Shikui Wang

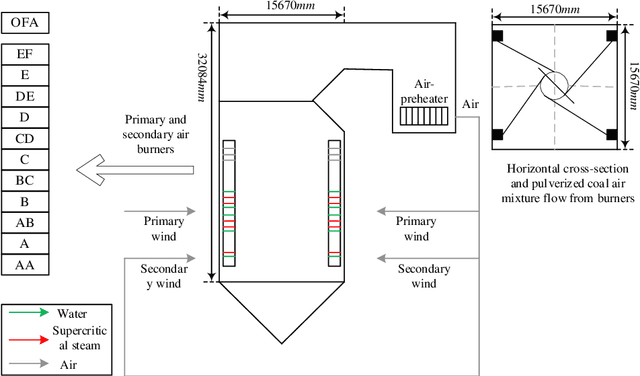

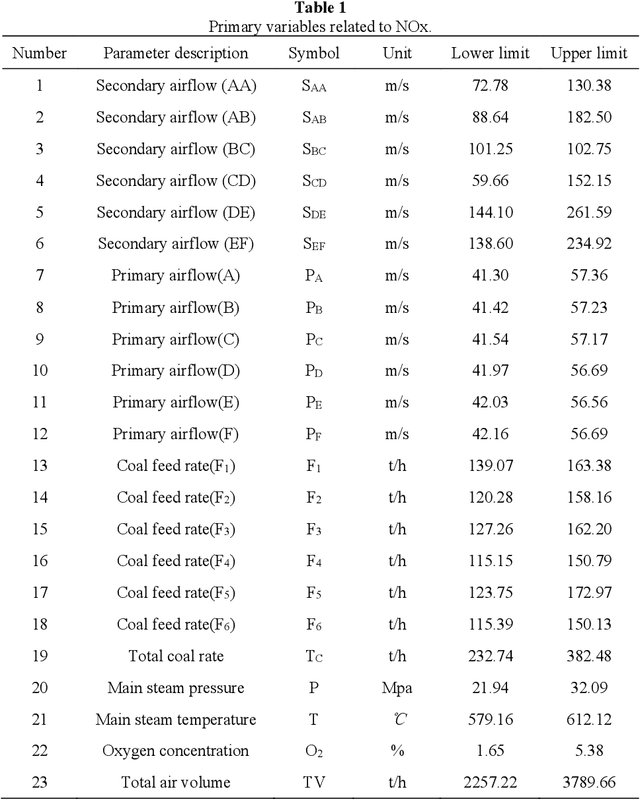

Auto-Encoder-Extreme Learning Machine Model for Boiler NOx Emission Concentration Prediction

Jun 29, 2022

Abstract:An automatic encoder (AE) extreme learning machine (ELM)-AE-ELM model is proposed to predict the NOx emission concentration based on the combination of mutual information algorithm (MI), AE, and ELM. First, the importance of practical variables is computed by the MI algorithm, and the mechanism is analyzed to determine the variables related to the NOx emission concentration. Then, the time delay correlations between the selected variables and NOx emission concentration are further analyzed to reconstruct the modeling data. Subsequently, the AE is applied to extract hidden features within the input variables. Finally, an ELM algorithm establishes the relationship between the NOx emission concentration and deep features. The experimental results on practical data indicate that the proposed model shows promising performance compared to state-of-art models.

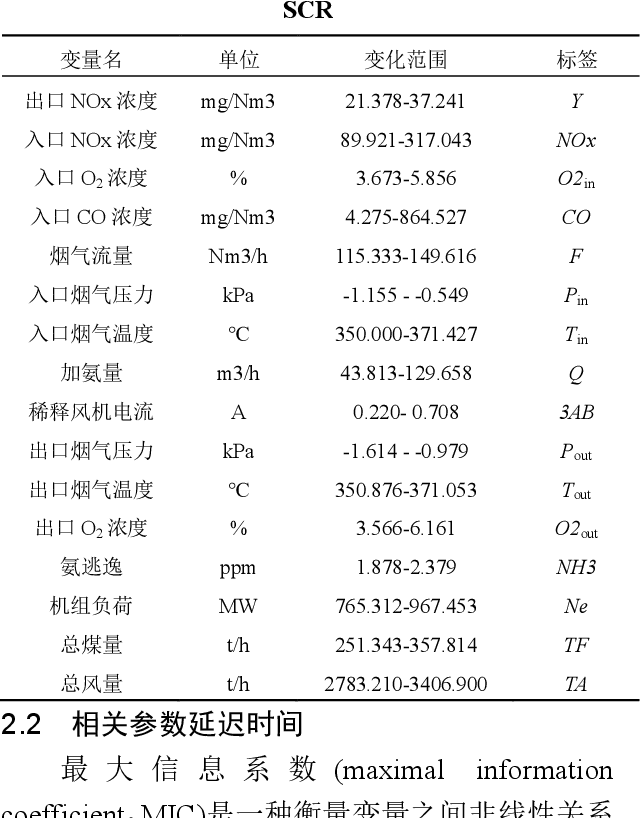

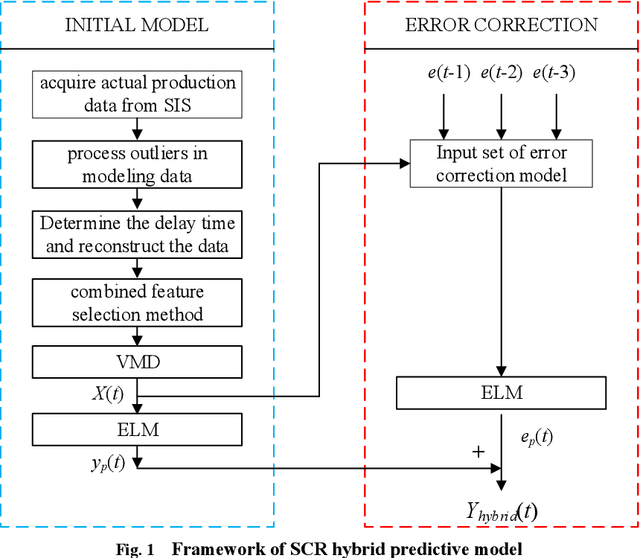

Dynamic Prediction Model for NOx Emission of SCR System Based on Hybrid Data-driven Algorithms

Aug 03, 2021

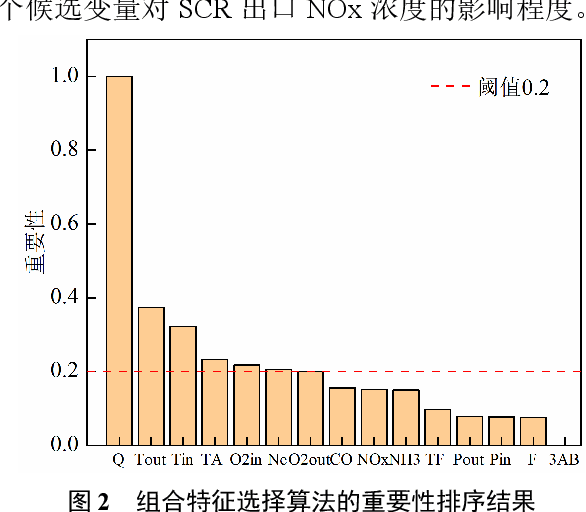

Abstract:Aiming at the problem that delay time is difficult to determine and prediction accuracy is low in building prediction model of SCR system, a dynamic modeling scheme based on a hybrid of multiple data-driven algorithms was proposed. First, processed abnormal values and normalized the data. To improve the relevance of the input data, used MIC to estimate delay time and reconstructed production data. Then used combined feature selection method to determine input variables. To further mine data information, VMD was used to decompose input time series. Finally, established NOx emission prediction model combining ELM and EC model. Experimental results based on actual historical operating data show that the MAPE of predicted results is 2.61%. Model sensitivity analysis shows that besides the amount of ammonia injection, the inlet oxygen concentration and the flue gas temperature have a significant impact on NOx emission, which should be considered in SCR process control and optimization.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge