Yongmin Kwon

Three-dimensional Deep Shape Optimization with a Limited Dataset

Jun 14, 2025Abstract:Generative models have attracted considerable attention for their ability to produce novel shapes. However, their application in mechanical design remains constrained due to the limited size and variability of available datasets. This study proposes a deep learning-based optimization framework specifically tailored for shape optimization with limited datasets, leveraging positional encoding and a Lipschitz regularization term to robustly learn geometric characteristics and maintain a meaningful latent space. Through extensive experiments, the proposed approach demonstrates robustness, generalizability and effectiveness in addressing typical limitations of conventional optimization frameworks. The validity of the methodology is confirmed through multi-objective shape optimization experiments conducted on diverse three-dimensional datasets, including wheels and cars, highlighting the model's versatility in producing practical and high-quality design outcomes even under data-constrained conditions.

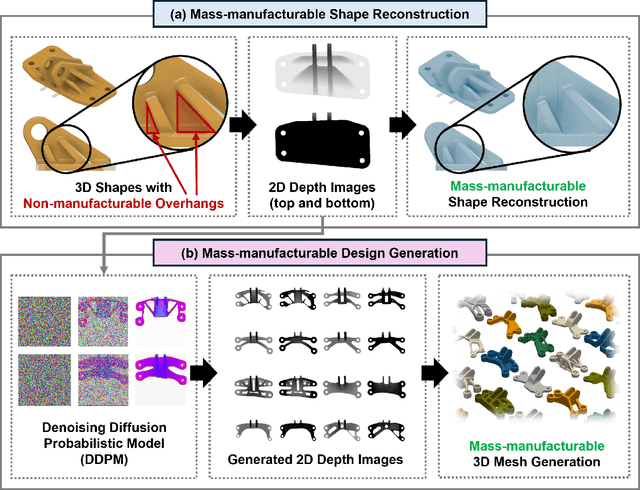

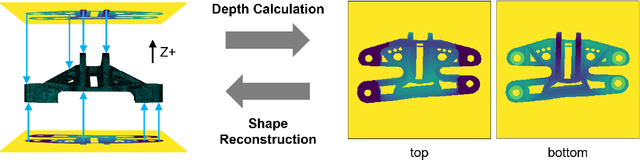

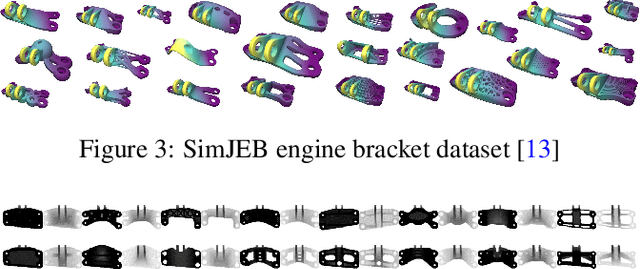

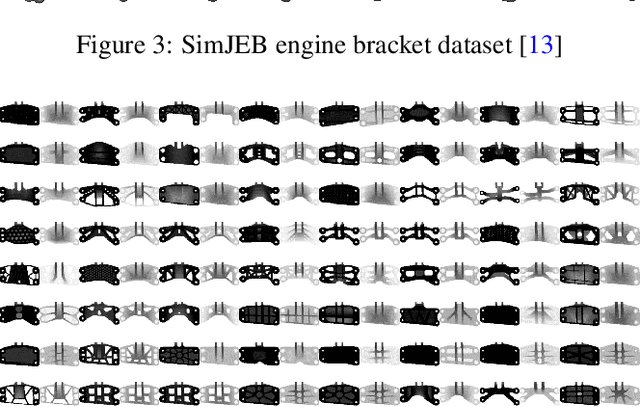

Deep Generative Design for Mass Production

Mar 16, 2024

Abstract:Generative Design (GD) has evolved as a transformative design approach, employing advanced algorithms and AI to create diverse and innovative solutions beyond traditional constraints. Despite its success, GD faces significant challenges regarding the manufacturability of complex designs, often necessitating extensive manual modifications due to limitations in standard manufacturing processes and the reliance on additive manufacturing, which is not ideal for mass production. Our research introduces an innovative framework addressing these manufacturability concerns by integrating constraints pertinent to die casting and injection molding into GD, through the utilization of 2D depth images. This method simplifies intricate 3D geometries into manufacturable profiles, removing unfeasible features such as non-manufacturable overhangs and allowing for the direct consideration of essential manufacturing aspects like thickness and rib design. Consequently, designs previously unsuitable for mass production are transformed into viable solutions. We further enhance this approach by adopting an advanced 2D generative model, which offer a more efficient alternative to traditional 3D shape generation methods. Our results substantiate the efficacy of this framework, demonstrating the production of innovative, and, importantly, manufacturable designs. This shift towards integrating practical manufacturing considerations into GD represents a pivotal advancement, transitioning from purely inspirational concepts to actionable, production-ready solutions. Our findings underscore usefulness and potential of GD for broader industry adoption, marking a significant step forward in aligning GD with the demands of manufacturing challenges.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge