Rehan Younas

Predicting and Accelerating Nanomaterials Synthesis Using Machine Learning Featurization

Sep 12, 2024

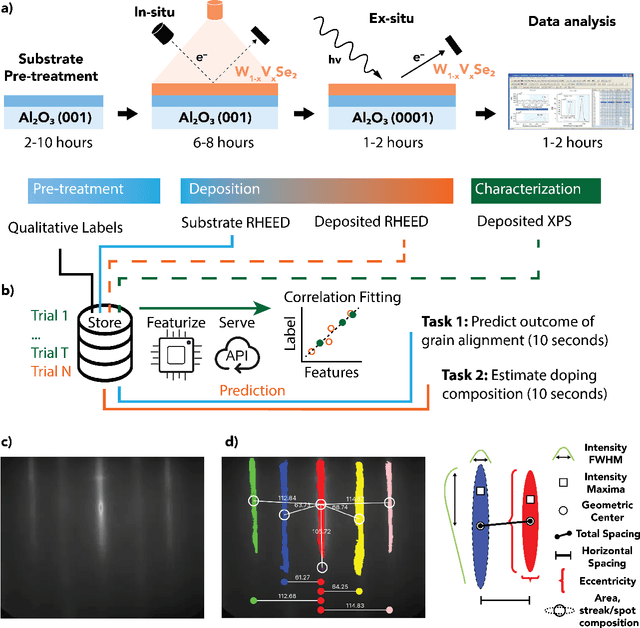

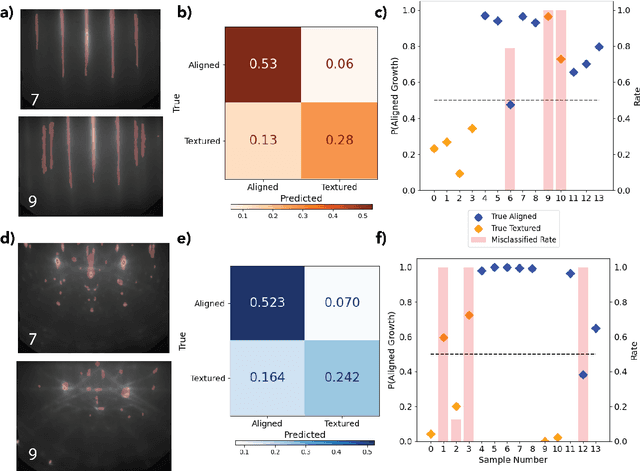

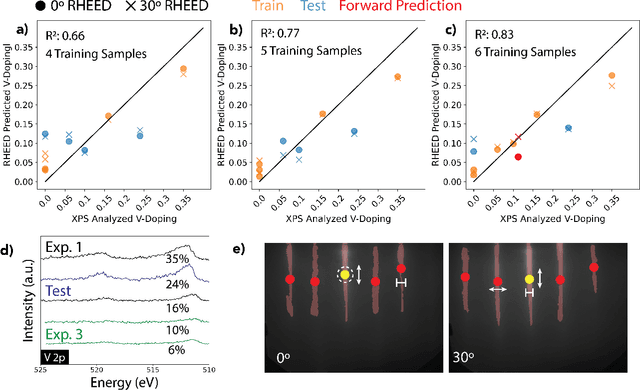

Abstract:Solving for the complex conditions of materials synthesis and processing requires analyzing information gathered from multiple modes of characterization. Currently, quantitative information is extracted serially with manual tools and intuition, constraining the feedback cycle for process optimization. We use machine learning to automate and generalize feature extraction for in-situ reflection high-energy electron diffraction (RHEED) data to establish quantitatively predictive relationships in small sets ($\sim$10) of expert-labeled data, and apply these to save significant time on subsequent epitaxially grown samples. The fidelity of these relationships is tested on a representative material system ($W_{1-x}V_xSe2$ growth on c-plane sapphire substrate (0001)) at two stages of synthesis with two aims: 1) predicting the grain alignment of the deposited film from the pre-growth substrate surface data, and 2) estimating the vanadium (V) dopant concentration using in-situ RHEED as a proxy for ex-situ methods (e.g. x-ray photoelectron spectroscopy). Both tasks are accomplished using the same set of materials agnostic core features, eliminating the need to retrain for specific systems and leading to a potential 80\% time saving over a 100 sample synthesis campaign. These predictions provide guidance for recipe adjustments to avoid doomed trials, reduce follow-on characterization, and improve control resolution for materials synthesis, ultimately accelerating materials discovery and commercial scale-up.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge