Development of a Vision System to Enhance the Reliability of the Pick-and-Place Robot for Autonomous Testing of Camera Module used in Smartphones

Paper and Code

May 08, 2023

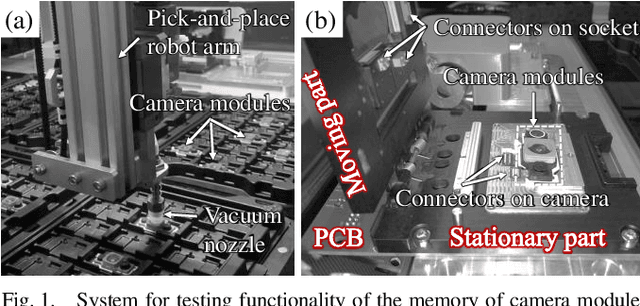

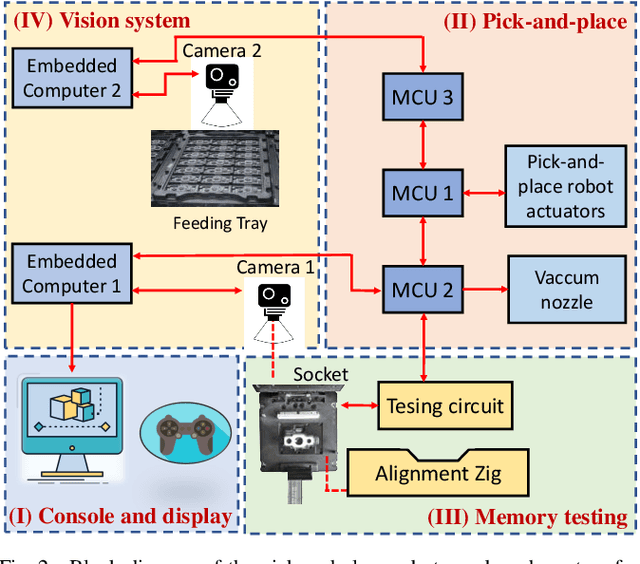

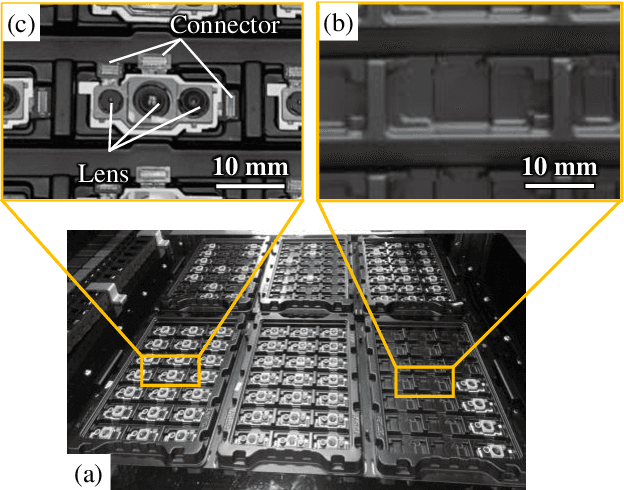

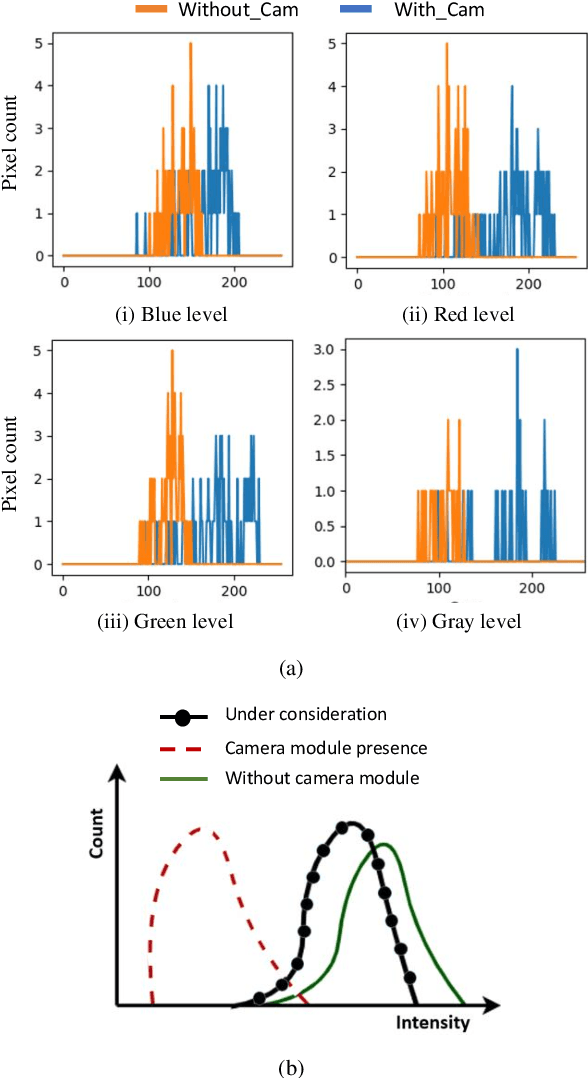

Pick-and-place robots are commonly used in modern industrial manufacturing. For complex devices/parts like camera modules used in smartphones, which contain optical parts, electrical components and interfacing connectors, the placement operation may not absolutely accurate, which may cause damage in the device under test during the mechanical movement to make good contact for electrical functions inspection. In this paper, we proposed an effective vision system including hardware and algorithm to enhance the reliability of the pick-and-place robot for autonomous testing memory of camera modules. With limited hardware based on camera and raspberry PI and using simplify image processing algorithm based on histogram information, the vision system can confirm the presence of the camera modules in feeding tray and the placement accuracy of the camera module in test socket. Through that, the system can work with more flexibility and avoid damaging the device under test. The system was experimentally quantified through testing approximately 2000 camera modules in a stable light condition. Experimental results demonstrate that the system achieves accuracy of more than 99.92%. With its simplicity and effectiveness, the proposed vision system can be considered as a useful solution for using in pick-and-place systems in industry.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge