Cutting Sequence Diffuser: Sim-to-Real Transferable Planning for Object Shaping by Grinding

Paper and Code

Dec 19, 2024

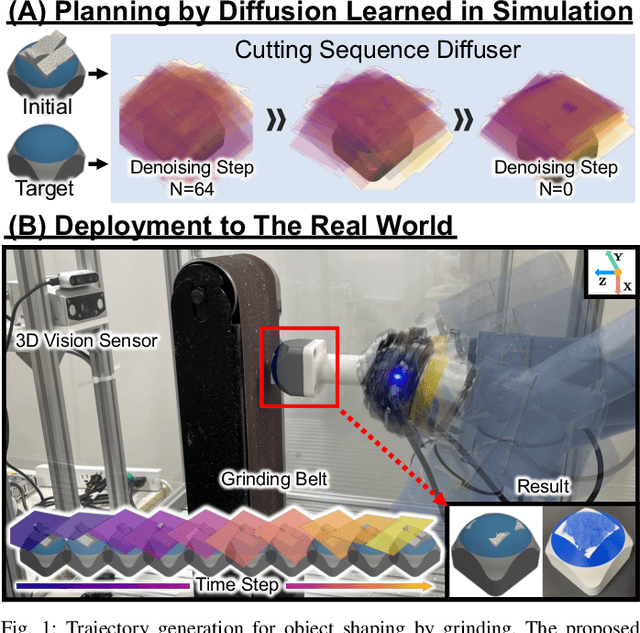

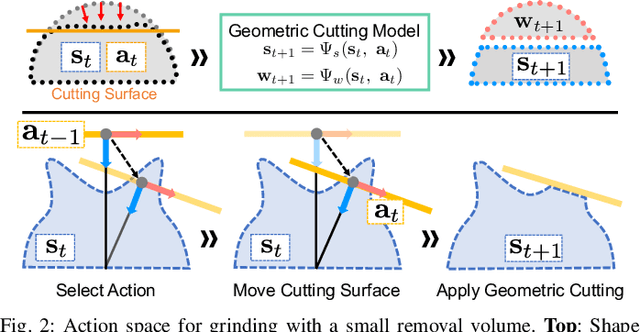

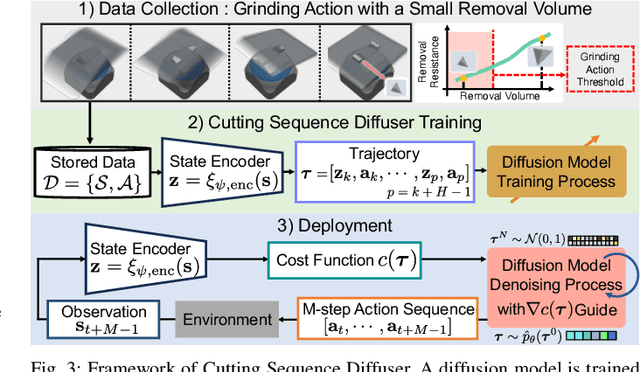

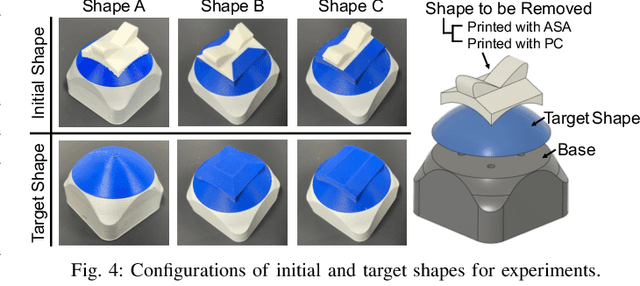

Automating object shaping by grinding with a robot is a crucial industrial process that involves removing material with a rotating grinding belt. This process generates removal resistance depending on such process conditions as material type, removal volume, and robot grinding posture, all of which complicate the analytical modeling of shape transitions. Additionally, a data-driven approach based on real-world data is challenging due to high data collection costs and the irreversible nature of the process. This paper proposes a Cutting Sequence Diffuser (CSD) for object shaping by grinding. The CSD, which only requires simple simulation data for model learning, offers an efficient way to plan long-horizon action sequences transferable to the real world. Our method designs a smooth action space with constrained small removal volumes to suppress the complexity of the shape transitions caused by removal resistance, thus reducing the reality gap in simulations. Moreover, by using a diffusion model to generate long-horizon action sequences, our approach reduces the planning time and allows for grinding the target shape while adhering to the constraints of a small removal volume per step. Through evaluations in both simulation and real robot experiments, we confirmed that our CSD was effective for grinding to different materials and various target shapes in a short time.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge