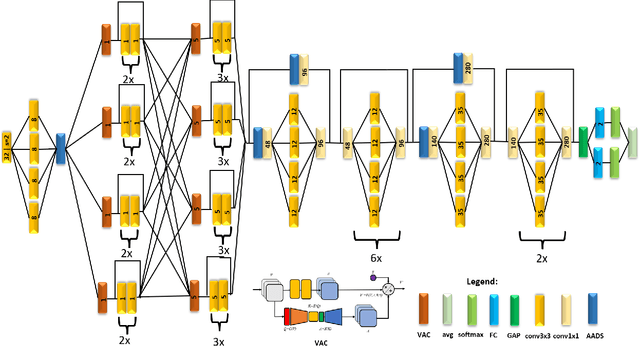

Light guide plates are essential optical components widely used in a diverse range of applications ranging from medical lighting fixtures to back-lit TV displays. An essential step in the manufacturing of light guide plates is the quality inspection of defects such as scratches, bright/dark spots, and impurities. This is mainly done in industry through manual visual inspection for plate pattern irregularities, which is time-consuming and prone to human error and thus act as a significant barrier to high-throughput production. Advances in deep learning-driven computer vision has led to the exploration of automated visual quality inspection of light guide plates to improve inspection consistency, accuracy, and efficiency. However, given the cost constraints in visual inspection scenarios, the widespread adoption of deep learning-driven computer vision methods for inspecting light guide plates has been greatly limited due to high computational requirements. In this study, we explore the utilization of machine-driven design exploration with computational and "best-practices" constraints as well as L$_1$ paired classification discrepancy loss to create LightDefectNet, a highly compact deep anti-aliased attention condenser neural network architecture tailored specifically for light guide plate surface defect detection in resource-constrained scenarios. Experiments show that LightDetectNet achieves a detection accuracy of $\sim$98.2% on the LGPSDD benchmark while having just 770K parameters ($\sim$33$\times$ and $\sim$6.9$\times$ lower than ResNet-50 and EfficientNet-B0, respectively) and $\sim$93M FLOPs ($\sim$88$\times$ and $\sim$8.4$\times$ lower than ResNet-50 and EfficientNet-B0, respectively) and $\sim$8.8$\times$ faster inference speed than EfficientNet-B0 on an embedded ARM processor.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge