Mahsa Amiri

A preliminary data fusion study to assess the feasibility of Foundation Process-Property Models in Laser Powder Bed Fusion

Mar 20, 2025Abstract:Foundation models are at the forefront of an increasing number of critical applications. In regards to technologies such as additive manufacturing (AM), these models have the potential to dramatically accelerate process optimization and, in turn, design of next generation materials. A major challenge that impedes the construction of foundation process-property models is data scarcity. To understand the impact of this challenge, and since foundation models rely on data fusion, in this work we conduct controlled experiments where we focus on the transferability of information across different material systems and properties. More specifically, we generate experimental datasets from 17-4 PH and 316L stainless steels (SSs) in Laser Powder Bed Fusion (LPBF) where we measure the effect of five process parameters on porosity and hardness. We then leverage Gaussian processes (GPs) for process-property modeling in various configurations to test if knowledge about one material system or property can be leveraged to build more accurate machine learning models for other material systems or properties. Through extensive cross-validation studies and probing the GPs' interpretable hyperparameters, we study the intricate relation among data size and dimensionality, complexity of the process-property relations, noise, and characteristics of machine learning models. Our findings highlight the need for structured learning approaches that incorporate domain knowledge in building foundation process-property models rather than relying on uninformed data fusion in data-limited applications.

Unveiling Processing--Property Relationships in Laser Powder Bed Fusion: The Synergy of Machine Learning and High-throughput Experiments

Aug 30, 2024

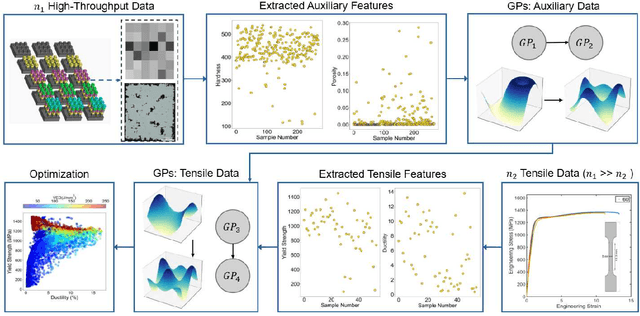

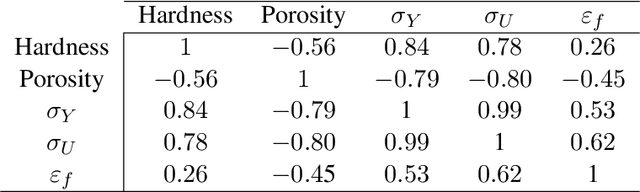

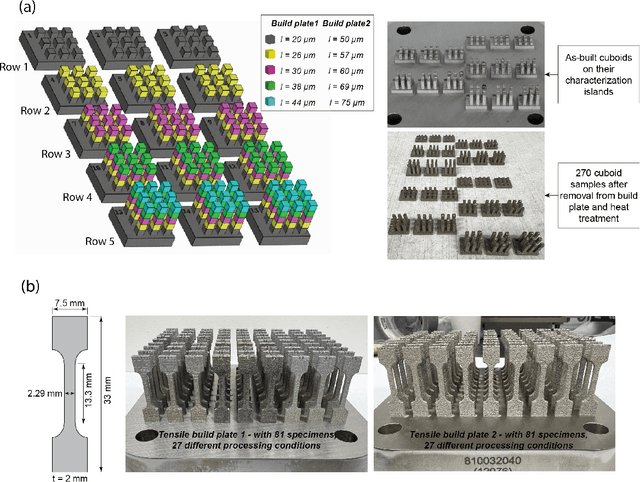

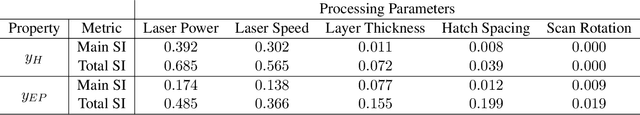

Abstract:Achieving desired mechanical properties in additive manufacturing requires many experiments and a well-defined design framework becomes crucial in reducing trials and conserving resources. Here, we propose a methodology embracing the synergy between high-throughput (HT) experimentation and hierarchical machine learning (ML) to unveil the complex relationships between a large set of process parameters in Laser Powder Bed Fusion (LPBF) and selected mechanical properties (tensile strength and ductility). The HT method envisions the fabrication of small samples for rapid automated hardness and porosity characterization, and a smaller set of tensile specimens for more labor-intensive direct measurement of yield strength and ductility. The ML approach is based on a sequential application of Gaussian processes (GPs) where the correlations between process parameters and hardness/porosity are first learnt and subsequently adopted by the GPs that relate strength and ductility to process parameters. Finally, an optimization scheme is devised that leverages these GPs to identify the processing parameters that maximize combinations of strength and ductility. By founding the learning on larger easy-to-collect and smaller labor-intensive data, we reduce the reliance on expensive characterization and enable exploration of a large processing space. Our approach is material-agnostic and herein we demonstrate its application on 17-4PH stainless steel.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge