Divide et Impera: Learning impedance families for peg-in-hole assembly

Paper and Code

Oct 01, 2024

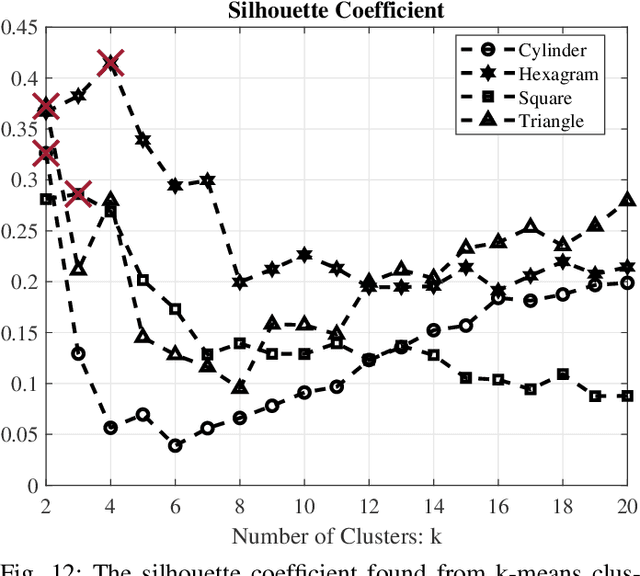

This paper addresses robotic peg-in-hole assembly using the framework of Elementary Dynamic Actions (EDA). Inspired by motor primitives in neuromotor control research, the method leverages three primitives: submovements, oscillations, and mechanical impedances (e.g., stiffness and damping), combined via a Norton equivalent network model. By focusing on impedance parameterization, we explore the adaptability of EDA in contact-rich tasks. Experimental results, conducted on a real robot setup with four different peg types, demonstrated a range of successful impedance parameters, challenging conventional methods that seek optimal parameters. We analyze our data in a lower-dimensional solution space. Clustering analysis shows the possibility to identify different individual strategies for each single peg, as well as common strategies across all pegs. A neural network model, trained on the experimental data, accurately predicted successful impedance parameters across all pegs. The practical utility of this work is enhanced by a success-predictor model and the public availability of all code and CAD files. These findings highlight the flexibility and robustness of EDA; show multiple equally-successful strategies for contact-rich manipulation; and offer valuable insights and tools for robotic assembly programming.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge