James Watson

A versatile robotic hand with 3D perception, force sensing for autonomous manipulation

Feb 08, 2024Abstract:We describe a force-controlled robotic gripper with built-in tactile and 3D perception. We also describe a complete autonomous manipulation pipeline consisting of object detection, segmentation, point cloud processing, force-controlled manipulation, and symbolic (re)-planning. The design emphasizes versatility in terms of applications, manufacturability, use of commercial off-the-shelf parts, and open-source software. We validate the design by characterizing force control (achieving up to 32N, controllable in steps of 0.08N), force measurement, and two manipulation demonstrations: assembly of the Siemens gear assembly problem, and a sensor-based stacking task requiring replanning. These demonstrate robust execution of long sequences of sensor-based manipulation tasks, which makes the resulting platform a solid foundation for researchers in task-and-motion planning, educators, and quick prototyping of household, industrial and warehouse automation tasks.

Optimal decision making in robotic assembly and other trial-and-error tasks

Jan 25, 2023

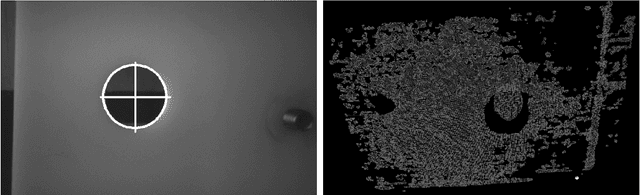

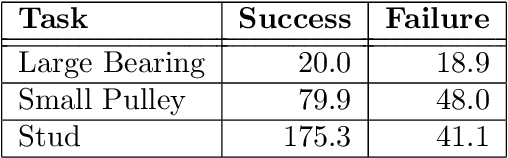

Abstract:Uncertainty in perception, actuation, and the environment often require multiple attempts for a robotic task to be successful. We study a class of problems providing (1) low-entropy indicators of terminal success / failure, and (2) unreliable (high-entropy) data to predict the final outcome of an ongoing task. Examples include a robot trying to connect with a charging station, parallel parking, or assembling a tightly-fitting part. The ability to restart after predicting failure early, versus simply running to failure, can significantly decrease the makespan, that is, the total time to completion, with the drawback of potentially short-cutting an otherwise successful operation. Assuming task running times to be Poisson distributed, and using a Markov Jump process to capture the dynamics of the underlying Markov Decision Process, we derive a closed form solution that predicts makespan based on the confusion matrix of the failure predictor. This allows the robot to learn failure prediction in a production environment, and only adopt a preemptive policy when it actually saves time. We demonstrate this approach using a robotic peg-in-hole assembly problem using a real robotic system. Failures are predicted by a dilated convolutional network based on force-torque data, showing an average makespan reduction from 101s to 81s (N=120, p<0.05). We posit that the proposed algorithm generalizes to any robotic behavior with an unambiguous terminal reward, with wide ranging applications on how robots can learn and improve their behaviors in the wild.

Autonomous Industrial Assembly using Force, Torque, and RGB-D sensing

Feb 07, 2020

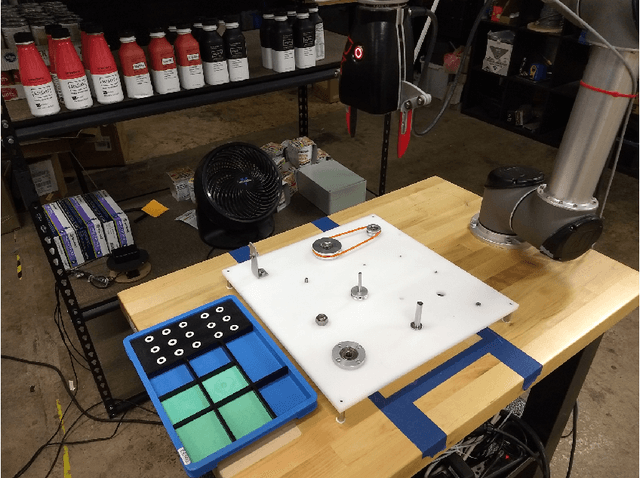

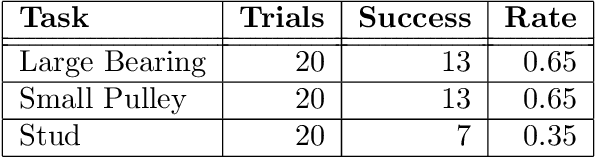

Abstract:We present algorithms and results for a robotic manipulation system that was designed to be easily programmable and adaptable to various tasks common to industrial setting, which is inspired by the Industrial Assembly Challenge at the 2018 World Robotics Summit in Tokyo. This challenge included assembly of standard, commercially available industrial parts into 2D and 3D assemblies. We demonstrate three tasks that can be classified into "peg-in-hole" and "hole-on-peg" tasks and identify two canonical algorithms: spiral-based search and tilting insertion. Both algorithms use hand-coded thresholds in the force and torque domains to detect critical points in the assembly. After briefly summarizing the state of the art in research, we describe the strategy and approach utilized by the tested system, how it's design bears on its performance, statistics on 20 experimental trials for each task, lessons learned during the development of the system, and open research challenges that still remain.

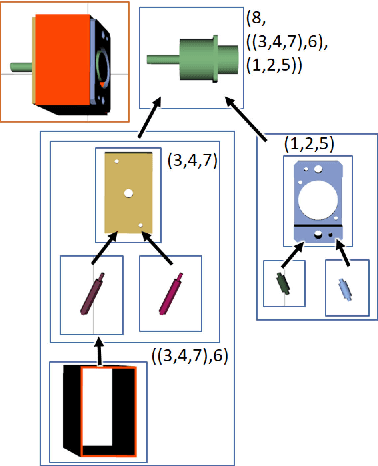

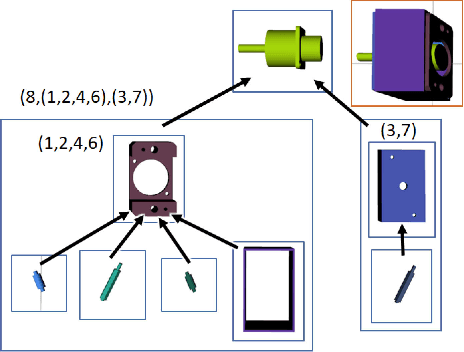

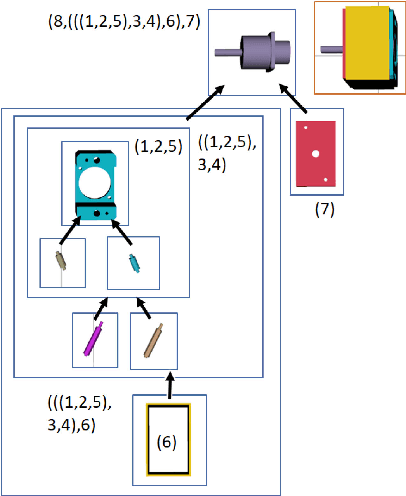

Assembly Planning by Subassembly Decomposition Using Blocking Reduction

Jul 08, 2019

Abstract:The sequence in which a complex product is assembled directly impacts the ease and efficiency of the assembly process, whether executed by a human or a robot. A sequence that gives the assembler the greatest freedom of movement is therefore desirable. Our main contribution is an expression of obstruction relationships between parts as a disassembly interference graph (DIG). We validate this heuristic by developing a disassembly sequence planner that partitions assemblies in a way that prioritizes access to parts, resulting in plans that are comparable in efficiency to two state-of-the-art assembly methods in terms of total plan length. Using DIG, our method generates successive subassembly decompositions, yielding a tree structure that makes parallization opportunities apparent. Our planner generates viable disassembly plans by minimizing our part blockage measure, and thereby demonstrates that this measure is a valuable addition to the Assembly Sequence Planning toolkit.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge