Stephan Baggerohr

Graph Neural Networks for Virtual Sensing in Complex Systems: Addressing Heterogeneous Temporal Dynamics

Jul 26, 2024

Abstract:Real-time condition monitoring is crucial for the reliable and efficient operation of complex systems. However, relying solely on physical sensors can be limited due to their cost, placement constraints, or inability to directly measure certain critical parameters. Virtual sensing addresses these limitations by leveraging readily available sensor data and system knowledge to estimate inaccessible parameters or infer system states. The increasing complexity of industrial systems necessitates deployments of sensors with diverse modalities to provide a comprehensive understanding of system states. These sensors capture data at varying frequencies to monitor both rapid and slowly varying system dynamics, as well as local and global state evolutions of the systems. This leads to heterogeneous temporal dynamics, which, particularly under varying operational end environmental conditions, pose a significant challenge for accurate virtual sensing. To address this, we propose a Heterogeneous Temporal Graph Neural Network (HTGNN) framework. HTGNN explicitly models signals from diverse sensors and integrates operating conditions into the model architecture. We evaluate HTGNN using two newly released datasets: a bearing dataset with diverse load conditions for bearing load prediction and a year-long simulated dataset for predicting bridge live loads. Our results demonstrate that HTGNN significantly outperforms established baseline methods in both tasks, particularly under highly varying operating conditions. These results highlight HTGNN's potential as a robust and accurate virtual sensing approach for complex systems, paving the way for improved monitoring, predictive maintenance, and enhanced system performance.

Virtual Sensor for Real-Time Bearing Load Prediction Using Heterogeneous Temporal Graph Neural Networks

Apr 02, 2024

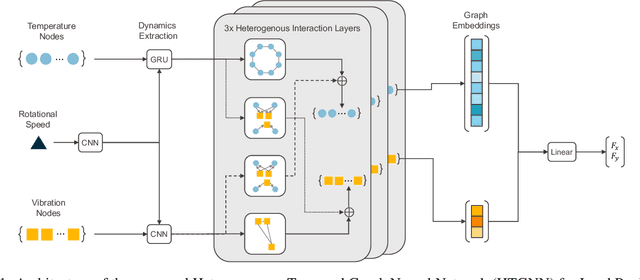

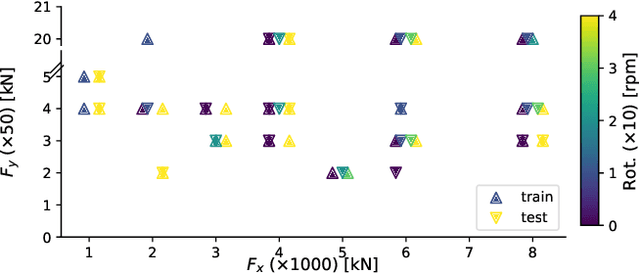

Abstract:Accurate bearing load monitoring is essential for their Prognostics and Health Management (PHM), enabling damage assessment, wear prediction, and proactive maintenance. While bearing sensors are typically placed on the bearing housing, direct load monitoring requires sensors inside the bearing itself. Recently introduced sensor rollers enable direct bearing load monitoring but are constrained by their battery life. Data-driven virtual sensors can learn from sensor roller data collected during a batterys lifetime to map operating conditions to bearing loads. Although spatially distributed bearing sensors offer insights into load distribution (e.g., correlating temperature with load), traditional machine learning algorithms struggle to fully exploit these spatial-temporal dependencies. To address this gap, we introduce a graph-based virtual sensor that leverages Graph Neural Networks (GNNs) to analyze spatial-temporal dependencies among sensor signals, mapping existing measurements (temperature, vibration) to bearing loads. Since temperature and vibration signals exhibit vastly different dynamics, we propose Heterogeneous Temporal Graph Neural Networks (HTGNN), which explicitly models these signal types and their interactions for effective load prediction. Our results demonstrate that HTGNN outperforms Convolutional Neural Networks (CNNs), which struggle to capture both spatial and heterogeneous signal characteristics. These findings highlight the importance of capturing the complex spatial interactions between temperature, vibration, and load.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge