Imitation and Supervised Learning of Compliance for Robotic Assembly

Paper and Code

Nov 20, 2021

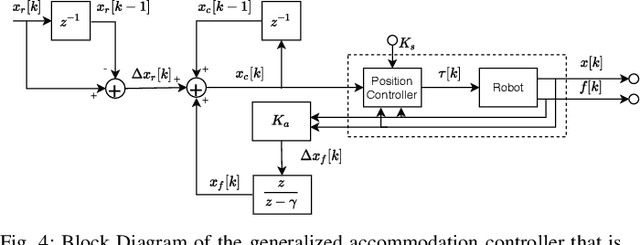

We present the design of a learning-based compliance controller for assembly operations for industrial robots. We propose a solution within the general setting of learning from demonstration (LfD), where a nominal trajectory is provided through demonstration by an expert teacher. This can be used to learn a suitable representation of the skill that can be generalized to novel positions of one of the parts involved in the assembly, for example the hole in a peg-in-hole (PiH) insertion task. Under the expectation that this novel position might not be entirely accurately estimated by a vision or other sensing system, the robot will need to further modify the generated trajectory in response to force readings measured by means of a force-torque (F/T) sensor mounted at the wrist of the robot or another suitable location. Under the assumption of constant velocity of traversing the reference trajectory during assembly, we propose a novel accommodation force controller that allows the robot to safely explore different contact configurations. The data collected using this controller is used to train a Gaussian process model to predict the misalignment in the position of the peg with respect to the target hole. We show that the proposed learning-based approach can correct various contact configurations caused by misalignment between the assembled parts in a PiH task, achieving high success rate during insertion. We show results using an industrial manipulator arm, and demonstrate that the proposed method can perform adaptive insertion using force feedback from the trained machine learning models.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge