Jan Lundgren

An artificial neural network-based system for detecting machine failures using tiny sound data: A case study

Sep 23, 2022

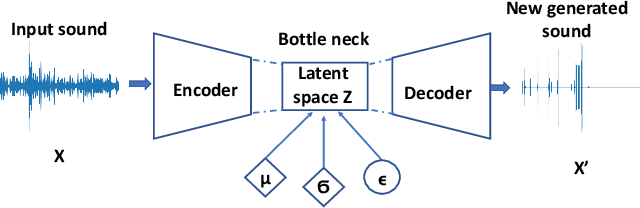

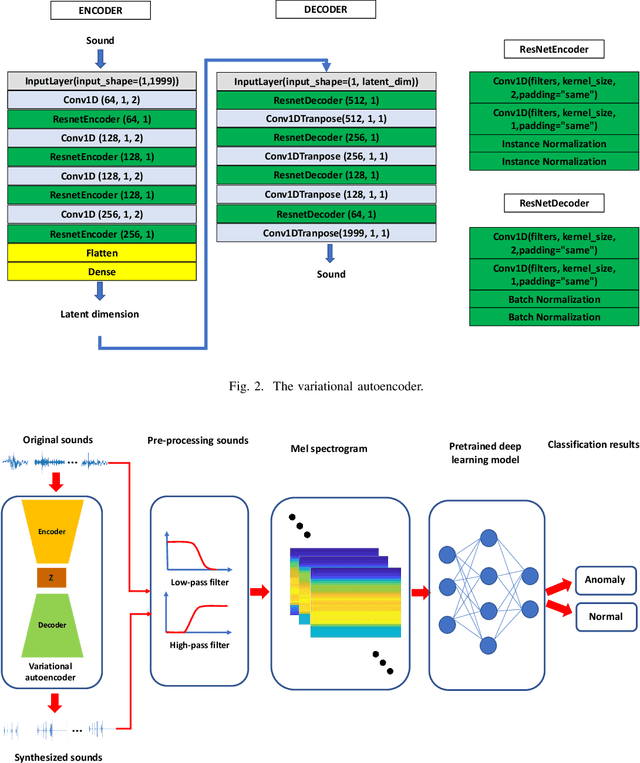

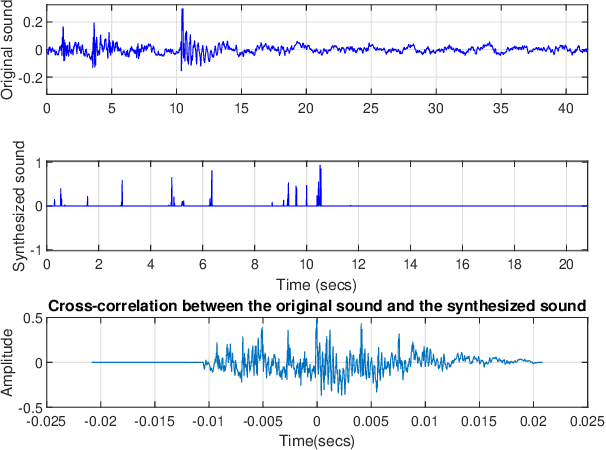

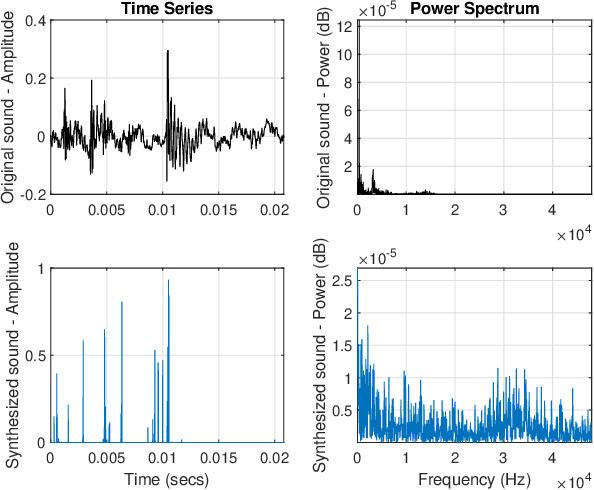

Abstract:In an effort to advocate the research for a deep learning-based machine failure detection system, we present a case study of our proposed system based on a tiny sound dataset. Our case study investigates a variational autoencoder (VAE) for augmenting a small drill sound dataset from Valmet AB. A Valmet dataset contains 134 sounds that have been divided into two categories: "Anomaly" and "Normal" recorded from a drilling machine in Valmet AB, a company in Sundsvall, Sweden that supplies equipment and processes for the production of biofuels. Using deep learning models to detect failure drills on such a small sound dataset is typically unsuccessful. We employed a VAE to increase the number of sounds in the tiny dataset by synthesizing new sounds from original sounds. The augmented dataset was created by combining these synthesized sounds with the original sounds. We used a high-pass filter with a passband frequency of 1000 Hz and a low-pass filter with a passband frequency of 22\kern 0.16667em000 Hz to pre-process sounds in the augmented dataset before transforming them to Mel spectrograms. The pre-trained 2D-CNN Alexnet was then trained using these Mel spectrograms. When compared to using the original tiny sound dataset to train pre-trained Alexnet, using the augmented sound dataset enhanced the CNN model's classification results by 6.62\%(94.12\% when trained on the augmented dataset versus 87.5\% when trained on the original dataset).

Denoising Induction Motor Sounds Using an Autoencoder

Aug 08, 2022

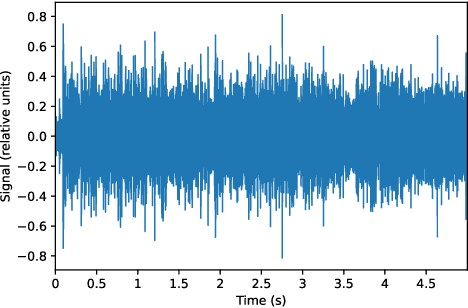

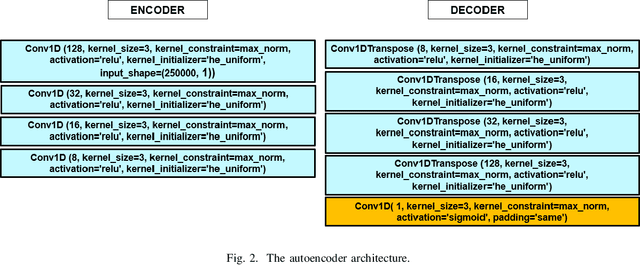

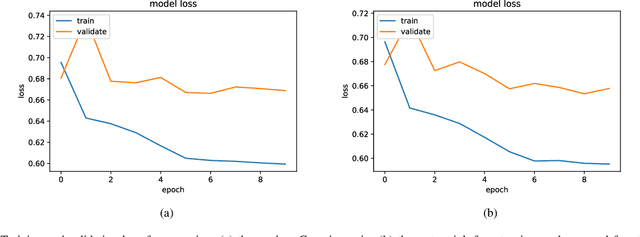

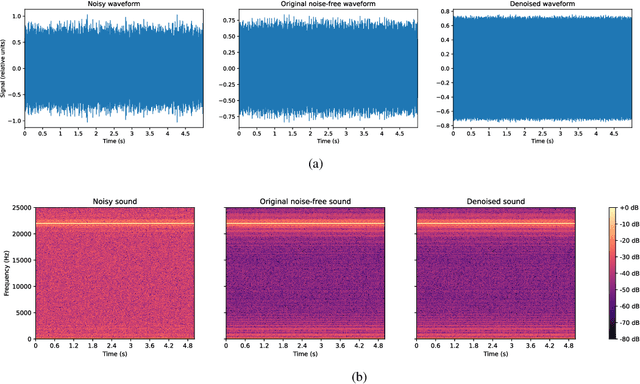

Abstract:Denoising is the process of removing noise from sound signals while improving the quality and adequacy of the sound signals. Denoising sound has many applications in speech processing, sound events classification, and machine failure detection systems. This paper describes a method for creating an autoencoder to map noisy machine sounds to clean sounds for denoising purposes. There are several types of noise in sounds, for example, environmental noise and generated frequency-dependent noise from signal processing methods. Noise generated by environmental activities is environmental noise. In the factory, environmental noise can be created by vehicles, drilling, people working or talking in the survey area, wind, and flowing water. Those noises appear as spikes in the sound record. In the scope of this paper, we demonstrate the removal of generated noise with Gaussian distribution and the environmental noise with a specific example of the water sink faucet noise from the induction motor sounds. The proposed method was trained and verified on 49 normal function sounds and 197 horizontal misalignment fault sounds from the Machinery Fault Database (MAFAULDA). The mean square error (MSE) was used as the assessment criteria to evaluate the similarity between denoised sounds using the proposed autoencoder and the original sounds in the test set. The MSE is below or equal to 0.14 when denoise both types of noises on 15 testing sounds of the normal function category. The MSE is below or equal to 0.15 when denoising 60 testing sounds on the horizontal misalignment fault category. The low MSE shows that both the generated Gaussian noise and the environmental noise were almost removed from the original sounds with the proposed trained autoencoder.

Detecting Drill Failure in the Small Short-sound Drill Dataset

Aug 25, 2021

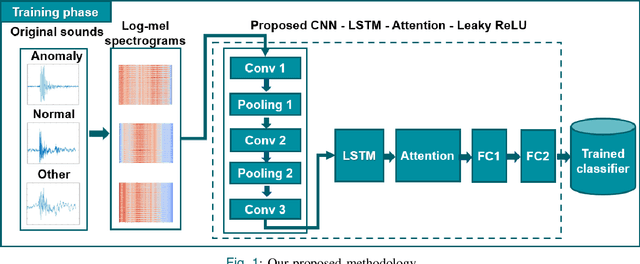

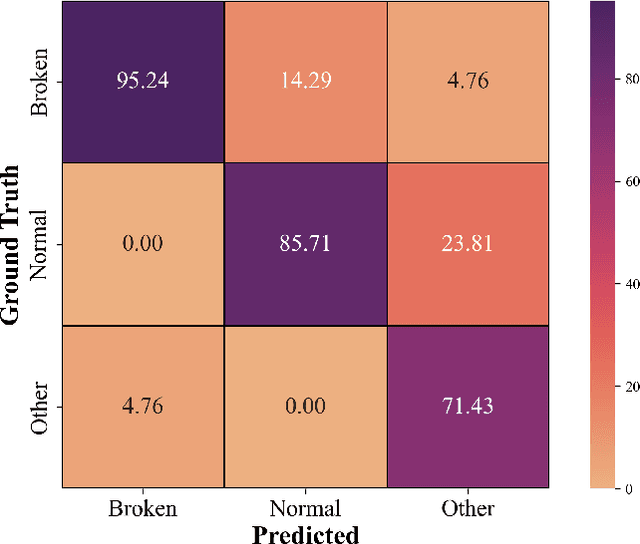

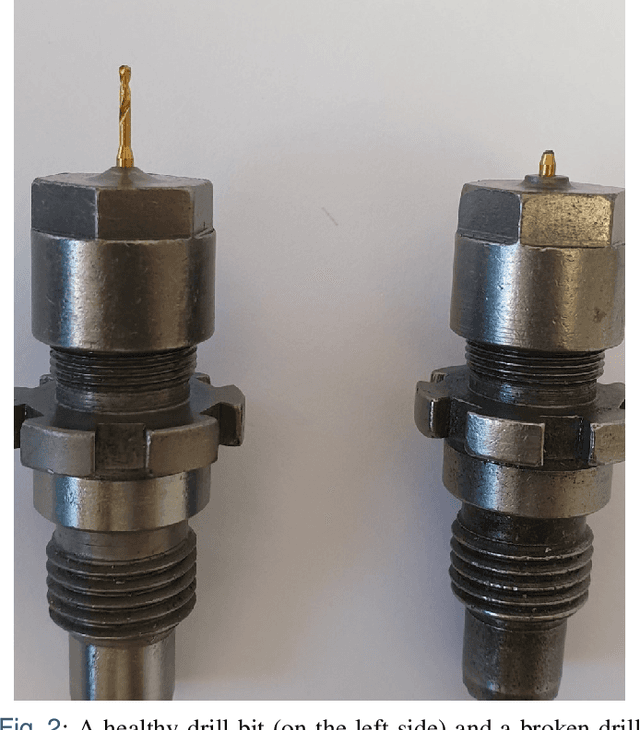

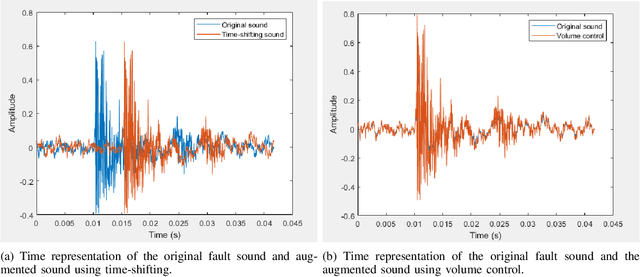

Abstract:Monitoring the conditions of machines is vital in the manufacturing industry. Early detection of faulty components in machines for stopping and repairing the failed components can minimize the downtime of the machine. This article presents an approach to detect the failure occurring in drill machines based on drill sounds from Valmet AB. The drill dataset includes three classes: anomalous sounds, normal sounds, and irrelevant sounds, which are also labeled as ``Broken", ``Normal", and ``Other", respectively. Detecting drill failure effectively remains a challenge due to the following reasons. The waveform of drill sound is complex and short for detection. Additionally, in realistic soundscapes, there are sounds and noise in the context at the same time. Moreover, the balanced dataset is small to apply state-of-the-art deep learning techniques. To overcome these aforementioned difficulties, we augmented sounds to increase the number of sounds in the dataset. We then proposed a convolutional neural network (CNN) combined with a long short-term memory (LSTM) to extract features from log-Mel spectrograms and learn global high-level feature representation for the classification of three classes. A leaky rectified linear unit (Leaky ReLU) was utilized as the activation function for our proposed CNN instead of the rectified linear unit (ReLU). Moreover, we deployed an attention mechanism at the frame level after the LSTM layer to learn long-term global feature representations. As a result, the proposed method reached an overall accuracy of 92.35% for the drill failure detection system.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge