Snigdha Agarwal

for Group Data and Analytics, Aditya Birla Group

Chest X-ray Classification using Deep Convolution Models on Low-resolution images with Uncertain Labels

Apr 12, 2025Abstract:Deep Convolutional Neural Networks have consistently proven to achieve state-of-the-art results on a lot of imaging tasks over the past years' majority of which comprise of high-quality data. However, it is important to work on low-resolution images since it could be a cheaper alternative for remote healthcare access where the primary need of automated pathology identification models occurs. Medical diagnosis using low-resolution images is challenging since critical details may not be easily identifiable. In this paper, we report classification results by experimenting on different input image sizes of Chest X-rays to deep CNN models and discuss the feasibility of classification on varying image sizes. We also leverage the noisy labels in the dataset by proposing a Randomized Flipping of labels techniques. We use an ensemble of multi-label classification models on frontal and lateral studies. Our models are trained on 5 out of the 14 chest pathologies of the publicly available CheXpert dataset. We incorporate techniques such as augmentation, regularization for model improvement and use class activation maps to visualize the neural network's decision making. Comparison with classification results on data from 200 subjects, obtained on the corresponding high-resolution images, reported in the original CheXpert paper, has been presented. For pathologies Cardiomegaly, Consolidation and Edema, we obtain 3% higher accuracy with our model architecture.

Graph Classification and Radiomics Signature for Identification of Tuberculous Meningitis

Apr 01, 2025

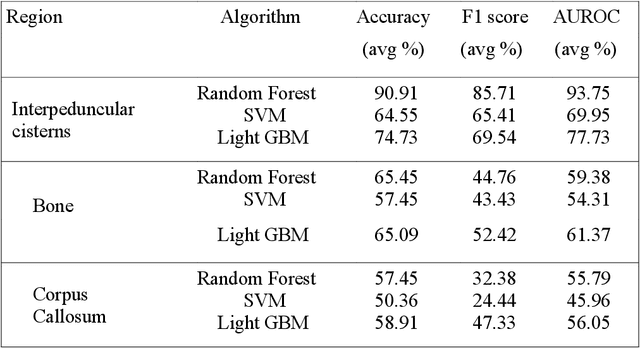

Abstract:Introduction: Tuberculous meningitis (TBM) is a serious brain infection caused by Mycobacterium tuberculosis, characterized by inflammation of the meninges covering the brain and spinal cord. Diagnosis often requires invasive lumbar puncture (LP) and cerebrospinal fluid (CSF) analysis. Objectives: This study aims to classify TBM patients using T1-weighted (T1w) non-contrast Magnetic Resonance Imaging (MRI) scans. We hypothesize that specific brain regions, such as the interpeduncular cisterns, bone, and corpus callosum, contain visual markers that can non-invasively distinguish TBM patients from healthy controls. We propose a novel Pixel-array Graphs Classifier (PAG-Classifier) that leverages spatial relationships between neighbouring 3D pixels in a graph-based framework to extract significant features through eigen decomposition. These features are then used to train machine learning classifiers for effective patient classification. We validate our approach using a radiomics-based methodology, classifying TBM patients based on relevant radiomics features. Results: We utilized an internal dataset consisting of 52 scans, 32 from confirmed TBM patients based on mycobacteria detection in CSF, and 20 from healthy individuals. We achieved a 5-fold cross-validated average F1 score of 85.71% for cistern regions with our PAG-Classifier and 92.85% with the radiomics features classifier, surpassing current state-of-the-art benchmarks by 15% and 22%, respectively. However, bone and corpus callosum regions showed poor classification effectiveness, with average F1 scores below 50%. Conclusion: Our study suggests that algorithms like the PAG-Classifier serve as effective tools for non-invasive TBM analysis, particularly by targeting the interpeduncular cistern. Findings indicate that the bone and corpus callosum regions lack distinctive patterns for differentiation.

Using Computer Vision to enhance Safety of Workforce in Manufacturing in a Post COVID World

May 25, 2020

Abstract:The COVID-19 pandemic forced governments across the world to impose lockdowns to prevent virus transmissions. This resulted in the shutdown of all economic activity and accordingly the production at manufacturing plants across most sectors was halted. While there is an urgency to resume production, there is an even greater need to ensure the safety of the workforce at the plant site. Reports indicate that maintaining social distancing and wearing face masks while at work clearly reduces the risk of transmission. We decided to use computer vision on CCTV feeds to monitor worker activity and detect violations which trigger real time voice alerts on the shop floor. This paper describes an efficient and economic approach of using AI to create a safe environment in a manufacturing setup. We demonstrate our approach to build a robust social distancing measurement algorithm using a mix of modern-day deep learning and classic projective geometry techniques. We have deployed our solution at manufacturing plants across the Aditya Birla Group (ABG). We have also described our face mask detection approach which provides a high accuracy across a range of customized masks.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge