Zhenzhen Huang

DefFiller: Mask-Conditioned Diffusion for Salient Steel Surface Defect Generation

Dec 20, 2024

Abstract:Current saliency-based defect detection methods show promise in industrial settings, but the unpredictability of defects in steel production environments complicates dataset creation, hampering model performance. Existing data augmentation approaches using generative models often require pixel-level annotations, which are time-consuming and resource-intensive. To address this, we introduce DefFiller, a mask-conditioned defect generation method that leverages a layout-to-image diffusion model. DefFiller generates defect samples paired with mask conditions, eliminating the need for pixel-level annotations and enabling direct use in model training. We also develop an evaluation framework to assess the quality of generated samples and their impact on detection performance. Experimental results on the SD-Saliency-900 dataset demonstrate that DefFiller produces high-quality defect images that accurately match the provided mask conditions, significantly enhancing the performance of saliency-based defect detection models trained on the augmented dataset.

Defect Image Sample Generation With Diffusion Prior for Steel Surface Defect Recognition

May 03, 2024

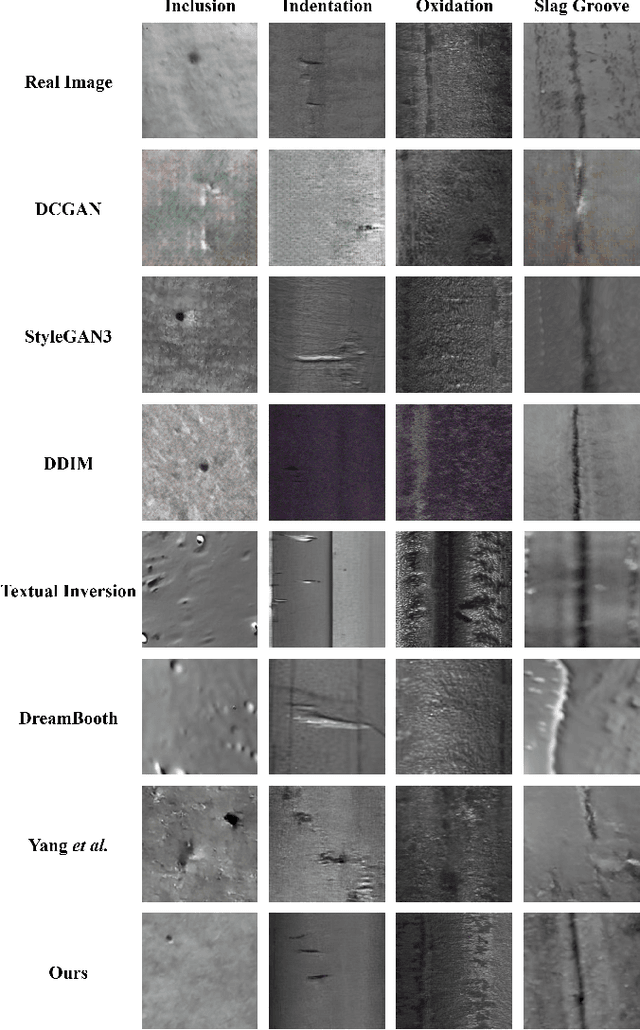

Abstract:The task of steel surface defect recognition is an industrial problem with great industry values. The data insufficiency is the major challenge in training a robust defect recognition network. Existing methods have investigated to enlarge the dataset by generating samples with generative models. However, their generation quality is still limited by the insufficiency of defect image samples. To this end, we propose Stable Surface Defect Generation (StableSDG), which transfers the vast generation distribution embedded in Stable Diffusion model for steel surface defect image generation. To tackle with the distinctive distribution gap between steel surface images and generated images of the diffusion model, we propose two processes. First, we align the distribution by adapting parameters of the diffusion model, adopted both in the token embedding space and network parameter space. Besides, in the generation process, we propose image-oriented generation rather than from pure Gaussian noises. We conduct extensive experiments on steel surface defect dataset, demonstrating state-of-the-art performance on generating high-quality samples and training recognition models, and both designed processes are significant for the performance.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge