Lukas Malburg

From Internet of Things Data to Business Processes: Challenges and a Framework

May 14, 2024

Abstract:The IoT and Business Process Management (BPM) communities co-exist in many shared application domains, such as manufacturing and healthcare. The IoT community has a strong focus on hardware, connectivity and data; the BPM community focuses mainly on finding, controlling, and enhancing the structured interactions among the IoT devices in processes. While the field of Process Mining deals with the extraction of process models and process analytics from process event logs, the data produced by IoT sensors often is at a lower granularity than these process-level events. The fundamental questions about extracting and abstracting process-related data from streams of IoT sensor values are: (1) Which sensor values can be clustered together as part of process events?, (2) Which sensor values signify the start and end of such events?, (3) Which sensor values are related but not essential? This work proposes a framework to semi-automatically perform a set of structured steps to convert low-level IoT sensor data into higher-level process events that are suitable for process mining. The framework is meant to provide a generic sequence of abstract steps to guide the event extraction, abstraction, and correlation, with variation points for plugging in specific analysis techniques and algorithms for each step. To assess the completeness of the framework, we present a set of challenges, how they can be tackled through the framework, and an example on how to instantiate the framework in a real-world demonstration from the field of smart manufacturing. Based on this framework, future research can be conducted in a structured manner through refining and improving individual steps.

Using Semantic Web Services for AI-Based Research in Industry 4.0

Jul 07, 2020

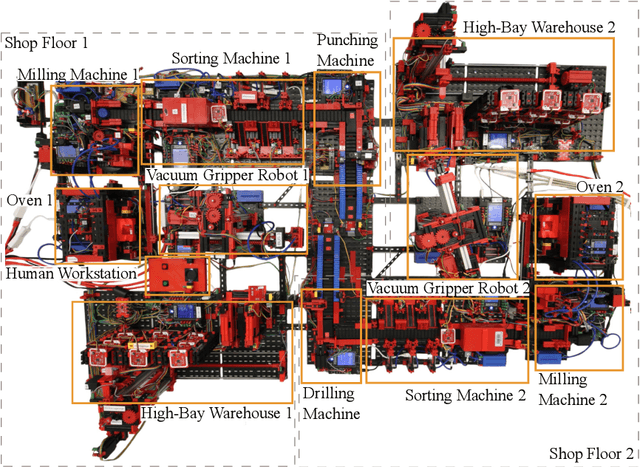

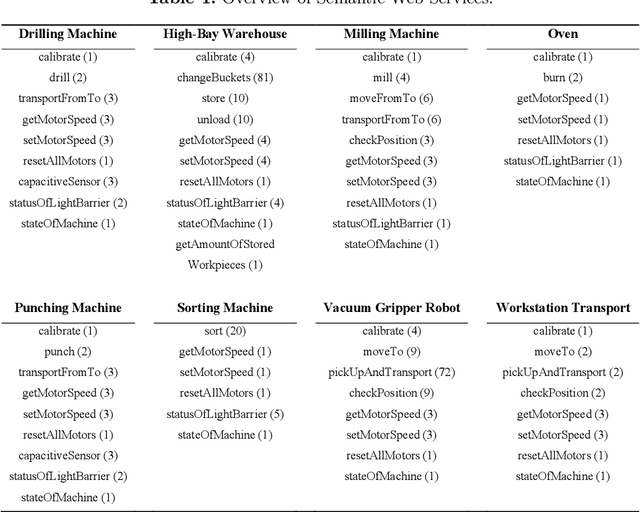

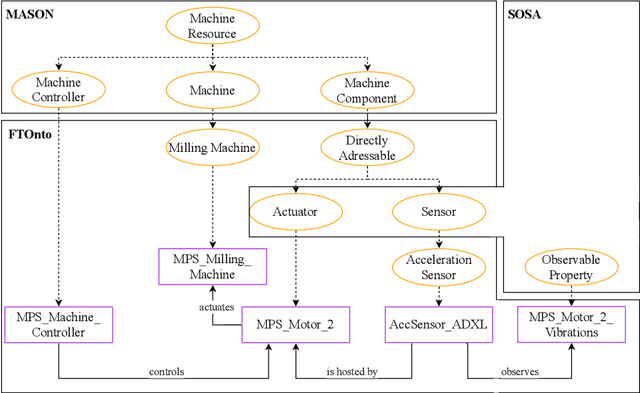

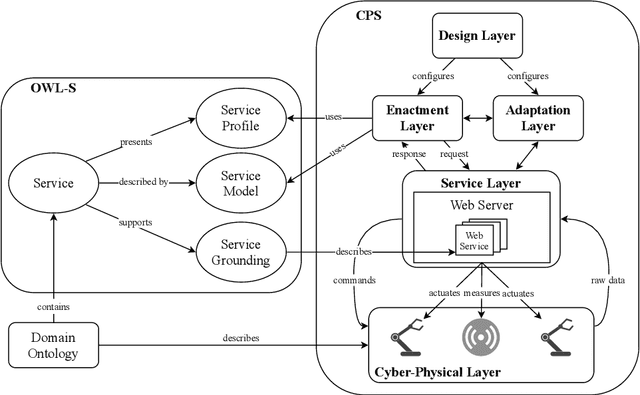

Abstract:The transition to Industry 4.0 requires smart manufacturing systems that are easily configurable and provide a high level of flexibility during manufacturing in order to achieve mass customization or to support cloud manufacturing. To realize this, Cyber-Physical Systems (CPSs) combined with Artificial Intelligence (AI) methods find their way into manufacturing shop floors. For using AI methods in the context of Industry 4.0, semantic web services are indispensable to provide a reasonable abstraction of the underlying manufacturing capabilities. In this paper, we present semantic web services for AI-based research in Industry 4.0. Therefore, we developed more than 300 semantic web services for a physical simulation factory based on Web Ontology Language for Web Services (OWL-S) and Web Service Modeling Ontology (WSMO) and linked them to an already existing domain ontology for intelligent manufacturing control. Suitable for the requirements of CPS environments, our pre- and postconditions are verified in near real-time by invoking other semantic web services in contrast to complex reasoning within the knowledge base. Finally, we evaluate our implementation by executing a cyber-physical workflow composed of semantic web services using a workflow management system.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge