Levent Burak kara

VIRL: Volume-Informed Representation Learning towards Few-shot Manufacturability Estimation

Jun 18, 2024

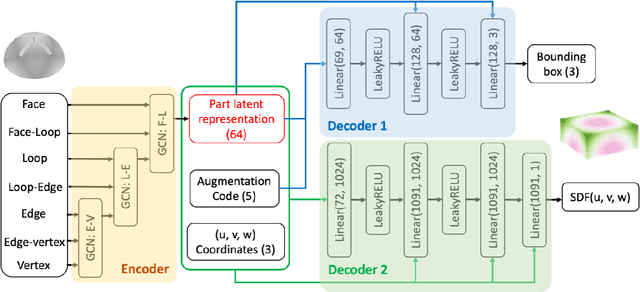

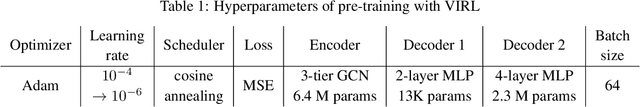

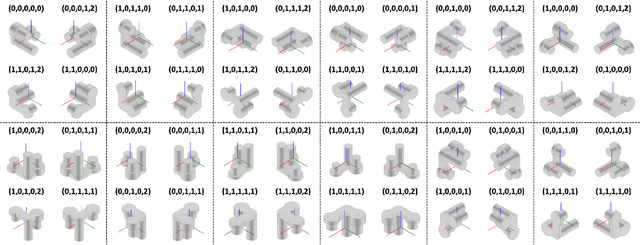

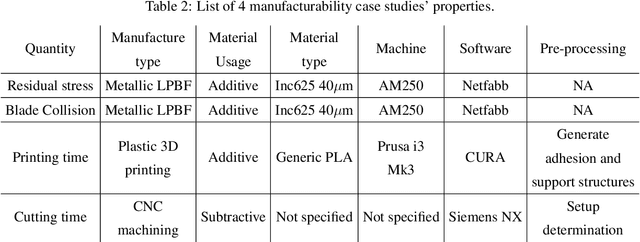

Abstract:Designing for manufacturing poses significant challenges in part due to the computation bottleneck of Computer-Aided Manufacturing (CAM) simulations. Although deep learning as an alternative offers fast inference, its performance is dependently bounded by the need for abundant training data. Representation learning, particularly through pre-training, offers promise for few-shot learning, aiding in manufacturability tasks where data can be limited. This work introduces VIRL, a Volume-Informed Representation Learning approach to pre-train a 3D geometric encoder. The pretrained model is evaluated across four manufacturability indicators obtained from CAM simulations: subtractive machining (SM) time, additive manufacturing (AM) time, residual von Mises stress, and blade collisions during Laser Power Bed Fusion process. Across all case studies, the model pre-trained by VIRL shows substantial enhancements on demonstrating improved generalizability with limited data and superior performance with larger datasets. Regarding deployment strategy, case-specific phenomenon exists where finetuning VIRL-pretrained models adversely affects AM tasks with limited data but benefits SM time prediction. Moreover, the efficacy of Low-rank adaptation (LoRA), which balances between probing and finetuning, is explored. LoRA shows stable performance akin to probing with limited data, while achieving a higher upper bound than probing as data size increases, without the computational costs of finetuning. Furthermore, static normalization of manufacturing indicators consistently performs well across tasks, while dynamic normalization enhances performance when a reliable task dependent input is available.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge