Forecasting Industrial Aging Processes with Machine Learning Methods

Paper and Code

Feb 05, 2020

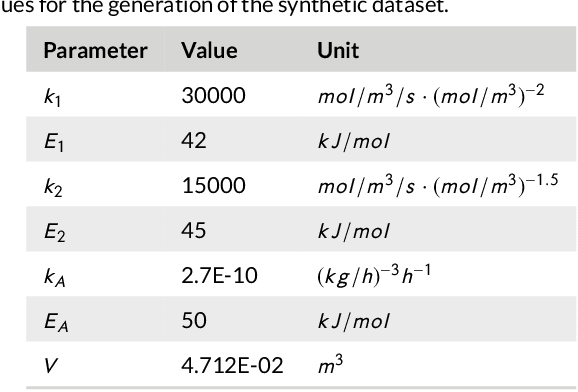

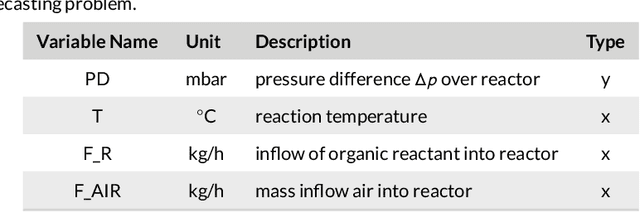

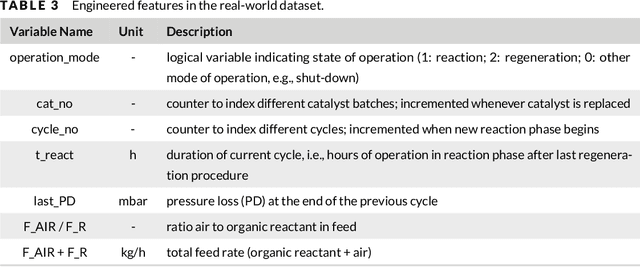

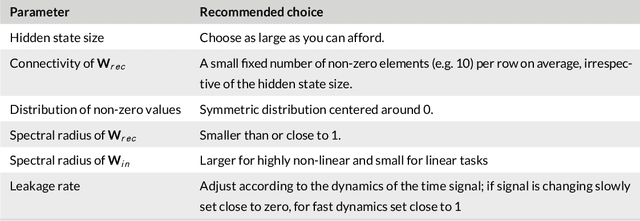

By accurately predicting industrial aging processes (IAPs), it is possible to schedule maintenance events further in advance, thereby ensuring a cost-efficient and reliable operation of the plant. So far, these degradation processes were usually described by mechanistic models or simple empirical prediction models. In this paper, we evaluate a wider range of data-driven models for this task, comparing some traditional stateless models (linear and kernel ridge regression, feed-forward neural networks) to more complex recurrent neural networks (echo state networks and LSTMs). To examine how much historical data is needed to train each of the models, we first examine their performance on a synthetic dataset with known dynamics. Next, the models are tested on real-world data from a large scale chemical plant. Our results show that LSTMs produce near perfect predictions when trained on a large enough dataset, while linear models may generalize better given small datasets with changing conditions.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge