Yvonne Richter

Cutting Through the Noise: An Empirical Comparison of Psychoacoustic and Envelope-based Features for Machinery Fault Detection

Nov 03, 2022

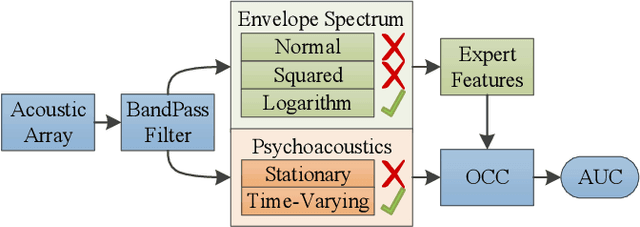

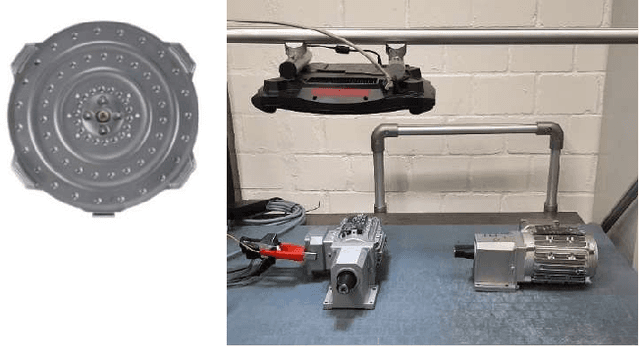

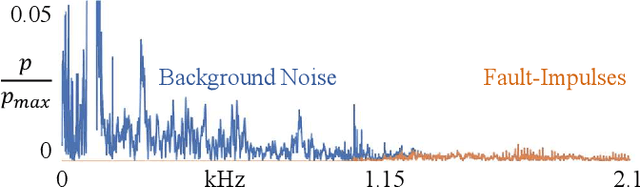

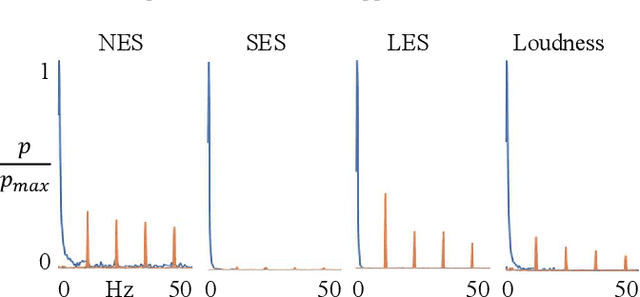

Abstract:Acoustic-based fault detection has a high potential to monitor the health condition of mechanical parts. However, the background noise of an industrial environment may negatively influence the performance of fault detection. Limited attention has been paid to improving the robustness of fault detection against industrial environmental noise. Therefore, we present the Lenze production background-noise (LPBN) real-world dataset and an automated and noise-robust auditory inspection (ARAI) system for the end-of-line inspection of geared motors. An acoustic array is used to acquire data from motors with a minor fault, major fault, or which are healthy. A benchmark is provided to compare the psychoacoustic features with different types of envelope features based on expert knowledge of the gearbox. To the best of our knowledge, we are the first to apply time-varying psychoacoustic features for fault detection. We train a state-of-the-art one-class-classifier, on samples from healthy motors and separate the faulty ones for fault detection using a threshold. The best-performing approaches achieve an area under curve of 0.87 (logarithm envelope), 0.86 (time-varying psychoacoustics), and 0.91 (combination of both).

Discussion of Features for Acoustic Anomaly Detection under Industrial Disturbing Noise in an End-of-Line Test of Geared Motors

Nov 03, 2022

Abstract:In the end-of-line test of geared motors, the evaluation of product qual-ity is important. Due to time constraints and the high diversity of variants, acous-tic measurements are more economical than vibration measurements. However, the acoustic data is affected by industrial disturbing noise. Therefore, the aim of this study is to investigate the robustness of features used for anomaly detection in geared motor end-of-line testing. A real-world dataset with typical faults and acoustic disturbances is recorded by an acoustic array. This includes industrial noise from the production and systematically produced disturbances, used to compare the robustness. Overall, it is proposed to apply features extracted from a log-envelope spectrum together with psychoacoustic features. The anomaly de-tection is done by using the isolation forest or the more universal bagging random miner. Most disturbances can be circumvented, while the use of a hammer or air pressure often causes problems. In general, these results are important for condi-tion monitoring tasks that are based on acoustic or vibration measurements. Fur-thermore, a real-world problem description is presented to improve common sig-nal processing and machine learning tasks.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge