Tamal Ghosh

An effective AHP-based metaheuristic approach to solve supplier selection problem

Apr 15, 2014

Abstract:The supplier selection problem is based on electing the best supplier from a group of pre-specified candidates, is identified as a Multi Criteria Decision Making (MCDM), is proportionately significant in terms of qualitative and quantitative attributes. It is a fundamental issue to achieve a trade-off between such quantifiable and unquantifiable attributes with an aim to accomplish the best solution to the abovementioned problem. This article portrays a metaheuristic based optimization model to solve this NP-Complete problem. Initially the Analytic Hierarchy Process (AHP) is implemented to generate an initial feasible solution of the problem. Thereafter a Simulated Annealing (SA) algorithm is exploited to improve the quality of the obtained solution. The Taguchi robust design method is exploited to solve the critical issues on the subject of the parameter selection of the SA technique. In order to verify the proposed methodology the numerical results are demonstrated based on tangible industry data.

Neural Network Influence in Group Technology: A Chronological Survey and Critical Analysis

Dec 21, 2012Abstract:This article portrays a chronological review of the influence of Artificial Neural Network in group technology applications in the vicinity of Cellular Manufacturing Systems. The research trend is identified and the evolvement is captured through a critical analysis of the literature accessible from the very beginning of its practice in the early 90's till the 2010. Analysis of the diverse ANN approaches, spotted research pattern, comparison of the clustering efficiencies, the solutions obtained and the tools used make this study exclusive in its class.

Hybrid Fuzzy-ART based K-Means Clustering Methodology to Cellular Manufacturing Using Operational Time

Dec 20, 2012

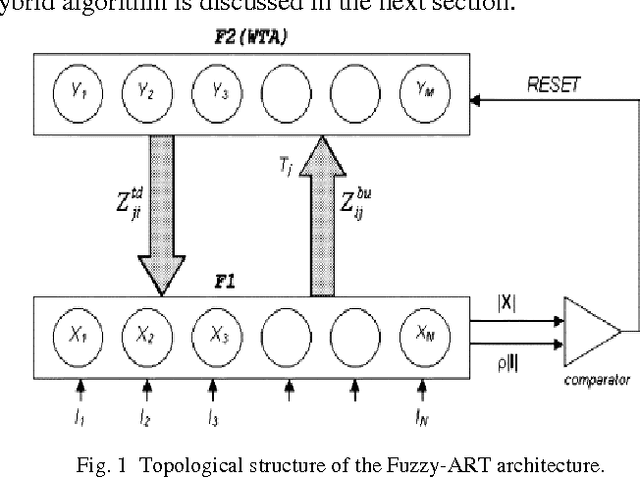

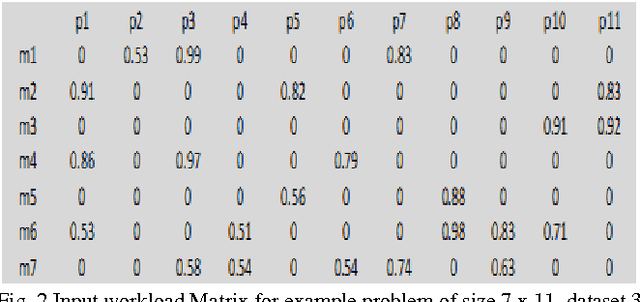

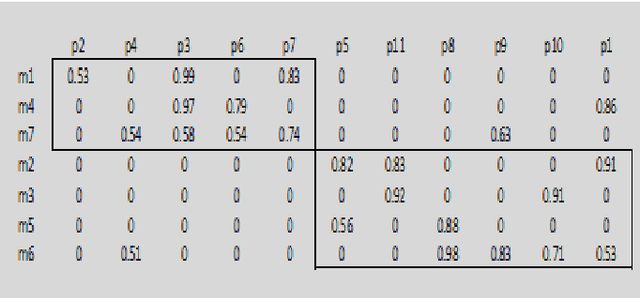

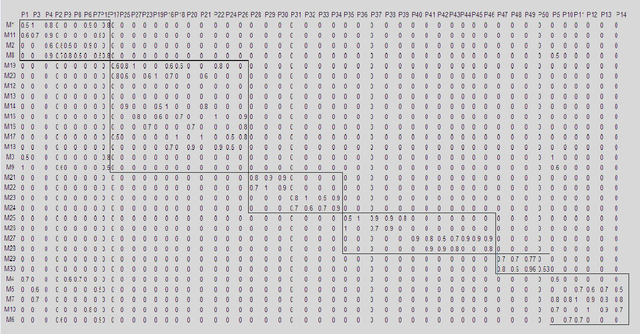

Abstract:This paper presents a new hybrid Fuzzy-ART based K-Means Clustering technique to solve the part machine grouping problem in cellular manufacturing systems considering operational time. The performance of the proposed technique is tested with problems from open literature and the results are compared to the existing clustering models such as simple K-means algorithm and modified ART1 algorithm using an efficient modified performance measure known as modified grouping efficiency (MGE) as found in the literature. The results support the better performance of the proposed algorithm. The Novelty of this study lies in the simple and efficient methodology to produce quick solutions for shop floor managers with least computational efforts and time.

SAPFOCS: a metaheuristic based approach to part family formation problems in group technology

May 11, 2011Abstract:This article deals with Part family formation problem which is believed to be moderately complicated to be solved in polynomial time in the vicinity of Group Technology (GT). In the past literature researchers investigated that the part family formation techniques are principally based on production flow analysis (PFA) which usually considers operational requirements, sequences and time. Part Coding Analysis (PCA) is merely considered in GT which is believed to be the proficient method to identify the part families. PCA classifies parts by allotting them to different families based on their resemblances in: (1) design characteristics such as shape and size, and/or (2) manufacturing characteristics (machining requirements). A novel approach based on simulated annealing namely SAPFOCS is adopted in this study to develop effective part families exploiting the PCA technique. Thereafter Taguchi's orthogonal design method is employed to solve the critical issues on the subject of parameters selection for the proposed metaheuristic algorithm. The adopted technique is therefore tested on 5 different datasets of size 5 {\times} 9 to 27 {\times} 9 and the obtained results are compared with C-Linkage clustering technique. The experimental results reported that the proposed metaheuristic algorithm is extremely effective in terms of the quality of the solution obtained and has outperformed C-Linkage algorithm in most instances.

* 10 pages; 6 figures; 12 tables

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge