Matthias Faes

On Fractional Moment Estimation from Polynomial Chaos Expansion

Mar 04, 2024

Abstract:Fractional statistical moments are utilized for various tasks of uncertainty quantification, including the estimation of probability distributions. However, an estimation of fractional statistical moments of costly mathematical models by statistical sampling is challenging since it is typically not possible to create a large experimental design due to limitations in computing capacity. This paper presents a novel approach for the analytical estimation of fractional moments, directly from polynomial chaos expansions. Specifically, the first four statistical moments obtained from the deterministic PCE coefficients are used for an estimation of arbitrary fractional moments via H\"{o}lder's inequality. The proposed approach is utilized for an estimation of statistical moments and probability distributions in three numerical examples of increasing complexity. Obtained results show that the proposed approach achieves a superior performance in estimating the distribution of the response, in comparison to a standard Latin hypercube sampling in the presented examples.

Process Monitoring of Extrusion Based 3D Printing via Laser Scanning

Dec 07, 2016

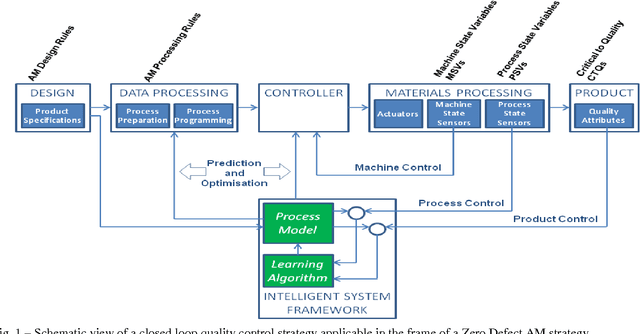

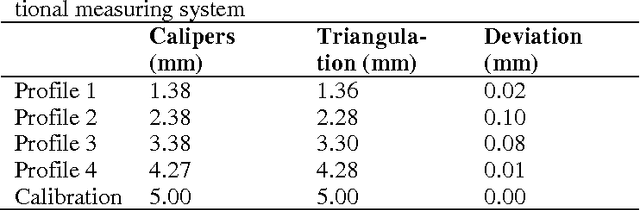

Abstract:Extrusion based 3D Printing (E3DP) is an Additive Manufacturing (AM) technique that extrudes thermoplastic polymer in order to build up components using a layerwise approach. Hereby, AM typically requires long production times in comparison to mass production processes such as Injection Molding. Failures during the AM process are often only noticed after build completion and frequently lead to part rejection because of dimensional inaccuracy or lack of mechanical performance, resulting in an important loss of time and material. A solution to improve the accuracy and robustness of a manufacturing technology is the integration of sensors to monitor and control process state-variables online. In this way, errors can be rapidly detected and possibly compensated at an early stage. To achieve this, we integrated a modular 2D laser triangulation scanner into an E3DP machine and analyzed feedback signals. A 2D laser triangulation scanner was selected here owing to the very compact size, achievable accuracy and the possibility of capturing geometrical 3D data. Thus, our implemented system is able to provide both quantitative and qualitative information. Also, in this work, first steps towards the development of a quality control loop for E3DP processes are presented and opportunities are discussed.

* International Conference on Polymers and Moulds Innovations(PMI) 2014

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge