Lino Marques

An in-Contact Robotic System for the Process of Desoldering PCB Components

Mar 08, 2024

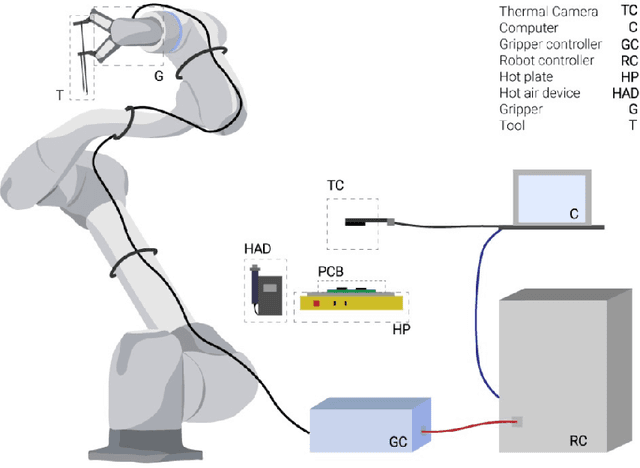

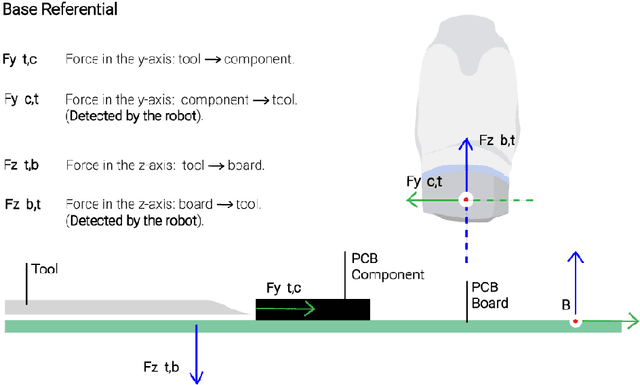

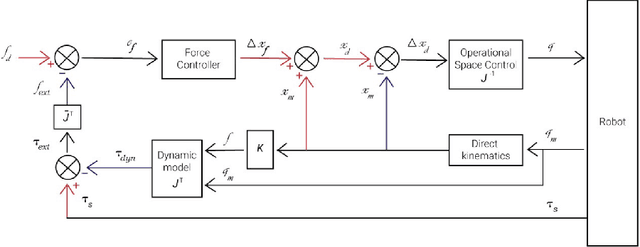

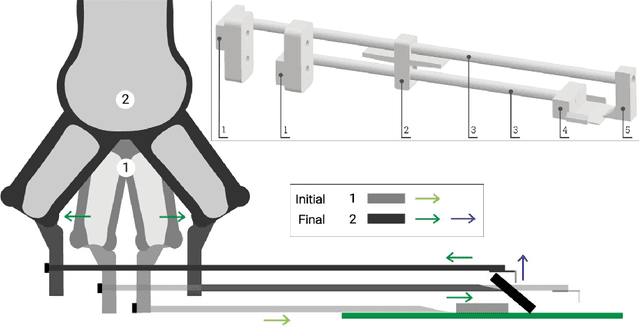

Abstract:The disposal and recycling of electronic waste (e-waste) is a global challenge. The disassembly of components is a crucial step towards an efficient recycling process, avoiding the destructive methods. Although most disassembly work is still done manually due to the diversity and complexity of components, there is a growing interest in developing automated methods to improve efficiency and reduce labor costs. This study aims to robotize the desoldering process and extracting components from printed circuit boards (PCBs), with the goal of automating the process as much as possible. The proposed strategy consists of several phases, including the controlled contact of the robotic tool with the PCB components. A specific tool was developed to apply a controlled force against the PCB component, removing it from the board. The results demonstrate that it is feasible to remove the PCB components with a high success rate (approximately 100% for the bigger PCB components).

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge