Henrik Riedel

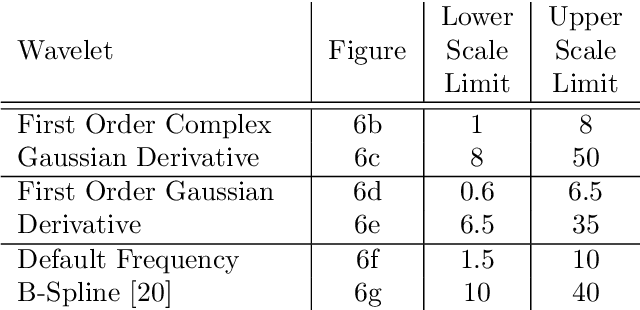

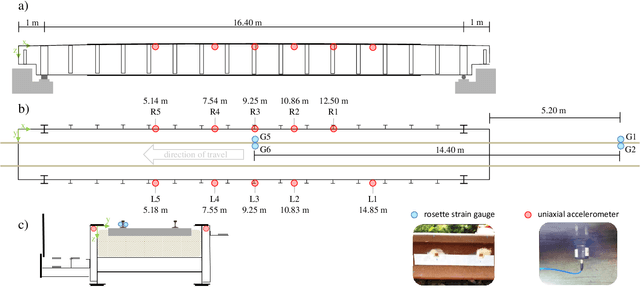

Virtual Axle Detector based on Analysis of Bridge Acceleration Measurements by Fully Convolutional Network

Jul 08, 2022

Abstract:In the practical application of the Bridge Weigh-In-Motion (BWIM) methods, the position of the wheels or axles during the passage of a vehicle is in most cases a prerequisite. To avoid the use of conventional axle detectors and bridge type specific methods, we propose a novel method for axle detection through the placement of accelerometers at any point of a bridge. In order to develop a model that is as simple and comprehensible as possible, the axle detection task is implemented as a binary classification problem instead of a regression problem. The model is implemented as a Fully Convolutional Network to process signals in the form of Continuous Wavelet Transforms. This allows passages of any length to be processed in a single step with maximum efficiency while utilising multiple scales in a single evaluation. This enables our method to use acceleration signals at any location of the bridge structure serving as Virtual Axle Detectors (VADs) without being limited to specific structural types of bridges. To test the proposed method, we analysed 3787 train passages recorded on a steel trough railway bridge of a long-distance traffic line. Our results on the measurement data show that our model detects 95% of the axes, thus, 128,599 of 134,800 previously unseen axles were correctly detected. In total, 90% of the axles can be detected with a maximum spatial error of 20cm, with a maximum velocity of $v_{\mathrm{max}}=56,3~\mathrm{m/s}$. The analysis shows that our developed model can use accelerometers as VADs even under real operating conditions.

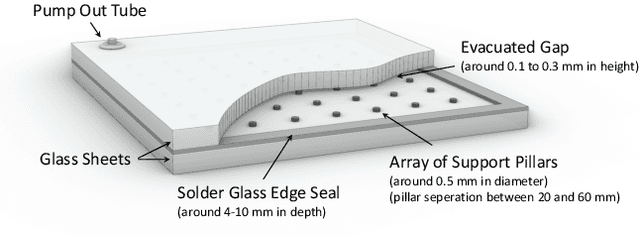

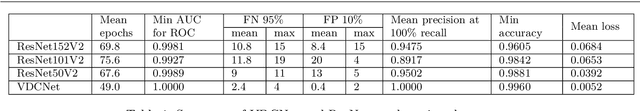

Automated Quality Control of Vacuum Insulated Glazing by Convolutional Neural Network Image Classification

Oct 15, 2021

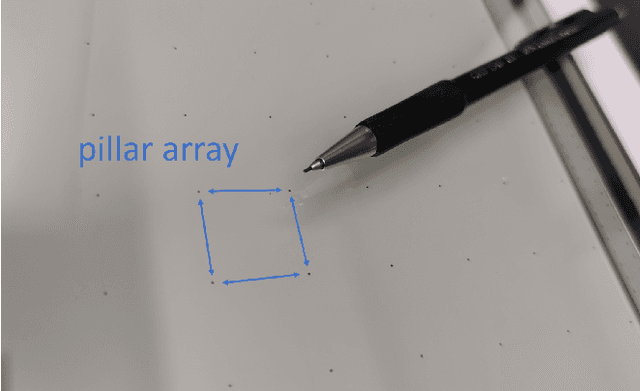

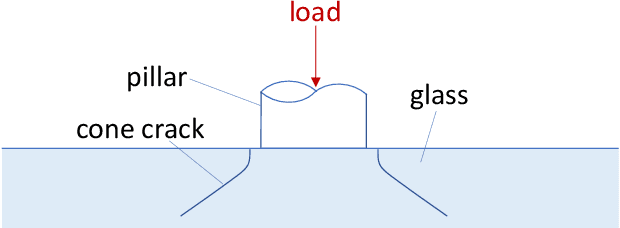

Abstract:Vacuum Insulated Glazing (VIG) is a highly thermally insulating window technology, which boasts an extremely thin profile and lower weight as compared to gas-filled insulated glazing units of equivalent performance. The VIG is a double-pane configuration with a submillimeter vacuum gap between the panes and therefore under constant atmospheric pressure over their service life. Small pillars are positioned between the panes to maintain the gap, which can damage the glass reducing the lifetime of the VIG unit. To efficiently assess any surface damage on the glass, an automated damage detection system is highly desirable. For the purpose of classifying the damage, we have developed, trained, and tested a deep learning computer vision system using convolutional neural networks. The classification model flawlessly classified the test dataset with an area under the curve (AUC) for the receiver operating characteristic (ROC) of 100%. We have automatically cropped the images down to their relevant information by using Faster-RCNN to locate the position of the pillars. We employ the state-of-the-art methods Grad-CAM and Score-CAM of explainable Artificial Intelligence (XAI) to provide an understanding of the internal mechanisms and were able to show that our classifier outperforms ResNet50V2 for identification of crack locations and geometry. The proposed methods can therefore be used to detect systematic defects even without large amounts of training data. Further analyses of our model's predictive capabilities demonstrates its superiority over state-of-the-art models (ResNet50V2, ResNet101V2 and ResNet152V2) in terms of convergence speed, accuracy, precision at 100% recall and AUC for ROC.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge