A Flexible and Robust Large Scale Capacitive Tactile System for Robots

Paper and Code

Nov 25, 2014

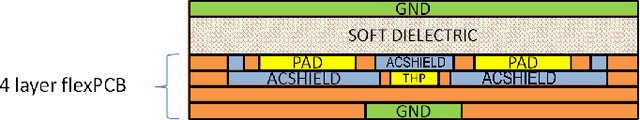

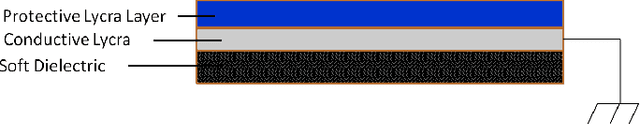

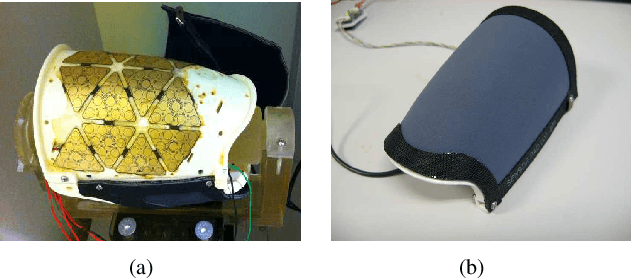

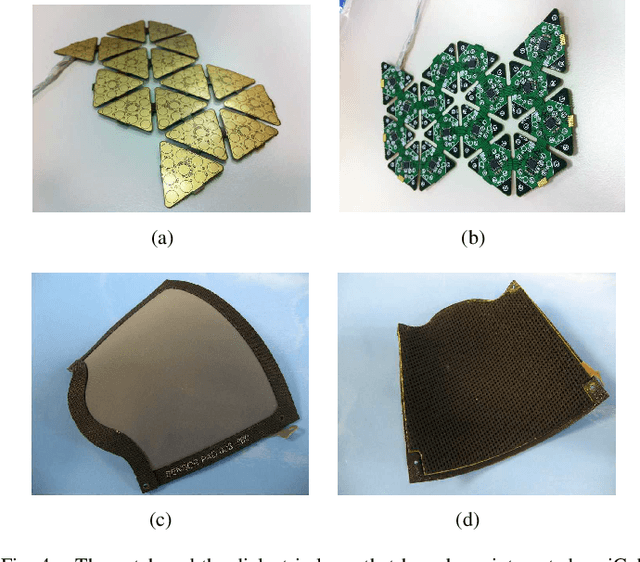

Capacitive technology allows building sensors that are small, compact and have high sensitivity. For this reason it has been widely adopted in robotics. In a previous work we presented a compliant skin system based on capacitive technology consisting of triangular modules interconnected to form a system of sensors that can be deployed on non-flat surfaces. This solution has been successfully adopted to cover various humanoid robots. The main limitation of this and all the approaches based on capacitive technology is that they require to embed a deformable dielectric layer (usually made using an elastomer) covered by a conductive layer. This complicates the production process considerably, introduces hysteresis and limits the durability of the sensors due to ageing and mechanical stress. In this paper we describe a novel solution in which the dielectric is made using a thin layer of 3D fabric which is glued to conductive and protective layers using techniques adopted in the clothing industry. As such, the sensor is easier to produce and has better mechanical properties. Furthermore, the sensor proposed in this paper embeds transducers for thermal compensation of the pressure measurements. We report experimental analysis that demonstrates that the sensor has good properties in terms of sensitivity and resolution. Remarkably we show that the sensor has very low hysteresis and effectively allows compensating drifts due to temperature variations.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge