Sagar Iyer

A machine learning accelerated inverse design of underwater acoustic polyurethane coatings with cylindrical voids

Mar 02, 2022

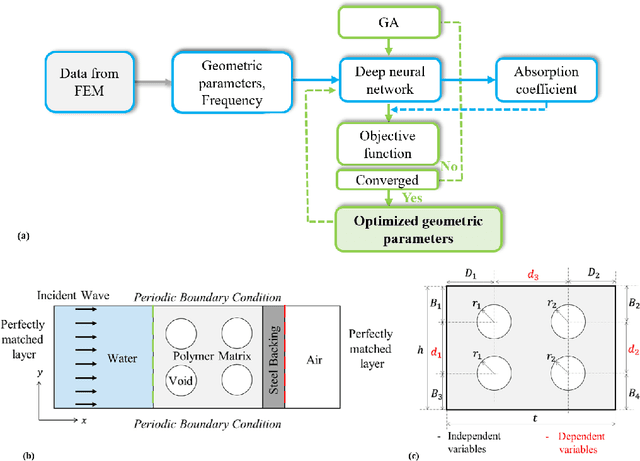

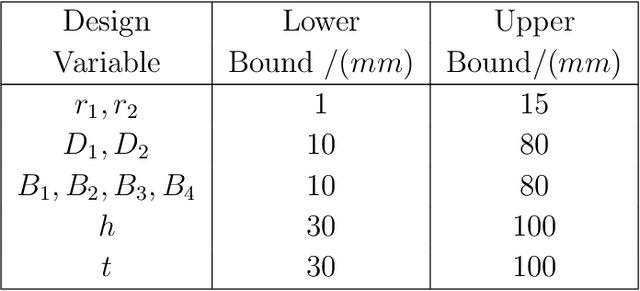

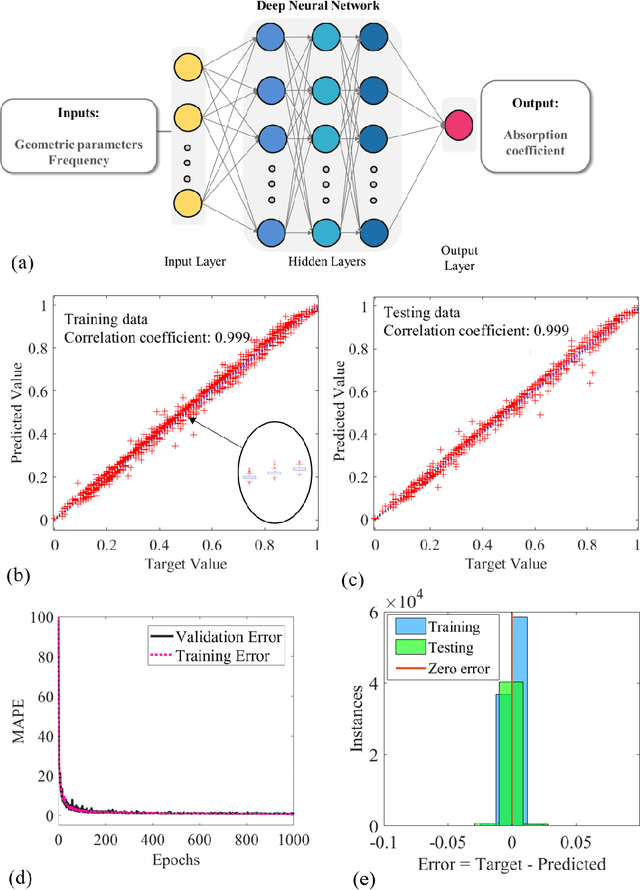

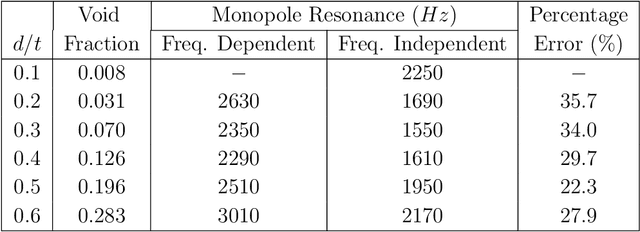

Abstract:Here, we report the development of a detailed "Materials Informatics" framework for the design of acoustic coatings for underwater sound attenuation through integrating Machine Learning (ML) and statistical optimization algorithms with a Finite Element Model (FEM). The finite element models were developed to simulate the realistic performance of the acoustic coatings based on polyurethane (PU) elastomers with embedded cylindrical voids. The FEM results revealed that the frequency-dependent viscoelastic behavior of the polyurethane matrix has a significant impact on the magnitude and frequency of the absorption peak associated with the cylinders at low frequencies, which has been commonly ignored in previous studies on similar systems. The data generated from the FEM was used to train a Deep Neural Network (DNN) to accelerate the design process, and subsequently, was integrated with a Genetic Algorithm (GA) to determine the optimal geometric parameters of the cylinders to achieve maximized, broadband, low-frequency waterborne sound attenuation. A significant, broadband, low-frequency attenuation is achieved by optimally configuring the layers of cylindrical voids and using attenuation mechanisms, including Fabry-P\'erot resonance and Bragg scattering of the layers of voids. Integration of the machine learning technique into the optimization algorithm further accelerated the exploration of the high dimensional design space for the targeted performance. The developed DNN exhibited significantly increased speed (by a factor of $4.5\times 10^3$ ) in predicting the absorption coefficient compared to the conventional FEM(s). Therefore, the acceleration brought by the materials informatics framework brings a paradigm shift to the design and development of acoustic coatings compared to the conventional trial-and-error practices.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge