Application-Oriented Co-Design of Motors and Motions for a 6DOF Robot Manipulator

Paper and Code

Oct 04, 2023

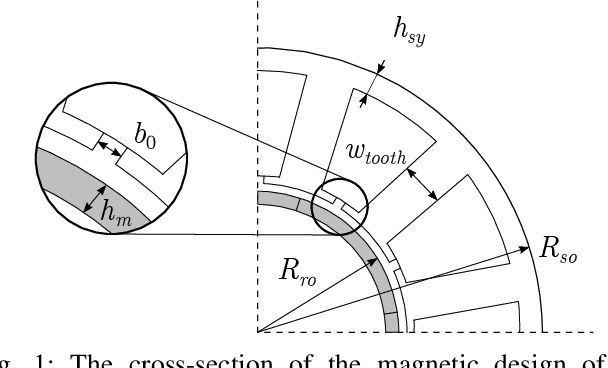

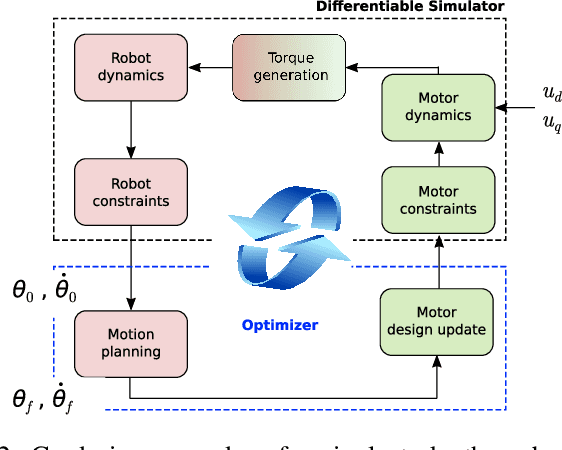

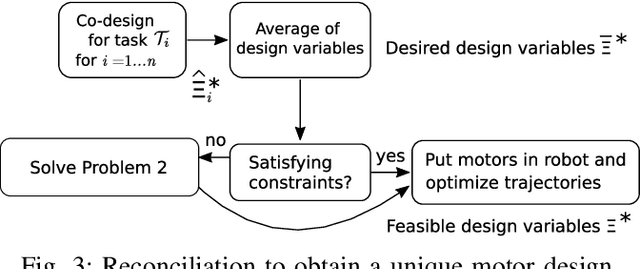

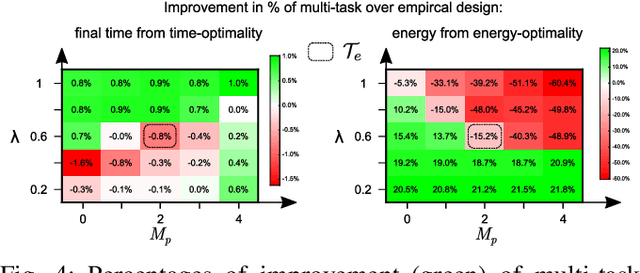

This work investigates an application-driven co-design problem where the motion and motors of a six degrees of freedom robotic manipulator are optimized simultaneously, and the application is characterized by a set of tasks. Unlike the state-of-the-art which selects motors from a product catalogue and performs co-design for a single task, this work designs the motor geometry as well as motion for a specific application. Contributions are made towards solving the proposed co-design problem in a computationally-efficient manner. First, a two-step process is proposed, where multiple motor designs are identified by optimizing motions and motors for multiple tasks one by one, and then are reconciled to determine the final motor design. Second, magnetic equivalent circuit modeling is exploited to establish the analytic mapping from motor design parameters to dynamic models and objective functions to facilitate the subsequent differentiable simulation. Third, a direct-collocation-based differentiable simulator of motor and robotic arm dynamics is developed to balance the computational complexity and numerical stability. Simulation verifies that higher performance for a specific application can be achieved with the multi-task method, compared to several benchmark co-design methods.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge